The DMA 850 offers your choice of two dedicated environmental systems: the Standard Furnace and the DMA-RH Accessory for humidity and temperature control. Installation is simple, making it convenient to switch between systems as required. All environmental systems and accessories are designed specifically for high performance DMA measurements and seamless integration and are manufactured by TA Instruments.

Standard Furnace

Standard Furnace

The Standard Furnace for the DMA850 is a wide-range bifilar wound furnace that provides uniform temperature control from -160°C to 600 °C. This field-proven design provides for efficient and precise temperature control over the entire temperature range in heating, cooling, and isothermal operation. For subambient temperature control, the furnace is used in combination with one of four available cooling accessories to meet your testing requirements. A high-sensitivity thermocouple is in close proximity to the sample to provide a representative measurement of sample temperature, regardless of the mode of deformation being employed.

| Temperature range | -160 to 600 ˚C |

| Heating Rate | 0.1 to 20 ˚C/min |

| Cooling Rate | 0.1 to 10 ˚C/min |

| Isothermal Stability | ± -.1 ˚C |

Gas Cooling Accessory

Gas Cooling Accessory

The Gas Cooling Accessory (GCA) extends the operating range of the DMA 850 to -150°C. The GCA uses cold nitrogen gas generated from controlled evaporation of liquid nitrogen. Automated filling of the GCA tank can be programmed to occur after the scan is complete.

The Gas Cooling Accessory (GCA) extends the operating range of the DMA 850 to -150°C. The GCA uses cold nitrogen gas generated from controlled evaporation of liquid nitrogen. Automated filling of the GCA tank can be programmed to occur after the scan is complete.

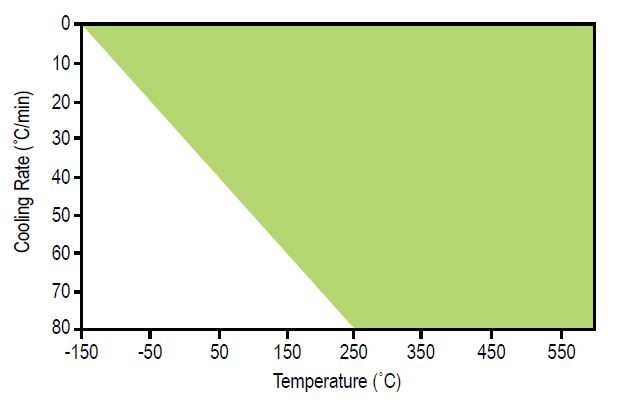

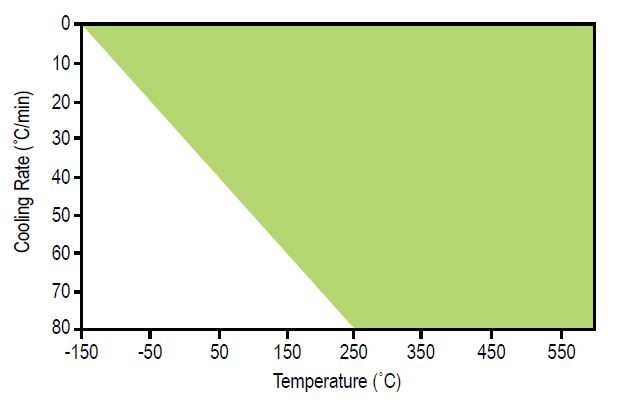

The GCA will provide ballistic or controlled cooling rates over the entire operating range of the DMA 850 (-150 to 600°C). In general, the maximum cooling rate is a function of the installed clamp and the thermal characteristics of the sample. The figure below shows the typical range* of controlled cooling rates available as a function of temperature.

*Actual performance may vary slightly depending on laboratory conditions and the clamping system installed.

Air Chiller Systems (ACS)

Air Chiller Systems (ACS)

