Descripción general

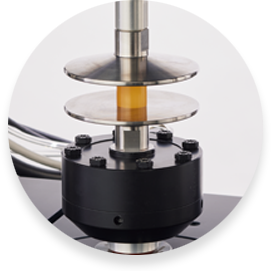

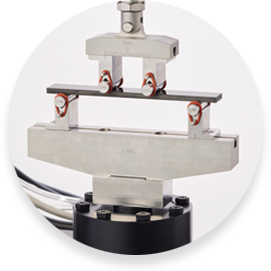

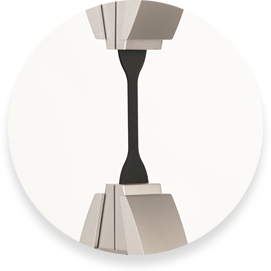

Las abrazaderas de tensión y compresión de titanio ElectroForce de TA Instruments se caracterizan por su baja masa y son adecuadas para una amplia gama de aplicaciones, incluyendo materiales de ingeniería, biomateriales y pruebas con tejidos.

En este modo, la muestra se sujeta por la parte superior e inferior y se coloca en tensión o se prueba “a través de cero” para la carga de fatiga con tensión inversa. Hay disponibles varias abrazaderas de tensión, incluyendo una mordaza de cuña autoalineable y versátil y una mordaza de tornillo de banco sumergible con caras intercambiables.

Características clave

- Construcción de titanio

- Puede usarse tanto en aplicaciones sumergibles como no sumergibles

- Diseño resistente a la corrosión

- Rosca de montaje 10-32 UNF

- Capacidad de fuerza de 450 N

- Peso total estimado: 79 gramos cada una

- Diseño de abrazadera con tuercas hexagonales para bloqueo

- Caras de agarre intercambiables

- Caras de agarre moleteadas planas y en V disponibles

- Para usar en diversos sistemas de prueba ElectroForce

- Rango de funcionamiento: de -150 °C a 350 °C