<< View all Thermogravimetric Analyzers | Thermal Instruments Accessories

Mass Spectrometer

Mass Spectrometer

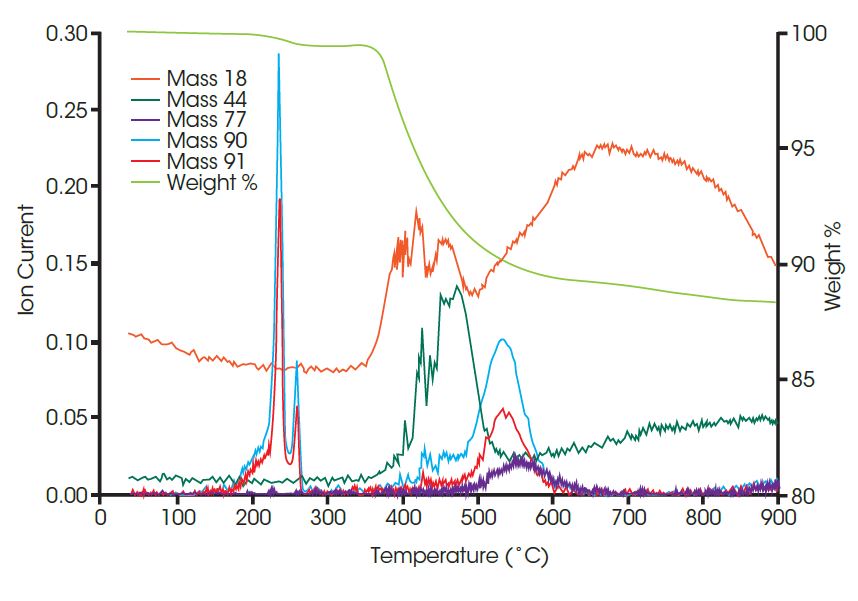

The Pfeiffer ThermoStarMS® is a benchtop quadrupole mass spectrometer, designed and optimized for evolved gas analysis. It features industry-standard technology configured for the efficient transfer, and rapid detection of offgas from the TGA furnace. Parts per billion (ppb) sensitivity is ensured with a state-of-the-art quadrupole detection system, including a cross-beam ion source, a single mass filter and a dual (Faraday and Secondary Electron Multiplier) detector system. This analyzer configuration is selected to optimize sensitivity and long-term stability performance.

Control of the experimental parameters and analysis of the mass spectral data is achieved through a user-friendly, recipe-driven software interface. Data collection can be triggered directly from the TGA software, and the resulting MS data can be combined with the corresponding TGA results for direct overlaying and comparison.

| Parameter | Performance |

| Mass range | 1-300 amu |

| Mass Resolution | 0.5 amu |

| Sensitivity | < 100 ppb (gas-dependent) |

| Ionization Source | Electron Ionization |

| Detector System | Dual (Faraday and Second Electron Multiplier) |

| Sample Pressure | 1 atm (nominal) |

| Bar Graph and Multiple Ion Detection | Bar graph and Peak Jump |

| Scanning Speed | |

| Bar graph Mode | 500 amu/s |

| Multiple Ion Detection | 500 channels/s |

| Transfer Line Temperature | 200°C |

| Transfer line | 2.0 meters, flexible |

| Filaments | Dual, customer changeable |

| Capillary | Quartz, changeable |

| Capillary size | I.D. = 0.15 mm |

| Inputs | Data collection controlled by TGA Trigger |

Hi-Res™ TGA

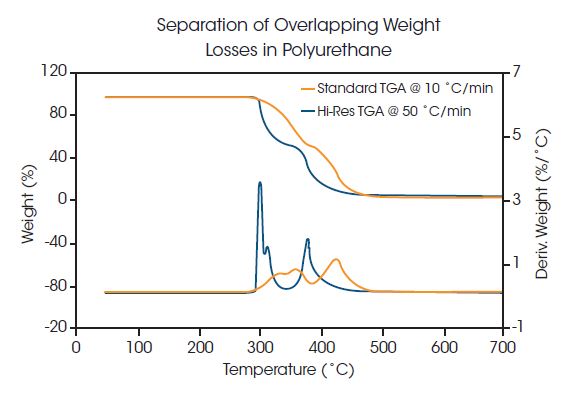

In Hi-Res TGA, the heating rate is controlled by the decomposition rate of the sample. The Discovery TGA 5500 and 550 designs are ideal for these measurements with rapid response furnaces for precise temperature control, and sensitive thermobalances designed to quickly detect small weight changes.