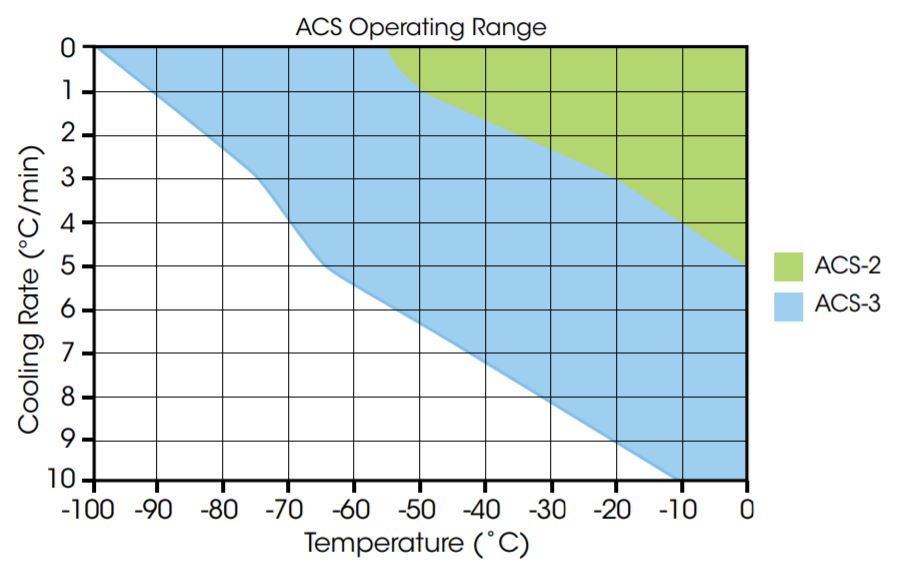

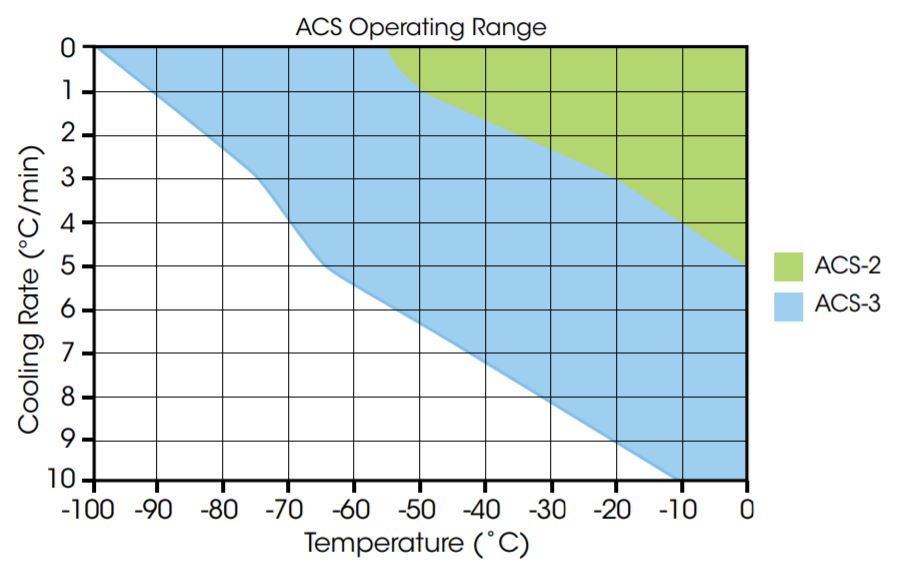

The new Air Chiller System models offer unique gas flow cooling systems that provide the capability for sub-ambient testing without the use of liquid nitrogen. Available in two models, the ACS-2 and ACS-3, the chillers feature a multi-stage cascading compressor design that employs compressed air (7 bar, 200 l/min) as the cooling medium. The ACS-2 and ACS-3 models permit operation of the DMA 850 with Standard Furnace at temperatures as low as -50 °C and -100 °C respectively *. The chiller systems can help eliminate or reduce liquid nitrogen usage and associated hazards from any laboratory and offer an incredible return on investment.

Nitrogen Purge Cooler

Nitrogen Purge Cooler

The Nitrogen Purge Cooler (NPC) is an innovative alternative for low temperature testing with the DMA 850. The NPC provides crash-cooling and controlled heating at temperatures as low as -160°C with all testing geometries. It is also an ideal choice for minimizing the cool-down time between consecutive experiments. A 2.5 L liquid-nitrogen filled dewar with heat exchanger cools nitrogen gas (2 bar to 8 bar, 30 L/min) before being fed to the DMA 850 Standard Furnace. The NPC is a small, economical, and effective option for laboratories that have basic cooling requirements.

The Nitrogen Purge Cooler (NPC) is an innovative alternative for low temperature testing with the DMA 850. The NPC provides crash-cooling and controlled heating at temperatures as low as -160°C with all testing geometries. It is also an ideal choice for minimizing the cool-down time between consecutive experiments. A 2.5 L liquid-nitrogen filled dewar with heat exchanger cools nitrogen gas (2 bar to 8 bar, 30 L/min) before being fed to the DMA 850 Standard Furnace. The NPC is a small, economical, and effective option for laboratories that have basic cooling requirements.

DMA-RH Accessory

DMA-RH Accessory

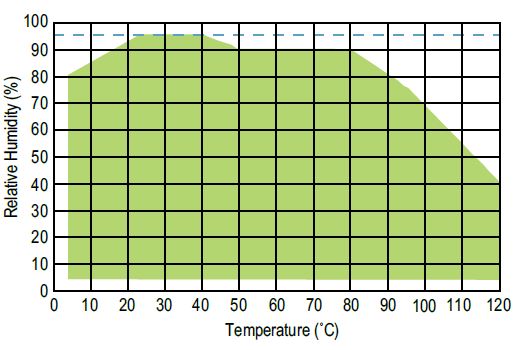

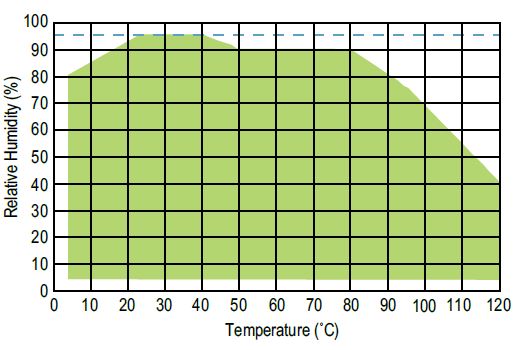

This precision environmental system provides accurate control of sample temperature and relative humidity for DMA experiments. A custom-designed humidity and temperature chamber optimized for mechanical measurements provides stable, reliable control of temperature and humidity over a wide range of operating conditions. The system successfully prevents condensation, a common occurrence in controlled-humidity environments which makes accurate control of relative humidity impossible. Stable, responsive peltier elements precisely control sample temperature while calibrated digital mass flow controllers deliver pre-heated gas of the prescribed ratio to achieve the target humidity.

