Electronics Industry

The electronics industry has transformed our world over the last decades, and the Covid-19 pandemic only accelerated the digitization and virtualization of work and society. The adoption of electronic technologies has increased business revenue and productivity, enhanced product quality, reduced operational costs, and improved quality of living for people around the world. As electronics become even more crucial for human health, productivity, transportation, and entertainment, electronics developers must meet increasing demands for higher quality and improved functionality.

While innovation in electronics has come a long way, developers are still limited by the materials in their products. New designs can only succeed if they are durable, functional, and safe. Defective products not only pose safety and reputation risks, but their recalls also incur massive economic losses. Electronics labs across industries and around the world use TA Instruments’ | Waters line of customizable material analysis instruments to characterize their products from material selection to end-use performance.

Application Solutions

Printed circuit boards (PCB) are the foundation of most electronic devices. Manufacturers measure printed circuit boards’ thermal stability to determine their performance under different temperatures and develop PCBs that resist breaking down due to heat and stress. Thermal stability is affected by thermal conductivity, glass transitions, and coefficient of thermal expansion, all of which are measured by thermal analysis instruments. Mechanical stability and durability is affected by material stiffness and fatigue resistance of electronic assemblies.

In addition to measuring whole PCB qualities, manufacturers also perform more detailed testing on PCB materials, such as the cured laminate and adhesive that hold wires in place and strengthen PCB structure. Since their cure is essential for end-use performance and reliability, manufacturers use thermal analysis to rapidly evaluate degree of cure and adjust their formulations. The degree of cure in thermosets can be determined through measuring the glass transition temperature (Tg) or a residual cure exotherm using differential scanning calorimetry (DSC). From small components to finished product, PCBs are improved at all stages by superior material characterization.

Material strength

- Young’s modulus, yield strength, ultimate strength, elongation at break

- Fatigue and durability, S-N curves

- Strength vs. temperature

Final assembly strength

- Bond or joint performance

- Flexural, bending or crush failure points

- Fatigue and durability, S-N curves

- Strength vs temperature

Differential Scanning Calorimetry (DSC)

- Glass Transition Temperature (Tg)

Temperature Range: -180°C to 725°C

Thermogravimetric Analysis (TGA)

- Decomposition Temperatures

- Compositional analysis

SA measures impact of humidity instead of temperature

- HAST test

- Water adsorption

Temperature Range: RT to 1500°C

- Thermal Management Properties

- Thermal Diffusivity

- Thermal Conductivity

- Heat Capacity

Temperature Range: -175°C to 2800°C

Thermomechanical Analysis (TMA)

- Composite or Laminate Material Compatibility

- Failure Analysis

- Glass transition temperature (Tg)

- Coefficient of Thermal Expansion (CTE)

- Softening Points

- Time to delamination

450 RH measures impact of humidity instead of temperature

- Composite or Laminate Material Compatibility

- Failure Analysis

- Swelling or shrinking

- Coefficient of Hygroscopic Expansion (CHE)

Temperature Range: -150°C to 1000°C

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

Organic light emitting diodes (OLEDs) are thin films that emit light when an electric current is applied. OLEDs are used in a variety of everyday electronics including televisions, mobile phones, computer monitors, and display screens. Raw materials for OLED devices must be highly pure to extend the life of the luminescence and quality of the final product. Current research aims to develop OLED screens with brighter, clearer resolutions as well as white OLED solid-state lighting devices. Researchers turn to material science to detect impurities in their OLED materials and optimize their designs for enhanced performance in all end-use conditions.

