Analysis (DMA)

Dynamic Mechanical Analysis (DMA)

Backed by over four decades of TA Instruments’ expertise in rotational rheology and linear DMA measurements, the Discovery Hybrid Rheometer’s DMA Mode adds a new dimension for testing solid and soft-solid materials. Now in addition to the most sensitive and accurate rotational shear measurements, the DHR can deliver accurate linear Dynamic Mechanical Analysis (DMA) data. Axial DMA complements solid torsion testing by providing a direct measure of the modulus of elasticity, or Young’s Modulus (E). The new DMA mode is ideal for identifying a material’s transition temperatures and provides reliable measurements over the instrument’s full range of temperatures.

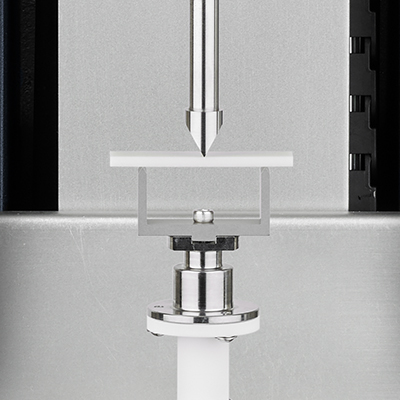

The axial DMA capability is enabled by the DHR’s active Force Rebalance Transducer (FRT) and patented magnetic bearing technologies that permit amplitude-controlled oscillatory deformation in the axial direction. During DMA measurements, the position of the active bearing is directly controlled to impose oscillatory linear deformation on the sample. Competitive instruments employing air bearings and passive normal force measurements are inherently incapable of such measurements due to design limitations.

Switching between rotational and linear testing is effortless since the geometries employ Smart SwapTM for installation in seconds. Compatible with the ETC oven and Relative Humidity accessory, the DMA capability is available in film tension, three-point bend, single and dual cantilever, and compression. Powered by the FRT technology available on all DHR models, the DMA mode does not require the installation of external components, so it is always quick and easy to get great data!

Specifications |

|

| Minimum Force in Oscillation | 0.003N |

| Maximum Axial Force | 50N |

| Displacement Resolution | 20nm |

| Axial Frequency Range | 6×10-5 rad/s to 100 rad/s (10-5 Hz to 16 Hz) |

Features and Benefits

- Force Rebalance Transducer Motor Control

- Smart SwapTM technology for quick installation

- Available on all DHR models

- Complete array of geometries for axial testing:

– 3-Point Bending

– Film/Fiber Tension

– Single and Dual Cantilever (Clamped Bending)

– Parallel Plate Compression

- Axial Force Control tracks material stiffness and automatically adjusts static load

- Superior temperature control with the Environmental Test Chamber (ETC) up to 600 °C

- Liquid Nitrogen cooling to −160 °C

- Air Chiller Systems provide liquid nitrogen-free cooling to −85 °C

- Optional sample visualization with ETC camera

DMA Applications

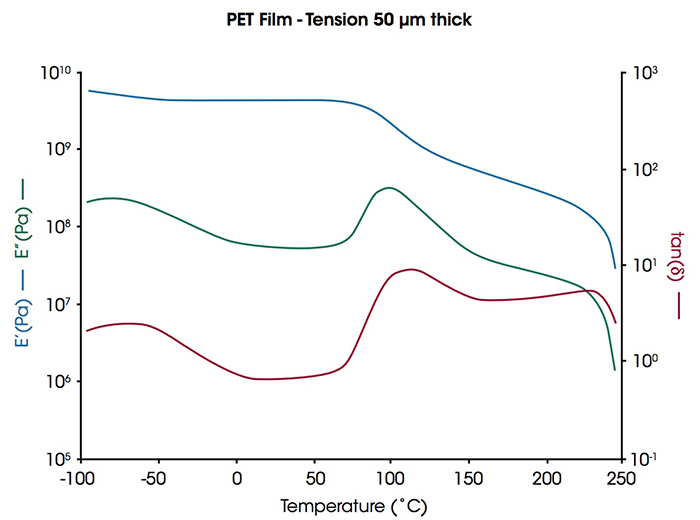

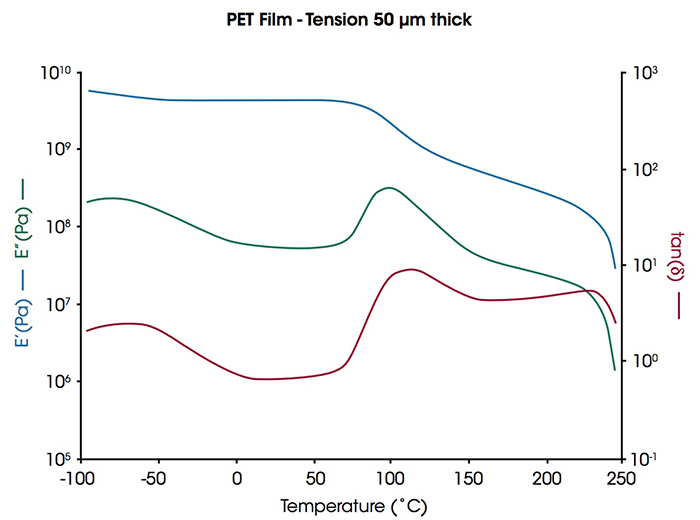

PET Film - Tension

Axial DMA tests on thin films requires maintaining the axial force above the oscillation force to hold the sample in tension throughout the test. This capability is highlighted in the plot showing a temperature ramp on 50μm thick PET film tested using tension geometry over a temperature range of -100 °C to 250 °C. Three major transitions are observed: a beta glass transition at -80°C, an alpha glass transition at about 111 °C, and melting at 236 °C. The data reveal a semi-crystalline structure with two amorphous relaxations and the DHR’s force-tracking capabilities in such tests