The DMA-RH Accessory is a fully integrated unit and includes the following hardware components:

- The sample chamber mounts directly to the DMA. Peltier elements in the chamber precisely control the temperature to ±0.1°C. The sample chamber accommodates standard DMA clamps (tension, cantilever, and 3-point bending).

- A heated vapor-transfer line is maintained at a temperature above the dew point temperature of the humidified gas in order to avoid condensation and provide accurate results.

- The DMA-RH Accessory contains the humidifier and electronics which continuously monitor and control temperature and humidity of the sample chamber.

| Temperature range | 5 to 120 ˚C |

| Temperature Accuracy | ± 0.5 ˚C |

| Heating/Cooling Rate | Maximum ±1˚C/min |

| Humidity Range | See humidity range chart below |

| Humidity Accuracy | 5-90% RH: ±3% RH |

| >90% RH: ±5% RH | |

| Humidity Ramp Rate (both increasing and decreasing) |

2% RH/min (fixed) |

Humidity Range

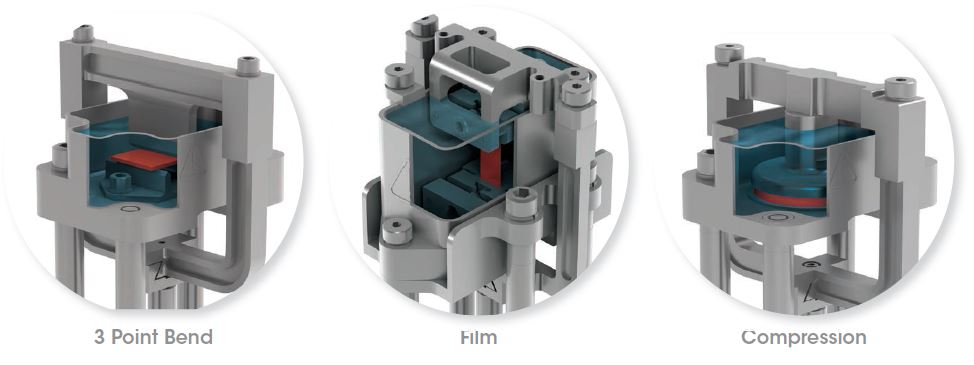

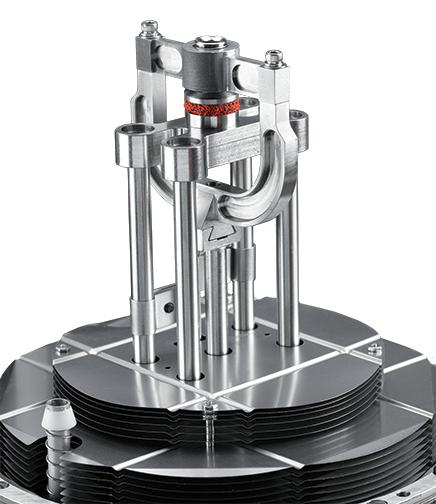

The DMA 850 features clamps in a complete set of deformation types, so a broad range of samples can be accurately analyzed and closely resemble real world process or application conditions. Each clamp is individually optimized for accuracy and ease-of-use.