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

- UV initiated cure time

- Modulus of cure

- Viscosity

- Tg of thin films (DMA)

Temperature Range: -150°C to 600°C

5G offers faster internet speeds, lower latency, and increased connectivity to industries ranging from infrastructure to consumer devices. Materials for 5G devices, including antennas, PCBs, cases, frames, semiconductors, EMCs, and microwave medium ceramics, must be tested and optimized for the final device’s end-use durability and functionality. Especially as researchers explore materials that reduce cost and enhance performance, they use TA Instruments material analysis solutions to assess:

- Dielectric Properties

- Stability

- Mechanical Properties

- Heat Dissipation

- Processability

- Processability (viscosity)

- Shear included dielectric measurements

Temperature Range: -150°C to 600°C

- Thermal Management Properties

- Thermal Diffusivity

- Thermal Conductivity

- Heat Capacity

Temperature Range: -175°C to 2800°C

Thermomechanical Analysis (TMA)

- Composite or Laminate Material Compatibility

- Failure Analysis

- Glass transition temperature (Tg)

- Coefficient of Thermal Expansion (CTE)

- Softening Points

- Time to delamination

450 RH measures impact of humidity instead of temperature

- Composite or Laminate Material Compatibility

- Failure Analysis

- Swelling or shrinking

- Coefficient of Hygroscopic Expansion (CHE)

