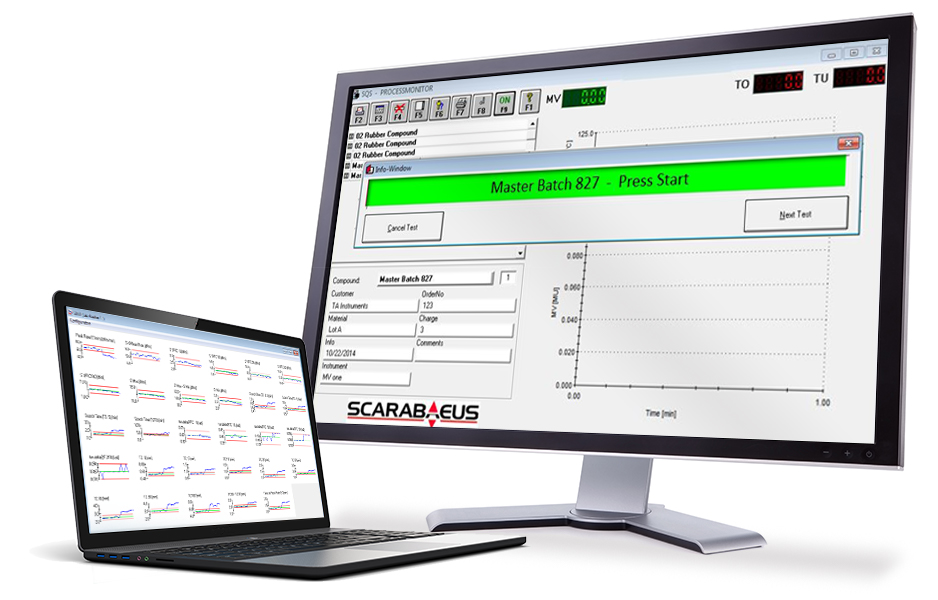

Scarabaeus Software

Powerful software designed to meet the needs of the rubber industry, from the R&D lab to the production floor.

Scarabaeus software is a powerful and versatile system for programming experiments, generating rapid results, and managing data from all rubber testing instruments.

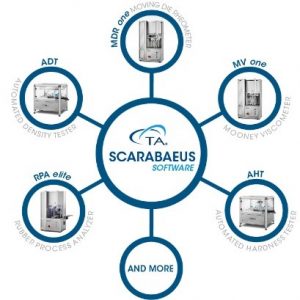

Designed for integration, the Scarabaeus software system unites data from RPA, MDR, Mooney Viscometer, Hardness and Density testing. Results can be organized, compared and analyzed by compound, batch number, date and more. Advanced integration with even greater capability is also available.