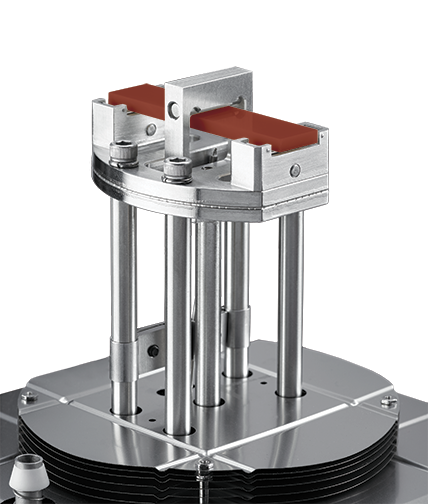

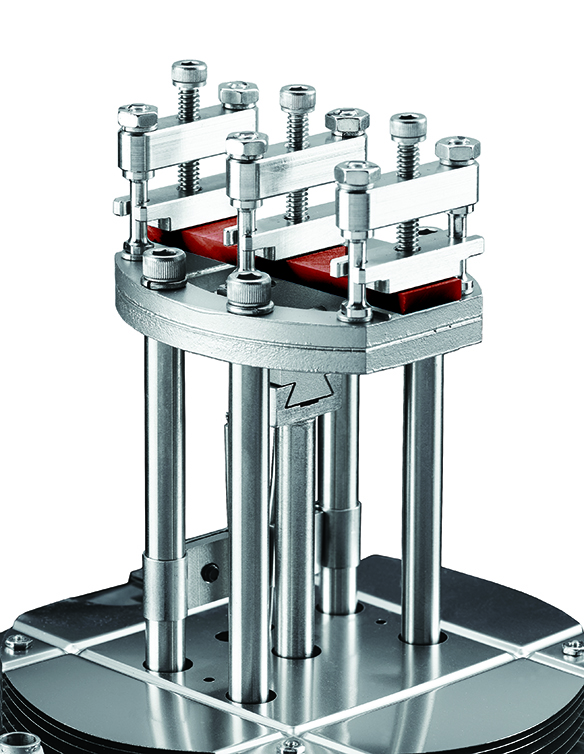

Dual/Single Cantilever

Dual/Single Cantilever

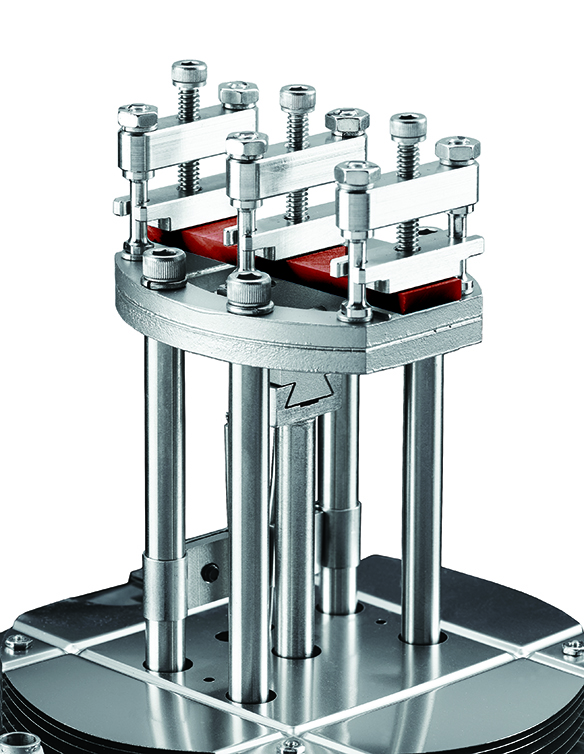

Cantilever (clamped) bending is a good general-purpose mode for evaluating thermoplastics and highly damped materials (e.g., elastomers). Available in sample lengths of 8 mm, 20 mm, and 35 mm, the cantilever clamps can be used in single or dual configurations. Dual cantilever is especially ideal for measuring the cure of supported thermosets.

Cantilever (clamped) bending is a good general-purpose mode for evaluating thermoplastics and highly damped materials (e.g., elastomers). Available in sample lengths of 8 mm, 20 mm, and 35 mm, the cantilever clamps can be used in single or dual configurations. Dual cantilever is especially ideal for measuring the cure of supported thermosets.