Temperature Range: -150°C to 1000°C

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

Material strength

- Young’s modulus, yield strength, ultimate strength, elongation at break

- Fatigue and durability, S-N curves

- Strength vs. temperature

Final assembly strength

- Bond or joint performance

- Flexural, bending or crush failure points

- Fatigue and durability, S-N curves

- Strength vs temperature

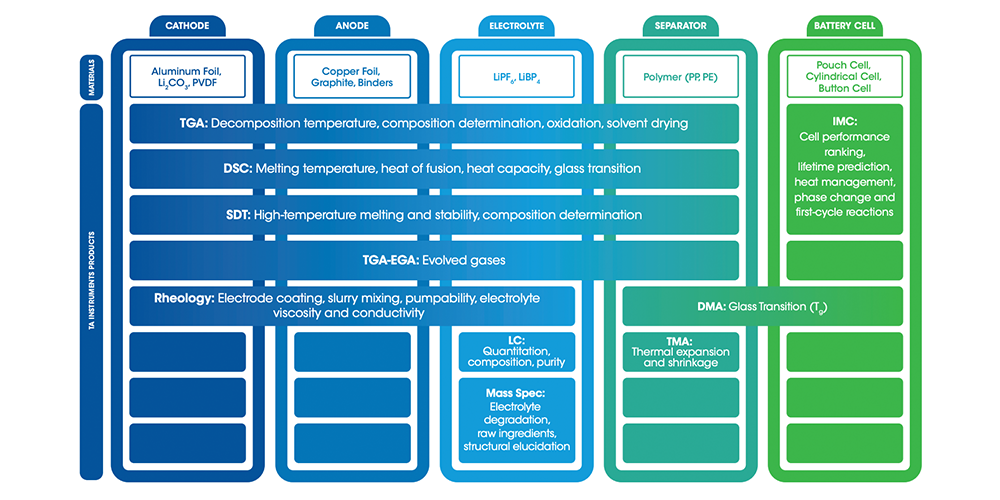

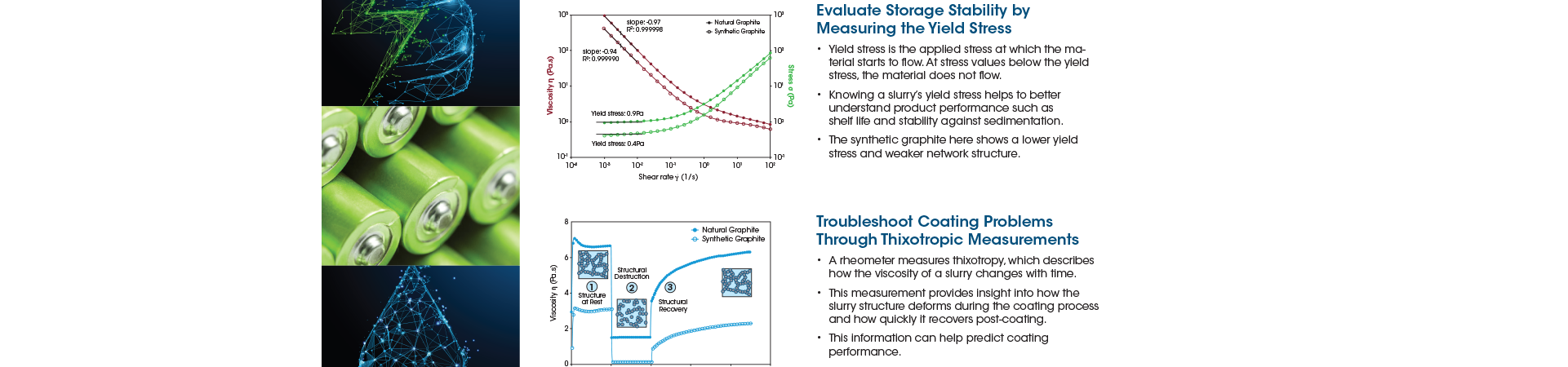

Lithium-ion batteries power consumer electronics, from cell phones to medical devices, and are increasingly being used in electric vehicles and grid energy storage. Although they are already widely used, lithium-ion batteries still have room for improvement in performance, cost, and safety. Researchers are enhancing lithium-ion batteries by optimizing materials in the four main battery parts: the cathode, anode, separator, and electrolyte.

Waters / TA Instruments supports material characterization of lithium-ion batteries through thermal analysis, microcalorimetry, rheology, and mechanical test solutions tailored to battery development. Battery researchers, formulators, and production specialists turn to industry-leading material analysis instrumentation to develop better performing and safer batteries.

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

Material strength

- Young’s modulus, yield strength, ultimate strength, elongation at break

- Fatigue and durability, S-N curves

- Strength vs. temperature

Final assembly strength

- Flexural, bending or crush failure points

- Fatigue and durability, S-N curves

- Strength vs temperature

- Thermal Management Properties

- Thermal Diffusivity

- Thermal Conductivity

- Heat Capacity

Temperature Range: -175°C to 2800°C

- Printed Circuit Boards (PCB)

-

Printed circuit boards (PCB) are the foundation of most electronic devices. Manufacturers measure printed circuit boards’ thermal stability to determine their performance under different temperatures and develop PCBs that resist breaking down due to heat and stress. Thermal stability is affected by thermal conductivity, glass transitions, and coefficient of thermal expansion, all of which are measured by thermal analysis instruments. Mechanical stability and durability is affected by material stiffness and fatigue resistance of electronic assemblies.

In addition to measuring whole PCB qualities, manufacturers also perform more detailed testing on PCB materials, such as the cured laminate and adhesive that hold wires in place and strengthen PCB structure. Since their cure is essential for end-use performance and reliability, manufacturers use thermal analysis to rapidly evaluate degree of cure and adjust their formulations. The degree of cure in thermosets can be determined through measuring the glass transition temperature (Tg) or a residual cure exotherm using differential scanning calorimetry (DSC). From small components to finished product, PCBs are improved at all stages by superior material characterization.

Material strength

- Young’s modulus, yield strength, ultimate strength, elongation at break

- Fatigue and durability, S-N curves

- Strength vs. temperature

Final assembly strength

- Bond or joint performance

- Flexural, bending or crush failure points

- Fatigue and durability, S-N curves

- Strength vs temperature

Differential Scanning Calorimetry (DSC)

- Glass Transition Temperature (Tg)

Temperature Range: -180°C to 725°C

Thermogravimetric Analysis (TGA)

- Decomposition Temperatures

- Compositional analysis

SA measures impact of humidity instead of temperature

- HAST test

- Water adsorption

Temperature Range: RT to 1500°C

- Thermal Management Properties

- Thermal Diffusivity

- Thermal Conductivity

- Heat Capacity

Temperature Range: -175°C to 2800°C

Thermomechanical Analysis (TMA)

- Composite or Laminate Material Compatibility

- Failure Analysis

- Glass transition temperature (Tg)

- Coefficient of Thermal Expansion (CTE)

- Softening Points

- Time to delamination

450 RH measures impact of humidity instead of temperature

- Composite or Laminate Material Compatibility

- Failure Analysis

- Swelling or shrinking

- Coefficient of Hygroscopic Expansion (CHE)

Temperature Range: -150°C to 1000°C

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

- Displays and Optics

-

Organic light emitting diodes (OLEDs) are thin films that emit light when an electric current is applied. OLEDs are used in a variety of everyday electronics including televisions, mobile phones, computer monitors, and display screens. Raw materials for OLED devices must be highly pure to extend the life of the luminescence and quality of the final product. Current research aims to develop OLED screens with brighter, clearer resolutions as well as white OLED solid-state lighting devices. Researchers turn to material science to detect impurities in their OLED materials and optimize their designs for enhanced performance in all end-use conditions.

