Evolved Gas Analysis

Evolved Gas Analysis

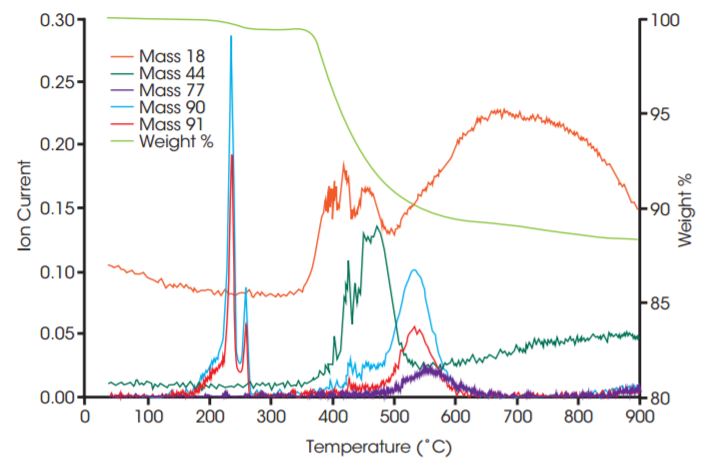

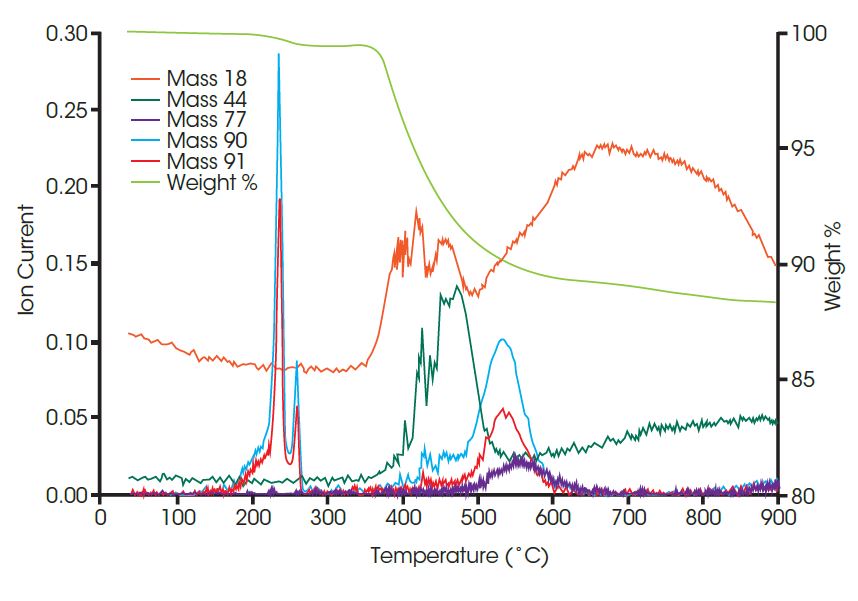

Evolved gas analysis involves the qualitative investigation of the evolved gas products from an SDT or TGA experiment. These products are generally the result of decomposition, but can also evolve from desorption, evaporation or chemical reactions. Evolved gas analysis is typically performed by interfacing a mass spectrometer (MS) or Fourier transform infrared spectrometer (FTIR) to the exit port of the furnace. Through the use of a heated transfer line, the evolved gas stream is delivered to the MS or FTIR instrument, and the compositional analysis is performed in real time. TA Instruments offers a 300 amu bench-top, quadrapole mass spectrometer with a heated capillary interface, with an instrument specific interface kit. A variety of FTIR suppliers provide gas cells and interfaces.

