Ensuring Patient Safety with Medical Device Testing

Medical devices play a significant role in the quality of health and well-being of patients globally. From adhesive bandages to heart valves, medical devices are used in the diagnosis, prevention, monitoring, and treatment of a broad range of medical conditions. Since these devices have many interactions with patients’ bodies and activities, medical device manufacturers must confirm that their respective products are built to operate with exceptional performance and reliability.

Improving the quality of life for those with chronic diseases like cancer and diabetes, as well as our aging population, has increased demand for high-performance medical devices while adhering to key regulations. As you work to develop novel medical devices, use TA Instruments to optimize and validate product performance and safety.

Analytical Testing for Medical Device Development Pathway

Before complete medical devices are implanted into patients, the development path from product idea to the final device is far from quick and easy.

The medical device development pathway – benchmarking native tissues, characterizing biomaterials and device materials, measuring the reliability of device subcomponents, and testing the efficacy and durability of complete devices – requires testing rigor enabled by precise and reliable instruments. Developing high-performing medical devices depends on the quality of your lab and measurements.

Explore each category in the medical device development pathway for more information.

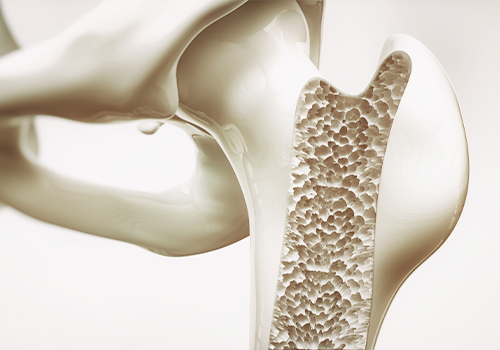

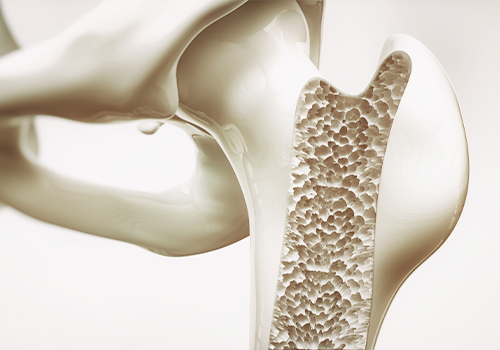

Characterizing Native Tissue

Investigating the behaviors of native tissues offers insights into natural or diseased tissue performance, allowing device developers to explore how these qualities translate into medical device functions. Similarly, techniques for tissue characterization can be leveraged for engineered tissue.

Many tissue-engineered medical products (TEMPs) can be assessed for properties such as mechanical stiffness, compliance, strength, or stability using the same instruments used for native tissue.

Investigate tissue behaviors to develop high-performing medical devices with TA Instruments solutions.

- Cartilage, Tendons (of animal models), Ligaments (of animal models)