Benefits of Hi-Res TGA include:

- Separation of broad and overlapping weight losses

- Increased productivity with better resolution

- Rapid survey over wide temperature range with excellent resolution

- Simple method set up

The figure above shows the Hi-Res TGA results for a polyurethane material by standard and Hi-Res TGA. The superior resolution provided by the Hi-Res technique is clearly evident in both the TGA weight loss and the first derivative (DTG) signals. The latter signal is especially useful in defining the onset and the end-set of the individual weight loss segments, as well as indicating subtle events that provide a “fingerprint” of the sample.

Blending Gas Delivery Module (GDM)

Blending Gas Delivery Module (GDM) for the Discovery TGA 550 and TGA 5500

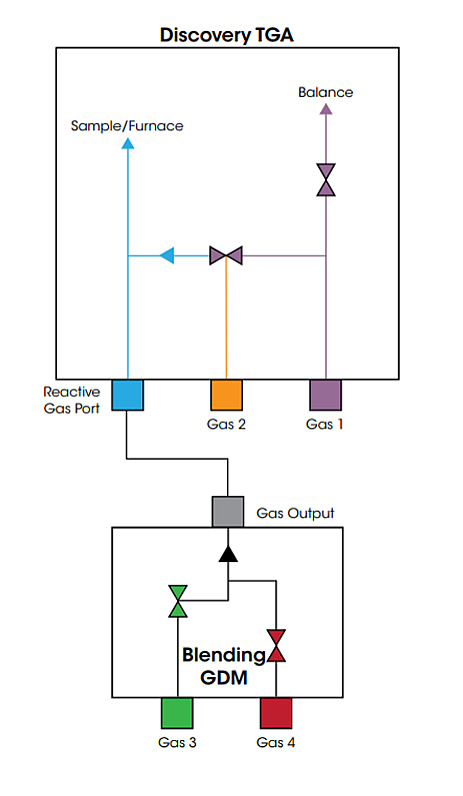

The Blending Gas Delivery Module (GDM) delivers flexibility in gas handling on the Discovery TGA 5500 and TGA 550. The GDM is an external accessory with two additional gas inlet ports that connect to the reactive gas port on the TGA. The GDM used in conjunction with the TGA allows for automated switching between the gas ports, as well as software-controlled blending of binary mixtures of gases. The added capability to perform controlled blending of binary gas mixtures allows for TGA experiments to be carried out in an atmosphere where the concentration of gases may be in a fixed ratio, stepped incrementally or ramped at a controlled rate. The GDM is compatible with Nitrogen, Argon, Helium, Air, Oxygen, Carbon Dioxide, Carbon Monoxide and Forming Gas (4%H2/96% N2). This accessory can be used to study sorption of gasses onto a material at atmospheric pressure, Redox reactions, and thermal stability of materials in a controlled atmosphere.

MTGA™

MTGA™

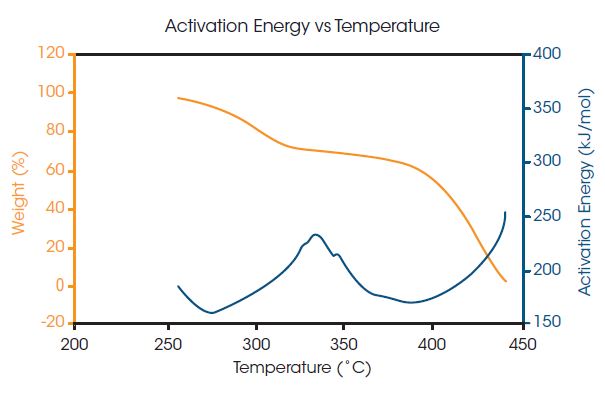

TA’s patented MTGA* is another TA Instruments innovation that offers advantages for material decomposition studies. Developed from the proprietary heater control technology utilized by Hi-Res TGA and MDSC, MTGA produces model-free kinetic data. Activation energy can be calculated real-time and studied as a function of time, temperature, and conversion.

Benefits of MTGA include:

- Increased productivity for studying kinetics

- Model-free kinetic data

- Can be combined with Hi-Res for better separation of overlapping weight losses

- Direct measurement of activation energy

EGA Furnace

EGA Furnace

Optional Evolved Gas Analysis (EGA) furnace for the TGA 55 and TGA 550.

Features & Benefits

- Ambient to 1000 °C

- Heating rates of 0.1 to 50 °C/min linear controlled

- Low volume, vacuum tight, and quartz lined for good evolved gas results

- Quartz liner makes furnace easy to clean

Autosampler

Autosampler

The NEW Discovery TGA features our new 25-position autosampler designed to be the most rugged and reliable system ever developed.

Autosampler Features and Benefits:

- Compatible with all pan types and sizes for ultimate flexibility.

- Sealed pan* and pan punch option for effective isolation of air-sensitive or volatile samples.

- Scheduled and unattended calibrations and verifications give scientists more time for research.