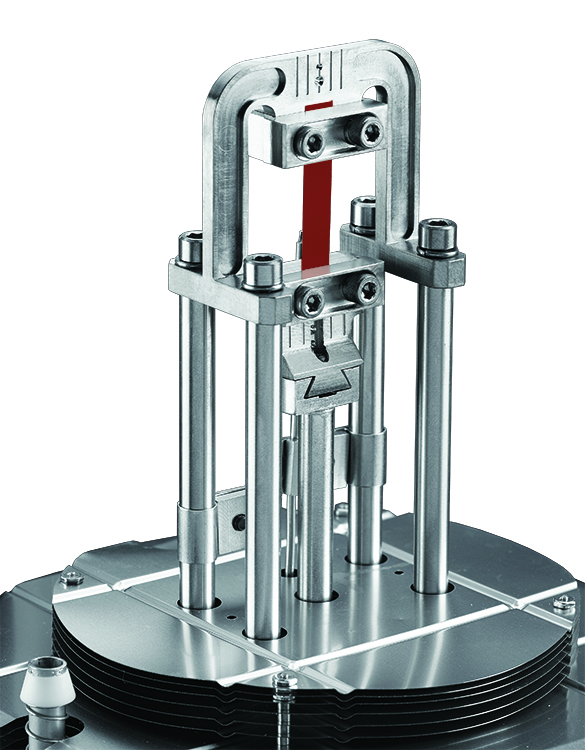

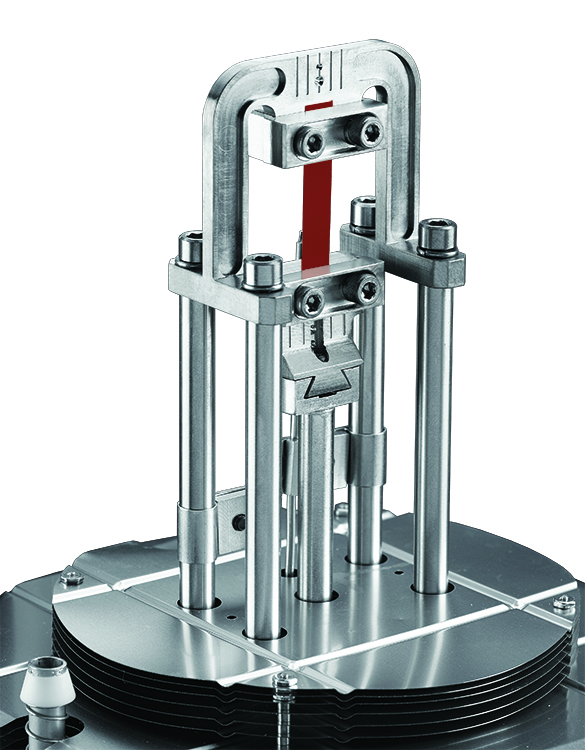

Tension

Tension

Tensile clamps are designed for uniaxial deformation of films and fibers. In oscillation experiments, the instrument uses constant and variable methods to apply a static load that prevents buckling and unnecessary creep. A newly designed film tension clamp simplifies the clamping mechanism to improve ease-of-use, clamping uniformity, and effectively prevents sample slippage. Visual guides aid in aligning film samples and integrated supports simplify fiber testing. The continuous travel of the DMA 850 makes sample loading in tension especially convenient.

Tensile clamps are designed for uniaxial deformation of films and fibers. In oscillation experiments, the instrument uses constant and variable methods to apply a static load that prevents buckling and unnecessary creep. A newly designed film tension clamp simplifies the clamping mechanism to improve ease-of-use, clamping uniformity, and effectively prevents sample slippage. Visual guides aid in aligning film samples and integrated supports simplify fiber testing. The continuous travel of the DMA 850 makes sample loading in tension especially convenient.

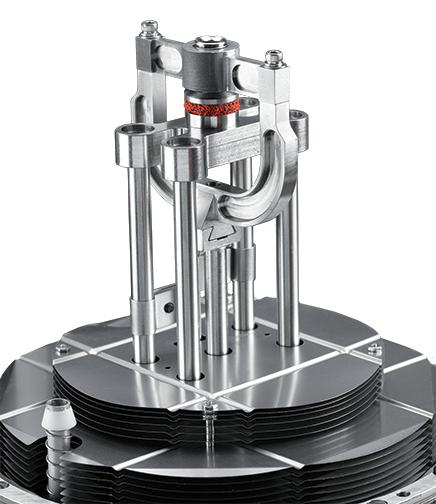

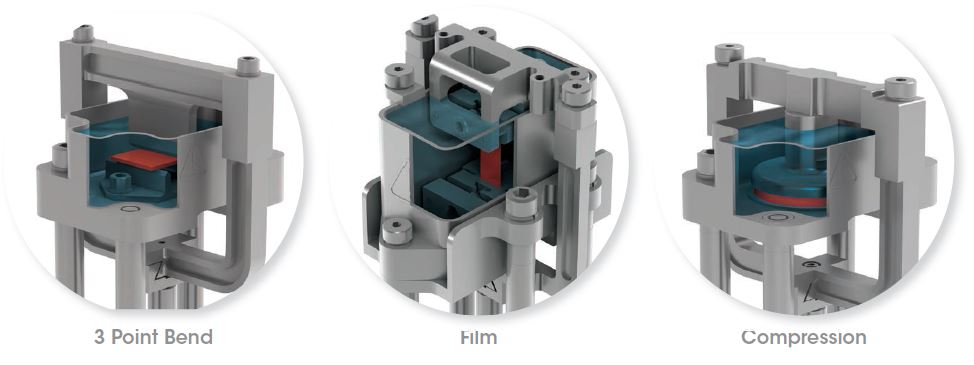

3-Point Bend

3-Point Bend

3-point bending, or free bending, is often considered a “pure” mode of deformation because clamping effects are eliminated. Sample spans of 5 mm, 10 mm, 15 mm, 20 mm, and 50 mm are available to accommodate a wide range of sample stiffness and specimen sizes. A unique low-friction, roller bearing supported design available on the 20 mm and 50 mm clamps improves modulus accuracy and reproducibility by accommodating and accounting for twist or curvature in the test specimen.

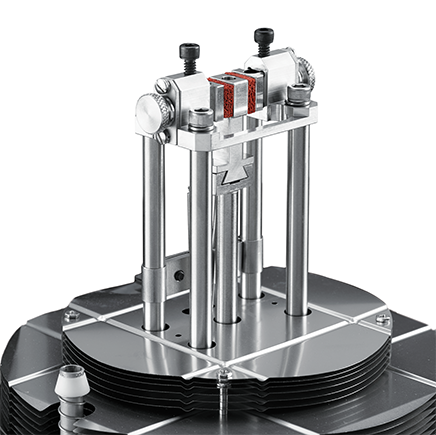

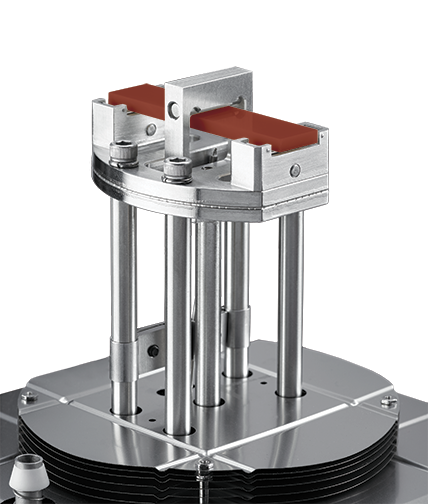

Shear Sandwich

Shear Sandwich

Two equal-size pieces of the same material are sheared between a fixed and moving plate for the measurement of shear modulus, G. This mode is ideal for soft materials such as gels, pressure sensitive adhesives, and high viscosity resins.