- Strength

- Stiffness

- Durability

- In Vivo Loading

- Cartilage, Bone, Dentin/Teeth

- Strength

- Stiffness

- Durability

- Spinal Cord and Nerves

- Strength

- Stiffness

- Response to injury

- Muscle

- Strength

- Stiffness

- Response to Stimulus

- Bone, Dentin/Teeth

- Strength

- Stiffness

- Durability

- Bone, Tendon, Ligament

- Strength

- Stiffness

- Durability

- Heart valve leaflets, Pericardium

- Strength

- Stiffness

- Durability

- Anisotropy

- Skin

- Strength

- Stiffness

- Anisotropy

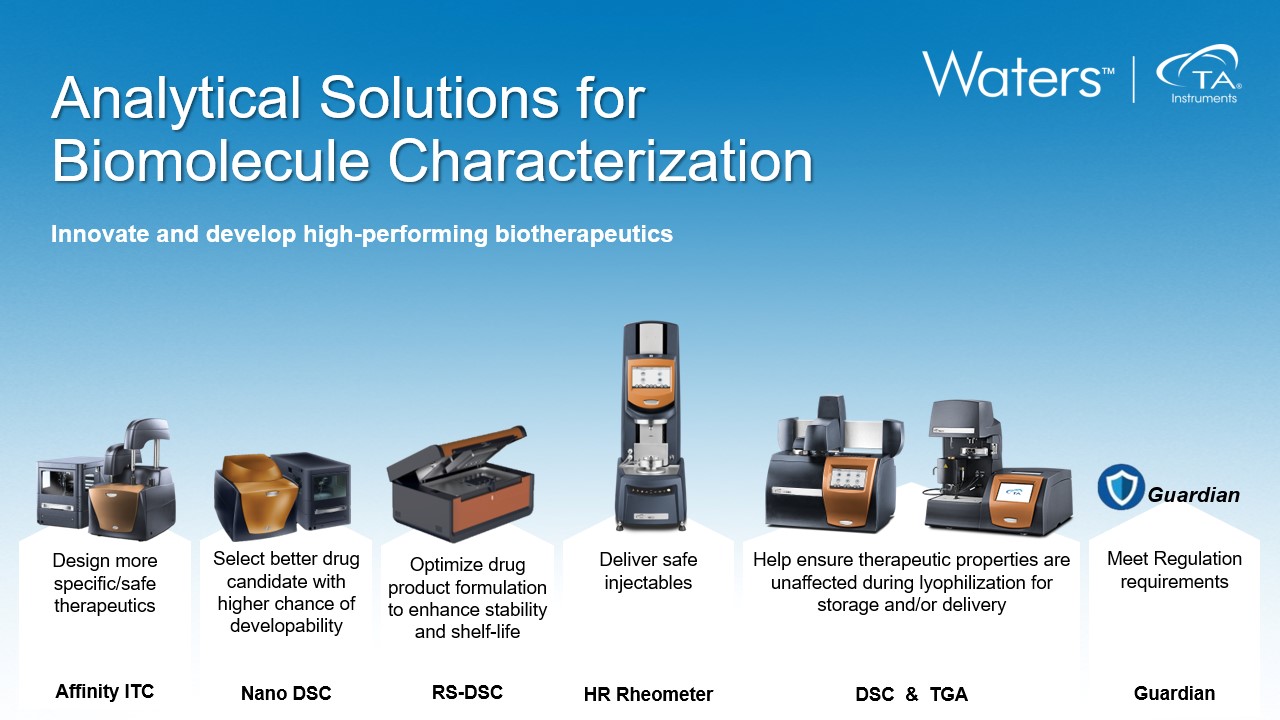

Characterizing Biomaterials and Device Materials

A biomaterial is any synthetic material used in the replacement or restoration of body tissue functions. Since biomaterials and other device materials are used in developing medical devices, it is essential to understand how biomaterials and other components contribute to final medical device functions. Most materials used for medical device construction are classified under metals, ceramics, polymers, and composites.

Investigate material properties relevant to medical device construction with TA Instruments solutions.

- Polymers

- Volatiles

- Thermal and Oxidative Stability

- Kinetics

- Lifetime Prediction

- Composition Information

- Residue

- Hydrogels

- Stiffness

- Modulus

- Creep-Recovery

- Contact Lens

- Lubrication

- Shape Memory Alloys (SMA)

- Thermal Cycling for Transitions

- Polymers

- Glass Transition

- Effect of Plasticization

- Effect of Humidity

- Mechanical Properties

- Thermal Cycling

- Hydrogels

- Creep-Recovery

- Polymers

- Glass Transition

- Coefficient of Thermal Expansion (CTE)

- Curing

- Effect of Plasticization

- Nickel-Titanium Super-elastic Materials

- Fatigue-to-Fracture

- S-N Curves

- Fatigue Life Curves

- Other High Purity Metal Stent Wire

- Fatigue-to-Fracture of Z-Shape Samples

- Bone Cement

- Fatigue and Durability

Differential Scanning Calorimetry

- Polymers

- Glass Transition

- Amorphous content

- Curing

- Cure reactions

- Effect of Plasticization

- Enthalpic Recovery/Aging

- Melting

- Degree of crystallinity

- Crystalline morphology

- Crystallization

- Solid Phase Changes

- Shape Memory Alloys (SMAs)

