Keywords: Differential scanning calorimetry, DSC, polymers, epoxy

TA476

Introduction

Differential scanning calorimetry (DSC) measures the temperatures and heat flows associated with transitions in materials as a function of temperature or time in a controlled atmosphere. This technique provides quantitative and qualitative information about physical and chemical changes that involve endothermic or exothermic processes, or changes in heat capacity.

Experimental

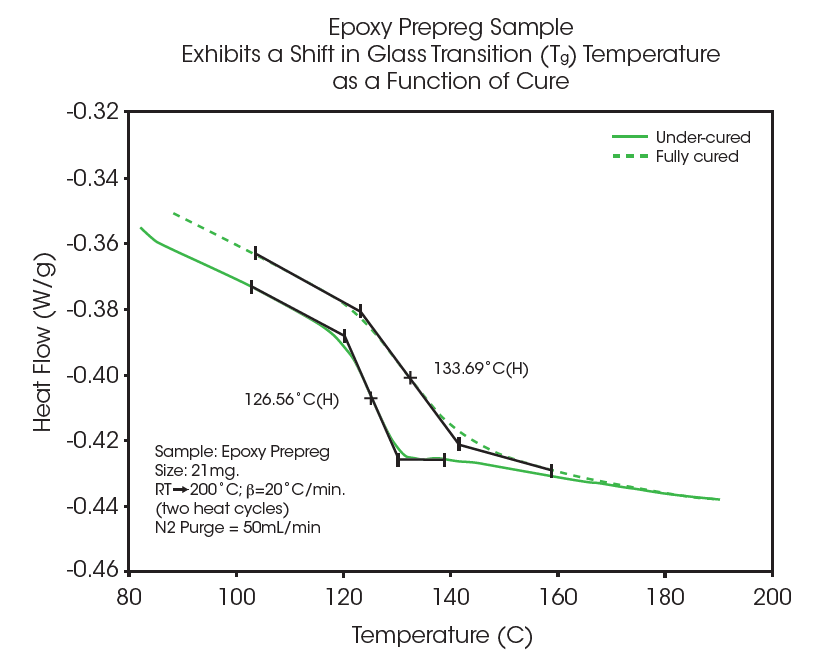

A TA InstrumentsTM differential scanning calorimeter was used to analyze an epoxy prepreg sample. A 21 mg sample was heated from room temperature to 200 °C at a rate of 20 °C/min. Two heat cycles were used under a nitrogen purge.

Results and Discussion

The thermal curve in Figure 1 shows two heat cycles on an epoxy prepreg used to manufacture printed circuit boards. DSC easily detects a shift in the glass transition (Tg) temperature indicating the sample, as received, was not fully cured. The undercured sample could affect assembly operations (i.e. hole drilling). This example clearly shows how the TA Instruments differential scanning calorimeters can be used to characterize materials in both a research and quality control setting.

Acknowledgement

Click here to download the printable version of this application note.