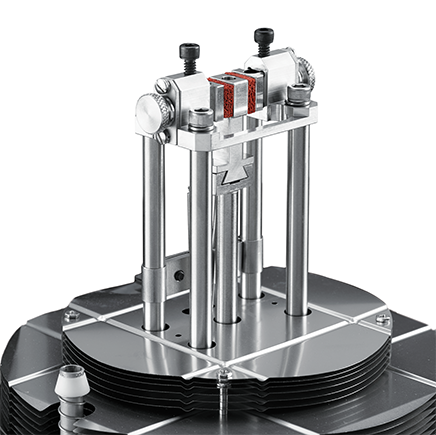

Compression

Compression

Parallel plate compression measurements are most suitable for low to moderate modulus materials such as foams and elastomers. It can also be used to measure expansion or contraction, tack testing for adhesives, compression set of rubber o-rings, and much more. A new self-aligning mechanism ensures the parallelism of upper and lower plates, enhancing strain and force uniformity while simplifying user interaction and improving modulus accuracy and precision.

Parallel plate compression measurements are most suitable for low to moderate modulus materials such as foams and elastomers. It can also be used to measure expansion or contraction, tack testing for adhesives, compression set of rubber o-rings, and much more. A new self-aligning mechanism ensures the parallelism of upper and lower plates, enhancing strain and force uniformity while simplifying user interaction and improving modulus accuracy and precision.

The standard compression kit includes parallel plates of 15 mm and 40 mm diameter, ideally designed for bulk measurements of moderate to low stiffness samples. The penetration kit is designed for higher stiffness materials and local measurements through the use of smaller probes: hemispherical, 1 mm penetration, or 6 mm plate.

Powder Clamp

Powder Clamp

The transition temperatures of loose powders can be difficult to measure by mechanical techniques. The powder accessory for the DMA850 is used with the dual cantilever clamp to observe transition temperatures of loose powdered materials by DMA, combining the enhanced sensitivity of mechanical analysis with the simple sample preparation of powder characterization techniques.

The transition temperatures of loose powders can be difficult to measure by mechanical techniques. The powder accessory for the DMA850 is used with the dual cantilever clamp to observe transition temperatures of loose powdered materials by DMA, combining the enhanced sensitivity of mechanical analysis with the simple sample preparation of powder characterization techniques.

Submersion

Submersion

Submersion clamps for the DMA 850 are designed specifically to provide the ideal test conditions for measuring mechanical properties in a fluid environment up to 150°C.

Submersion clamps for the DMA 850 are designed specifically to provide the ideal test conditions for measuring mechanical properties in a fluid environment up to 150°C.

- Accurate sample temperature is obtained by a thermocouple placed within the fluid reservoir and close to the sample

- Inert stainless steel construction and a seal-free design ensure compatibility with a wide range of fluids

- Temperature control provided by the Standard Furnace without additional circulators or environmental systems

Sample Sizes

Sample Sizes

| Deformation Modes | |

| Dual/Single Cantilever | 8/4* mm (L), Up to 15 mm (W) and 5 mm (T) |

| 20/10* mm (L), Up to 15 mm (W) and 5 mm (T) | |

| 35/17.5* mm (L), Up to 15 mm (W) and 5 mm (T) | |

| 3-Point Bend | 5,10, or 15 mm (L), Up to 15 mm (W) and 7 mm (T) |

| 20 mm (L), Up to 15 mm (W) and 7 mm (T) | |

| 50 mm (L), Up to 15 mm (W) and 7 mm (T) | |

| Tension | |

| Film/Fiber | 5 to 30 mm (L), Up to 8 mm (W) and 2 mm (T) |

| Fiber | 5 to 30 mm (L), 5 denier (0.57 tex) to 0.8 mm diameter |

| Shear | 10 mm square, Up to 4 mm (T) |

| Compression | 15 and 40 mm diameter, Up to 10 mm (T) |

| Submersion | |

| Tension | Fixed at 15 mm (L), Up to 8 mm (W) and 2 mm (T) |

| Compression | 25 mm diameter, Up to 10 mm (T) |

| 3-Point Bend | 5, 10, or 15 mm (L), Up to 15 mm (W) and 7 mm (T) |

- Accessories

-

The DMA 850 offers your choice of two dedicated environmental systems: the Standard Furnace and the DMA-RH Accessory for humidity and temperature control. Installation is simple, making it convenient to switch between systems as required. All environmental systems and accessories are designed specifically for high performance DMA measurements and seamless integration and are manufactured by TA Instruments.

Standard Furnace

Standard Furnace

The Standard Furnace for the DMA850 is a wide-range bifilar wound furnace that provides uniform temperature control from -160°C to 600 °C. This field-proven design provides for efficient and precise temperature control over the entire temperature range in heating, cooling, and isothermal operation. For subambient temperature control, the furnace is used in combination with one of four available cooling accessories to meet your testing requirements. A high-sensitivity thermocouple is in close proximity to the sample to provide a representative measurement of sample temperature, regardless of the mode of deformation being employed.