- Transition temperatures

- Adhesives

- Temperature ramp tests

- Axial or Tack Testing

- Shrinkage

- UV curing

- Hydrogels

- Gel time

- Gel strength

- Isothermal and non-isothermal gelation

- Creep-Recovery

Fatigue Tests of Device Subcomponents

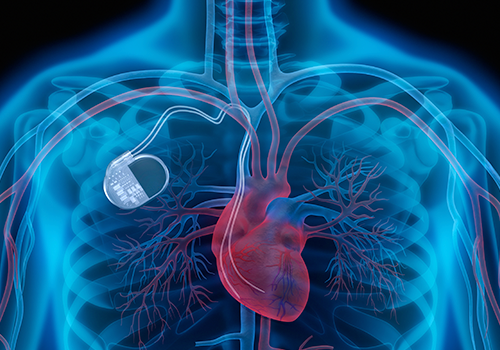

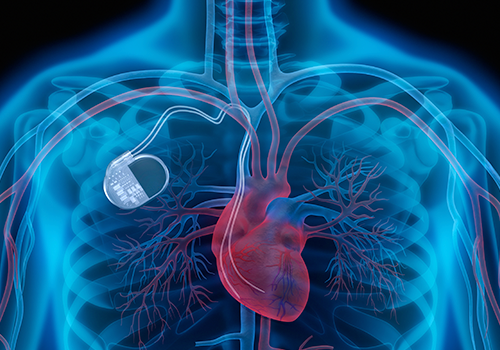

Each subcomponent used for medical device manufacturing comes with various properties that contribute to the success of the complete device. Understanding how the characteristics of each subcomponent can affect the performance and overall reliability of the complete device is very important to the final stage of the medical device development pathway. Furthermore, subcomponent failure analysis and testing are becoming an increasingly beneficial and requested element of regulatory submissions. Examples of device subcomponents are diamonds and frames, bone screws, dental screws, pacemaker leads, and many more.

Investigate fatigue properties of your medical device subcomponents with TA Instruments solutions

- Stent subsections (diamond surrogates)

- Fatigue-to-Fracture

- Fatigue Test-to-Success

- Pacemaker and Defibrillator Leads

- Fatigue-to-Fracture

- Fatigue Test-to-Success

- IVC Filters

- Fatigue-to-Fracture

- Pacemaker Cans and Connectors

- Fatigue and Durability

- Connector Reliability

- Bone Screws

- Strength

- Insertion Torque

- Pull-out Strength

- Dental Screws

- Strength

- Insertion Torque

- Pull-out Strength

- Orthopedic Device Connections

- Strength

- Durability

- Dental Crowns

- Wear properties

- Stents of Transcatheter Heart Valves (TAVR)

- Pulsatile durability

- Fatigue-to-Fracture

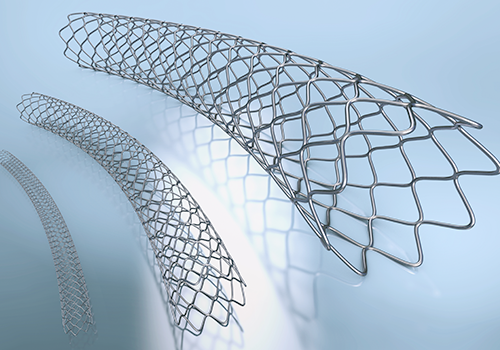

Fatigue Tests of Complete Devices

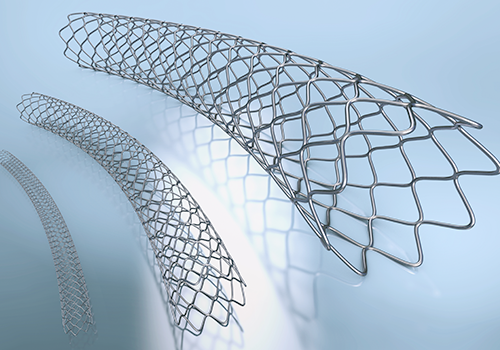

Testing complete devices verifies reliability and performance based on the end-use application. Ensuring that the final product meets specifications with utmost performance without compromising patient safety is critical to the success of the overall product development and regulatory submissions. ASTM and ISO standards include exact measurements of complete device behaviors, which can be measured on-the-bench with TA Instruments. Examples of complete devices are heart valves, stent/grafts, contact lenses, dental implants, spinal implants, and many more.