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

- UV initiated cure time

- Modulus of cure

- Viscosity

- Tg of thin films (DMA)

Temperature Range: -150°C to 600°C

- 5G Materials

-

5G offers faster internet speeds, lower latency, and increased connectivity to industries ranging from infrastructure to consumer devices. Materials for 5G devices, including antennas, PCBs, cases, frames, semiconductors, EMCs, and microwave medium ceramics, must be tested and optimized for the final device’s end-use durability and functionality. Especially as researchers explore materials that reduce cost and enhance performance, they use TA Instruments material analysis solutions to assess:

- Dielectric Properties

- Stability

- Mechanical Properties

- Heat Dissipation

- Processability

- Processability (viscosity)

- Shear included dielectric measurements

Temperature Range: -150°C to 600°C

- Thermal Management Properties

- Thermal Diffusivity

- Thermal Conductivity

- Heat Capacity

Temperature Range: -175°C to 2800°C

Thermomechanical Analysis (TMA)

- Composite or Laminate Material Compatibility

- Failure Analysis

- Glass transition temperature (Tg)

- Coefficient of Thermal Expansion (CTE)

- Softening Points

- Time to delamination

450 RH measures impact of humidity instead of temperature

- Composite or Laminate Material Compatibility

- Failure Analysis

- Swelling or shrinking

- Coefficient of Hygroscopic Expansion (CHE)

Temperature Range: -150°C to 1000°C

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

Material strength

- Young’s modulus, yield strength, ultimate strength, elongation at break

- Fatigue and durability, S-N curves

- Strength vs. temperature

Final assembly strength

- Bond or joint performance

- Flexural, bending or crush failure points

- Fatigue and durability, S-N curves

- Strength vs temperature

- Energy Storage

-

Lithium-ion batteries power consumer electronics, from cell phones to medical devices, and are increasingly being used in electric vehicles and grid energy storage. Although they are already widely used, lithium-ion batteries still have room for improvement in performance, cost, and safety. Researchers are enhancing lithium-ion batteries by optimizing materials in the four main battery parts: the cathode, anode, separator, and electrolyte.

Waters / TA Instruments supports material characterization of lithium-ion batteries through thermal analysis, microcalorimetry, rheology, and mechanical test solutions tailored to battery development. Battery researchers, formulators, and production specialists turn to industry-leading material analysis instrumentation to develop better performing and safer batteries.

Dynamic Mechanical Analysis (DMA)

- Glass transition temperature (Tg)

- secondary transitions

Modulus

- viscoelasticity (storage modulus, loss modulus, tan delta)

- creep and creep compliance

- stress relaxation

- shrinkage and shrinkage forces

Characterization of mechanical anisotropy

Batch-to-batch material repeatability

Mechanical properties of materials

- Storage modulus

- Glass transition (Tg)

Temperature Range: -150°C to 600°C

Material strength

- Young’s modulus, yield strength, ultimate strength, elongation at break

- Fatigue and durability, S-N curves

- Strength vs. temperature

Final assembly strength

- Flexural, bending or crush failure points

- Fatigue and durability, S-N curves

- Strength vs temperature

- Thermal Management Properties

- Thermal Diffusivity

- Thermal Conductivity

- Heat Capacity

Temperature Range: -175°C to 2800°C

Resources

Webinars

Blogs

Application Notes

- A New Cyclic TMA Test Protocol for Evaluation of Electronic & Dielectric Materials

- Predicting Printed Circuit Board Delamination

- Characterization of Epoxy Prepregs by DSC

- Characterization of an Epoxy Resin Compound by MDSC®

- Characterization of Printed Circuit Board Materials by DMA

- Simultaneous Rheology – Dielectric Measurements of Epoxy Curing

- View all Application Notes