Temperature range -160 to 600 ˚C Heating Rate 0.1 to 20 ˚C/min Cooling Rate 0.1 to 10 ˚C/min Isothermal Stability ± -.1 ˚C Gas Cooling Accessory

Gas Cooling Accessory

The Gas Cooling Accessory (GCA) extends the operating range of the DMA 850 to -150°C. The GCA uses cold nitrogen gas generated from controlled evaporation of liquid nitrogen. Automated filling of the GCA tank can be programmed to occur after the scan is complete.

The Gas Cooling Accessory (GCA) extends the operating range of the DMA 850 to -150°C. The GCA uses cold nitrogen gas generated from controlled evaporation of liquid nitrogen. Automated filling of the GCA tank can be programmed to occur after the scan is complete.The GCA will provide ballistic or controlled cooling rates over the entire operating range of the DMA 850 (-150 to 600°C). In general, the maximum cooling rate is a function of the installed clamp and the thermal characteristics of the sample. The figure below shows the typical range* of controlled cooling rates available as a function of temperature.

*Actual performance may vary slightly depending on laboratory conditions and the clamping system installed.

Air Chiller Systems (ACS)

Air Chiller Systems (ACS)

The new Air Chiller System models offer unique gas flow cooling systems that provide the capability for sub-ambient testing without the use of liquid nitrogen. Available in two models, the ACS-2 and ACS-3, the chillers feature a multi-stage cascading compressor design that employs compressed air (7 bar, 200 l/min) as the cooling medium. The ACS-2 and ACS-3 models permit operation of the DMA 850 with Standard Furnace at temperatures as low as -50 °C and -100 °C respectively *. The chiller systems can help eliminate or reduce liquid nitrogen usage and associated hazards from any laboratory and offer an incredible return on investment.

Nitrogen Purge Cooler

Nitrogen Purge Cooler

The Nitrogen Purge Cooler (NPC) is an innovative alternative for low temperature testing with the DMA 850. The NPC provides crash-cooling and controlled heating at temperatures as low as -160°C with all testing geometries. It is also an ideal choice for minimizing the cool-down time between consecutive experiments. A 2.5 L liquid-nitrogen filled dewar with heat exchanger cools nitrogen gas (2 bar to 8 bar, 30 L/min) before being fed to the DMA 850 Standard Furnace. The NPC is a small, economical, and effective option for laboratories that have basic cooling requirements.

The Nitrogen Purge Cooler (NPC) is an innovative alternative for low temperature testing with the DMA 850. The NPC provides crash-cooling and controlled heating at temperatures as low as -160°C with all testing geometries. It is also an ideal choice for minimizing the cool-down time between consecutive experiments. A 2.5 L liquid-nitrogen filled dewar with heat exchanger cools nitrogen gas (2 bar to 8 bar, 30 L/min) before being fed to the DMA 850 Standard Furnace. The NPC is a small, economical, and effective option for laboratories that have basic cooling requirements.DMA-RH Accessory

DMA-RH Accessory

This precision environmental system provides accurate control of sample temperature and relative humidity for DMA experiments. A custom-designed humidity and temperature chamber optimized for mechanical measurements provides stable, reliable control of temperature and humidity over a wide range of operating conditions. The system successfully prevents condensation, a common occurrence in controlled-humidity environments which makes accurate control of relative humidity impossible. Stable, responsive peltier elements precisely control sample temperature while calibrated digital mass flow controllers deliver pre-heated gas of the prescribed ratio to achieve the target humidity.

The DMA-RH Accessory is a fully integrated unit and includes the following hardware components:

- The sample chamber mounts directly to the DMA. Peltier elements in the chamber precisely control the temperature to ±0.1°C. The sample chamber accommodates standard DMA clamps (tension, cantilever, and 3-point bending).

- A heated vapor-transfer line is maintained at a temperature above the dew point temperature of the humidified gas in order to avoid condensation and provide accurate results.

- The DMA-RH Accessory contains the humidifier and electronics which continuously monitor and control temperature and humidity of the sample chamber.

Temperature range 5 to 120 ˚C Temperature Accuracy ± 0.5 ˚C Heating/Cooling Rate Maximum ±1˚C/min Humidity Range See humidity range chart below Humidity Accuracy 5-90% RH: ±3% RH >90% RH: ±5% RH Humidity Ramp Rate

(both increasing and decreasing)2% RH/min (fixed) Humidity Range

- Clamps

-

The DMA 850 features clamps in a complete set of deformation types, so a broad range of samples can be accurately analyzed and closely resemble real world process or application conditions. Each clamp is individually optimized for accuracy and ease-of-use.

Dual/Single Cantilever

Dual/Single Cantilever

Cantilever (clamped) bending is a good general-purpose mode for evaluating thermoplastics and highly damped materials (e.g., elastomers). Available in sample lengths of 8 mm, 20 mm, and 35 mm, the cantilever clamps can be used in single or dual configurations. Dual cantilever is especially ideal for measuring the cure of supported thermosets.