Investigate fatigue properties of your complete medical device with TA Instruments solutions

- Contact lenses

- Friction

- Lubricity

- Transcatheter Heart Valves (TAVR)

- Accelerated Wear Test (AWT)

- Surgical Heart Valves

- Accelerated Wear Test (AWT)

- Dental Implant

- Axial Fatigue

- Spinal Implant

- Axial Fatigue

- Axial-Torsion Fatigue

- Hip Implants

- Axial Fatigue

- Axial-Torsion Fatigue

- Breast Implant

- Axial Fatigue

- IVC Filters

- Axial-Radial Durability

- Other cardiovascular devices

- Axial Durability

- Stent or Stent/Grafts

- Pulsatile durability

- Fatigue-to-Fracture

- IVC Filters

- Radial durability

- Native Tissue

-

Characterizing Native Tissue

Investigating the behaviors of native tissues offers insights into natural or diseased tissue performance, allowing device developers to explore how these qualities translate into medical device functions. Similarly, techniques for tissue characterization can be leveraged for engineered tissue.

Many tissue-engineered medical products (TEMPs) can be assessed for properties such as mechanical stiffness, compliance, strength, or stability using the same instruments used for native tissue.

Investigate tissue behaviors to develop high-performing medical devices with TA Instruments solutions.

- Cartilage, Tendons (of animal models), Ligaments (of animal models)

- Strength

- Stiffness

- Durability

- In Vivo Loading

- Cartilage, Bone, Dentin/Teeth

- Strength

- Stiffness

- Durability

- Spinal Cord and Nerves

- Strength

- Stiffness

- Response to injury

- Muscle

- Strength

- Stiffness

- Response to Stimulus

- Bone, Dentin/Teeth

- Strength

- Stiffness

- Durability

- Bone, Tendon, Ligament

- Strength

- Stiffness

- Durability

- Heart valve leaflets, Pericardium

- Strength

- Stiffness

- Durability

- Anisotropy

- Skin

- Strength

- Stiffness

- Anisotropy

- Cartilage, Tendons (of animal models), Ligaments (of animal models)

- Biomaterials

-

Characterizing Biomaterials and Device Materials

A biomaterial is any synthetic material used in the replacement or restoration of body tissue functions. Since biomaterials and other device materials are used in developing medical devices, it is essential to understand how biomaterials and other components contribute to final medical device functions. Most materials used for medical device construction are classified under metals, ceramics, polymers, and composites.

Investigate material properties relevant to medical device construction with TA Instruments solutions.

- Polymers

- Volatiles

- Thermal and Oxidative Stability

- Kinetics

- Lifetime Prediction

- Composition Information

- Residue

- Hydrogels

- Stiffness

- Modulus

- Creep-Recovery

- Contact Lens

- Lubrication

- Shape Memory Alloys (SMA)

- Thermal Cycling for Transitions

- Polymers

- Glass Transition

- Effect of Plasticization

- Effect of Humidity

- Mechanical Properties

- Thermal Cycling

- Hydrogels

- Creep-Recovery

- Polymers

- Glass Transition

- Coefficient of Thermal Expansion (CTE)

- Curing

- Effect of Plasticization

- Nickel-Titanium Super-elastic Materials

- Fatigue-to-Fracture

- S-N Curves

- Fatigue Life Curves

- Other High Purity Metal Stent Wire

- Fatigue-to-Fracture of Z-Shape Samples

- Bone Cement

- Fatigue and Durability

Differential Scanning Calorimetry

- Polymers

- Glass Transition

- Amorphous content

- Curing

- Cure reactions

- Effect of Plasticization

- Enthalpic Recovery/Aging

- Melting

- Degree of crystallinity

- Crystalline morphology

- Crystallization

- Solid Phase Changes

- Shape Memory Alloys (SMAs)

- Transition temperatures

- Adhesives

- Temperature ramp tests

- Axial or Tack Testing

- Shrinkage

- UV curing

- Hydrogels

- Gel time

- Gel strength

- Isothermal and non-isothermal gelation

- Creep-Recovery

- Polymers

- Subcomponents

-

Fatigue Tests of Device Subcomponents

Each subcomponent used for medical device manufacturing comes with various properties that contribute to the success of the complete device. Understanding how the characteristics of each subcomponent can affect the performance and overall reliability of the complete device is very important to the final stage of the medical device development pathway. Furthermore, subcomponent failure analysis and testing are becoming an increasingly beneficial and requested element of regulatory submissions. Examples of device subcomponents are diamonds and frames, bone screws, dental screws, pacemaker leads, and many more.