- Integrated electromagnet allows for unattended Curie point calibrations.[1]

- New TRIOS software makes it easier than ever to manage and run a large and diverse sample queue.

- The Design view and Running queue allow for quick and efficient autosampler programming.

[1] TGA 5500 only * U.S. Patent no. 6,840,668

IR Furnace

IR Furnace

The TGA 5500 is the only system offering patented infrared heating technology.

- Ambient to 1200 °C

- Linear controlled heating rates of 0.1 to 500 °C/min

- Ballistic heating rates >1500 °C/min for the highest efficiency available

- Fastest cooling for improved sample throughput

- Low volume, vacuum tight, and quartz lined with heated outlet option for best evolved gas results

- Quartz liner makes furnace easy to clean

- Integrated electromagnet for automated verification and calibration using Curie point standards

Sample Press

Sample Press

Proper sample preparation is of critical importance to the quality of data generated on a DSC. The Tzero sample encapsulation press and pans take into consideration every detail necessary by design to ensure simple and proper preparation for the highest data quality.

Tzero® Pans

Tzero high-performance pans and lids are designed to maximize pan flatness and sample contact. Coupled with the unparalleled flatness and uniformity of the Fusion cell sensor, the Tzero pans and lids provide the most direct, uniform heat flow path from the sample to the sensor. These pans are tolerant of many sample forms and are designed with lids that conform to the top of irregular specimens, efficiently transferring heat to and from the entire sample. Competitive pan designs that have non-flat bases are unable to achieve appropriate thermal contact with solid specimens. Fabricated using advanced technology and to extremely tight tooling specifications, the Tzero pans offer significant improvements in resolution and repeatability over any other pan design.

Tzero® DSC Sample Encapsulation Press

The Tzero press takes sample encapsulation to a higher level of performance and convenience in conventional and hermetic sealing of a wide variety of materials. The press kit includes four die sets for Tzero aluminum and hermetic pans & lids. Optional die sets are available for high-volume DSC pans and Discovery TGA sealed pans. The die sets are magnetically attached with no tools or adjustments required. In addition, each die set is color-coded to the box containing the compatible Tzero or standard aluminum hermetic pans and lids.

TGA Sealed Pans – Discovery TGA – Q5000

TGA Pans

TGA Pans

Pan Specifications

| Material | Size | Temperature Range |

Notes |

| Platinum | 50µL100µL | Ambient to 1000°C | Robust, high performance, reusable pans |

| Ceramic | 100µL 250µL | Ambient to 1200°C | Reusable pans for higher temperatures |

| Aluminum | 80µL | Ambient to 600°C | One time use, can be sealed to prevent volatilization before experiment |

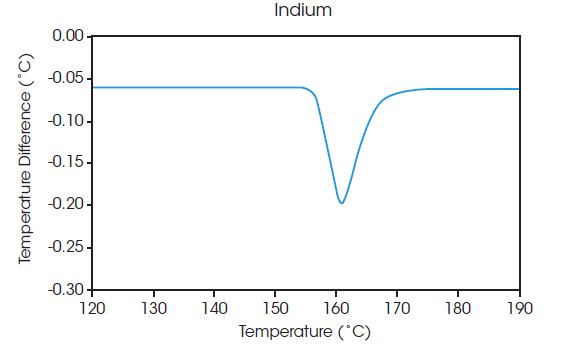

DTA signal

DTA signal

The DTA signal is a qualitative measurement of endothermic and exothermic reactions occurring in the TGA. This signal can also be used for temperature calibration by using melting point standards.

Glovebox Installation

Glovebox Installation

Adapter kit for seamless glovebox installation of Discovery TGA

Often high-performance materials react instantaneously with oxygen or humidity in ambient air, altering their properties and/or leading to safety risks due to uncontrolled exothermal reactions. Some examples for materials requiring inert protective atmosphere handling are Li-ion battery components, pharmaceuticals, chemicals used in semiconductor production and catalysts. An adapter kit enables seamless installation of Discovery TGA series instruments in the inert environment of a glovebox.

It has never been so simple to perform thermogravimetric analysis of atmosphere-sensitive materials in inert protective environments. Robust design and state-of-the-art technology ensure the TGA performance is not impacted, delivering the same accuracy and precision as when operated outside a glovebox.

Discovery TGA instruments can be operated in N2 or Ar purged gloveboxes covering all industries’ needs.

Features and Benefits:

- Glovebox operation of TA Instruments Discovery TGA provides reliable material data of atmosphere sensitive samples.

- No instrument modifications required to install Discovery TGA in a glovebox maintains accuracy of analysis data.

- N2-sensitive battery materials can be analyzed without contamination in argon (Ar) purged gloveboxes.

- Plug-and-play installation compatible with most glovebox brands and types through effectively designed installation kits employing standardized ISO-KF40 connections.