Evolved gas analysis involves the qualitative investigation of the evolved gas products from an SDT or TGA experiment. These products are generally the result of decomposition, but can also evolve from desorption, evaporation or chemical reactions. Evolved gas analysis is typically performed by interfacing a mass spectrometer (MS) or Fourier transform infrared spectrometer (FTIR) to the exit port of the furnace. Through the use of a heated transfer line, the evolved gas stream is delivered to the MS or FTIR instrument, and the compositional analysis is performed in real time. TA Instruments offers a 300 amu bench-top, quadrapole mass spectrometer with a heated capillary interface, with an instrument specific interface kit. A variety of FTIR suppliers provide gas cells and interfaces.

The Discovery SDT is the ideal platform for evolved gas analysis studies. A horizontal purge stream over the sample and a short path to the exit port eliminates dead volume in the furnace, thereby reducing product dilution and optimizing EGA sensitivity.

TA Instruments TRIOS software supports the importation of MS (trend analysis) and FTIR data (Gram-Schmidt and Chemigram reconstructions), allowing DSC/TGA and EGA data to be displayed on a common axis of temperature and/or time.

EGA Features and Benefits:

- Identification of decomposition products.

- Additional information for the interpretation of the reactions during DSC/TGA scans.

- Exact control of the furnace atmosphere before and during experiments.

Design Features and Benefits of the Discovery SDT for EGA Analysis:

- Horizontal purge stream over the sample for optimal sensitivity.

- Low volume furnace to eliminate dead volume, reducing dilution.

- Powerful TRIOS software allows importation of MS or FTIR data for improved data interpretation.

Mass Spectrometer

Mass Spectrometer

The Pfeiffer ThermoStarMS® is a benchtop quadrupole mass spectrometer, designed and optimized for evolved gas analysis. It features industry-standard technology configured for the efficient transfer, and rapid detection of offgas from the TGA furnace. Parts per billion (ppb) sensitivity is ensured with a state-of-the-art quadrupole detection system, including a cross-beam ion source, a single mass filter and a dual (Faraday and Secondary Electron Multiplier) detector system. This analyzer configuration is selected to optimize sensitivity and long-term stability performance.

Control of the experimental parameters and analysis of the mass spectral data is achieved through a user-friendly, recipe-driven software interface. Data collection can be triggered directly from the TGA software, and the resulting MS data can be combined with the corresponding TGA results for direct overlaying and comparison.

| Parameter | Performance |

| Mass range | 1-300 amu |

| Mass Resolution | 0.5 amu |

| Sensitivity | < 100 ppb (gas-dependent) |

| Ionization Source | Electron Ionization |

| Detector System | Dual (Faraday and Second Electron Multiplier) |

| Sample Pressure | 1 atm (nominal) |

| Bar Graph and Multiple Ion Detection | Bar graph and Peak Jump |

| Scanning Speed | |

| Bar graph Mode | 500 amu/s |

| Multiple Ion Detection | 500 channels/s |

| Transfer Line Temperature | 200°C |

| Transfer line | 2.0 meters, flexible |

| Filaments | Dual, customer changeable |

| Capillary | Quartz, changeable |

| Capillary size | I.D. = 0.15 mm |

| Inputs | Data collection controlled by TGA Trigger |

Blending Gas Delivery Module (GDM)

Blending Gas Delivery Module (GDM)

The Blending Gas Delivery Module (GDM) delivers flexibility in gas handling on the Discovery SDT 650. The GDM is an external accessory with two additional gas inlet ports that connect to the reactive gas port on the TGA. The GDM used in conjunction with the SDT 650 allows for automated switching between the gas ports, as well as software-controlled blending of binary mixtures of gases. The added capability to perform controlled blending of binary gas mixtures allows for TGA experiments to be carried out in an atmosphere where the concentration of gases may be in a fixed ratio, stepped incrementally or ramped at a controlled rate. The GDM is compatible with Nitrogen, Argon, Helium, Air, Oxygen, Carbon Dioxide, Carbon Monoxide and Forming Gas (4%H2/96% N2). This accessory can be used to study sorption of gasses onto a material at atmospheric pressure, Redox reactions, and thermal stability of materials in a controlled atmosphere.