Cantilever (clamped) bending is a good general-purpose mode for evaluating thermoplastics and highly damped materials (e.g., elastomers). Available in sample lengths of 8 mm, 20 mm, and 35 mm, the cantilever clamps can be used in single or dual configurations. Dual cantilever is especially ideal for measuring the cure of supported thermosets.

Tension

Tension

Tensile clamps are designed for uniaxial deformation of films and fibers. In oscillation experiments, the instrument uses constant and variable methods to apply a static load that prevents buckling and unnecessary creep. A newly designed film tension clamp simplifies the clamping mechanism to improve ease-of-use, clamping uniformity, and effectively prevents sample slippage. Visual guides aid in aligning film samples and integrated supports simplify fiber testing. The continuous travel of the DMA 850 makes sample loading in tension especially convenient.

Tensile clamps are designed for uniaxial deformation of films and fibers. In oscillation experiments, the instrument uses constant and variable methods to apply a static load that prevents buckling and unnecessary creep. A newly designed film tension clamp simplifies the clamping mechanism to improve ease-of-use, clamping uniformity, and effectively prevents sample slippage. Visual guides aid in aligning film samples and integrated supports simplify fiber testing. The continuous travel of the DMA 850 makes sample loading in tension especially convenient.

3-Point Bend

3-Point Bend

3-point bending, or free bending, is often considered a “pure” mode of deformation because clamping effects are eliminated. Sample spans of 5 mm, 10 mm, 15 mm, 20 mm, and 50 mm are available to accommodate a wide range of sample stiffness and specimen sizes. A unique low-friction, roller bearing supported design available on the 20 mm and 50 mm clamps improves modulus accuracy and reproducibility by accommodating and accounting for twist or curvature in the test specimen.

Shear Sandwich

Shear Sandwich

Two equal-size pieces of the same material are sheared between a fixed and moving plate for the measurement of shear modulus, G. This mode is ideal for soft materials such as gels, pressure sensitive adhesives, and high viscosity resins.

Compression

Compression

Parallel plate compression measurements are most suitable for low to moderate modulus materials such as foams and elastomers. It can also be used to measure expansion or contraction, tack testing for adhesives, compression set of rubber o-rings, and much more. A new self-aligning mechanism ensures the parallelism of upper and lower plates, enhancing strain and force uniformity while simplifying user interaction and improving modulus accuracy and precision.

Parallel plate compression measurements are most suitable for low to moderate modulus materials such as foams and elastomers. It can also be used to measure expansion or contraction, tack testing for adhesives, compression set of rubber o-rings, and much more. A new self-aligning mechanism ensures the parallelism of upper and lower plates, enhancing strain and force uniformity while simplifying user interaction and improving modulus accuracy and precision.The standard compression kit includes parallel plates of 15 mm and 40 mm diameter, ideally designed for bulk measurements of moderate to low stiffness samples. The penetration kit is designed for higher stiffness materials and local measurements through the use of smaller probes: hemispherical, 1 mm penetration, or 6 mm plate.

Powder Clamp

Powder Clamp

The transition temperatures of loose powders can be difficult to measure by mechanical techniques. The powder accessory for the DMA850 is used with the dual cantilever clamp to observe transition temperatures of loose powdered materials by DMA, combining the enhanced sensitivity of mechanical analysis with the simple sample preparation of powder characterization techniques.

The transition temperatures of loose powders can be difficult to measure by mechanical techniques. The powder accessory for the DMA850 is used with the dual cantilever clamp to observe transition temperatures of loose powdered materials by DMA, combining the enhanced sensitivity of mechanical analysis with the simple sample preparation of powder characterization techniques.Submersion

Submersion

Submersion clamps for the DMA 850 are designed specifically to provide the ideal test conditions for measuring mechanical properties in a fluid environment up to 150°C.

Submersion clamps for the DMA 850 are designed specifically to provide the ideal test conditions for measuring mechanical properties in a fluid environment up to 150°C.- Accurate sample temperature is obtained by a thermocouple placed within the fluid reservoir and close to the sample

- Inert stainless steel construction and a seal-free design ensure compatibility with a wide range of fluids

- Temperature control provided by the Standard Furnace without additional circulators or environmental systems

Sample Sizes

Sample Sizes

Deformation Modes Dual/Single Cantilever 8/4* mm (L), Up to 15 mm (W) and 5 mm (T) 20/10* mm (L), Up to 15 mm (W) and 5 mm (T) 35/17.5* mm (L), Up to 15 mm (W) and 5 mm (T) 3-Point Bend 5,10, or 15 mm (L), Up to 15 mm (W) and 7 mm (T) 20 mm (L), Up to 15 mm (W) and 7 mm (T) 50 mm (L), Up to 15 mm (W) and 7 mm (T) Tension Film/Fiber 5 to 30 mm (L), Up to 8 mm (W) and 2 mm (T) Fiber 5 to 30 mm (L), 5 denier (0.57 tex) to 0.8 mm diameter Shear 10 mm square, Up to 4 mm (T) Compression 15 and 40 mm diameter, Up to 10 mm (T) Submersion Tension Fixed at 15 mm (L), Up to 8 mm (W) and 2 mm (T) Compression 25 mm diameter, Up to 10 mm (T) 3-Point Bend 5, 10, or 15 mm (L), Up to 15 mm (W) and 7 mm (T)