Investigate fatigue properties of your medical device subcomponents with TA Instruments solutions

- Stent subsections (diamond surrogates)

- Fatigue-to-Fracture

- Fatigue Test-to-Success

- Pacemaker and Defibrillator Leads

- Fatigue-to-Fracture

- Fatigue Test-to-Success

- IVC Filters

- Fatigue-to-Fracture

- Pacemaker Cans and Connectors

- Fatigue and Durability

- Connector Reliability

- Bone Screws

- Strength

- Insertion Torque

- Pull-out Strength

- Dental Screws

- Strength

- Insertion Torque

- Pull-out Strength

- Orthopedic Device Connections

- Strength

- Durability

- Dental Crowns

- Wear properties

- Stents of Transcatheter Heart Valves (TAVR)

- Pulsatile durability

- Fatigue-to-Fracture

- Stent subsections (diamond surrogates)

- Complete Devices

-

Fatigue Tests of Complete Devices

Testing complete devices verifies reliability and performance based on the end-use application. Ensuring that the final product meets specifications with utmost performance without compromising patient safety is critical to the success of the overall product development and regulatory submissions. ASTM and ISO standards include exact measurements of complete device behaviors, which can be measured on-the-bench with TA Instruments. Examples of complete devices are heart valves, stent/grafts, contact lenses, dental implants, spinal implants, and many more.

Investigate fatigue properties of your complete medical device with TA Instruments solutions

- Contact lenses

- Friction

- Lubricity

- Transcatheter Heart Valves (TAVR)

- Accelerated Wear Test (AWT)

- Surgical Heart Valves

- Accelerated Wear Test (AWT)

- Dental Implant

- Axial Fatigue

- Spinal Implant

- Axial Fatigue

- Axial-Torsion Fatigue

- Hip Implants

- Axial Fatigue

- Axial-Torsion Fatigue

- Breast Implant

- Axial Fatigue

- IVC Filters

- Axial-Radial Durability

- Other cardiovascular devices

- Axial Durability

- Stent or Stent/Grafts

- Pulsatile durability

- Fatigue-to-Fracture

- IVC Filters

- Radial durability

- Contact lenses

Commonly Used Testing Standards

- ASTM E794 Test Method for Melting and Crystallization Temperatures by Thermal Analysis

- ASTM E1356 Test Method for the Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry

- ASTM E1641 Test Method for Decomposition Kinetics by Thermogravimetry Using the Flynn/Wall/Ozawa Method

- ASTM E2550 Test Method for Thermal Stability by Thermogravimetry

- ASTM D5023 Standard Test Method for Plastics: Dynamic Mechanical Properties: In Flexure (Three-Point Bending)

- ASTM E831 Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

- ASTM D5279 Standard Test Method for Plastics: Dynamic Mechanical Properties: In Torsion

- ISO 14801 Dentistry — Implants — Dynamic loading test for endosseous dental implants

- ASTM F3211 Standard Guide for Fatigue-to-Fracture (FtF) Methodology for Cardiovascular Medical Devices

- ASTM F2477 Pulsatile stent testing: Standard Test Methods for in vitro Pulsatile Durability Testing of Vascular Stents

Don’t see what you’re looking for? Click here to explore a comprehensive list of ASTM/ISO standards for your material testing needs.

Medical Device Resources

Medical Device Webinars

Medical Device Blogs

Medical Device Application Notes

- Determining the Mechanical Properties of Non-Woven PLGA Scaffolds

- Micromechanical Multicyclic Creep Tests of Human Cortical Bone

- Rheological Analysis of Hydrogel Materials

- Characterizing Hydrogels using Dynamic Mechanical Analysis Methods

- Measuring the Strength of Breast Implants

- Testing to Improve the Durability of Artificial Heart Valves

- Compressive Force Characterization of Inferior Vena Cava Filters

- View all application notes