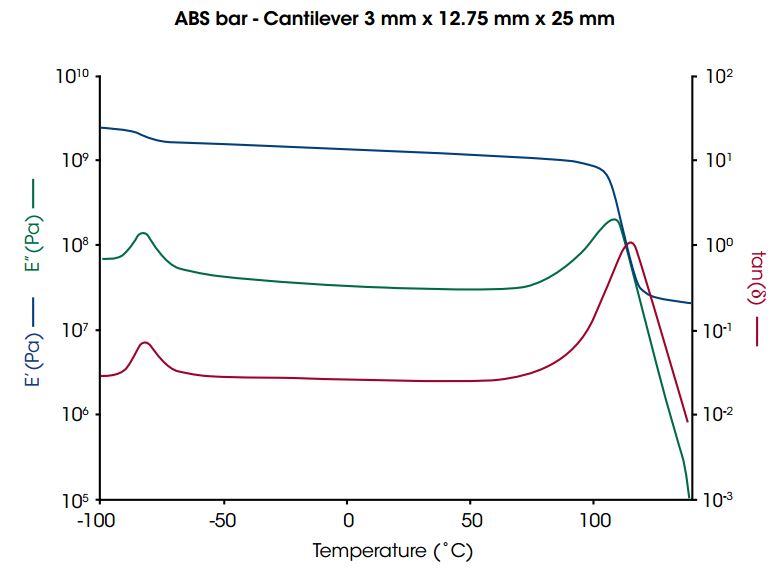

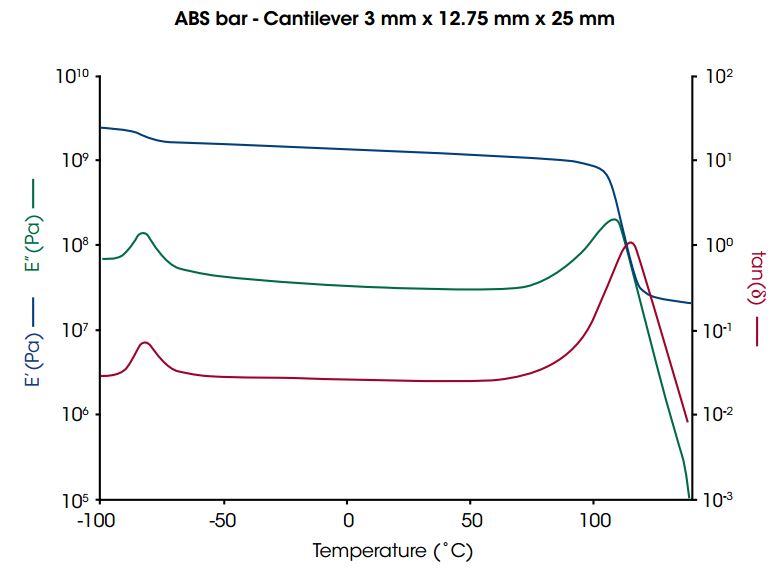

ABS bar - Cantilever

The figure above demonstrates the performance on the DMA mode during a temperature ramp run on an acrylonitrile butadiene styrene (ABS) sample in single cantilever over a temperature range of -100 °C to 140 °C. Two major transitions corresponding to the individual glass transitions of the styrene (-82 °C) and butadiene (115 °C) components are evident, indicating the incompatibility of the two monomers.

- Description

-

Dynamic Mechanical Analysis (DMA)

Backed by over four decades of TA Instruments’ expertise in rotational rheology and linear DMA measurements, the Discovery Hybrid Rheometer’s DMA Mode adds a new dimension for testing solid and soft-solid materials. Now in addition to the most sensitive and accurate rotational shear measurements, the DHR can deliver accurate linear Dynamic Mechanical Analysis (DMA) data. Axial DMA complements solid torsion testing by providing a direct measure of the modulus of elasticity, or Young’s Modulus (E). The new DMA mode is ideal for identifying a material’s transition temperatures and provides reliable measurements over the instrument’s full range of temperatures.

- Technology

-

The axial DMA capability is enabled by the DHR’s active Force Rebalance Transducer (FRT) and patented magnetic bearing technologies that permit amplitude-controlled oscillatory deformation in the axial direction. During DMA measurements, the position of the active bearing is directly controlled to impose oscillatory linear deformation on the sample. Competitive instruments employing air bearings and passive normal force measurements are inherently incapable of such measurements due to design limitations.

Switching between rotational and linear testing is effortless since the geometries employ Smart SwapTM for installation in seconds. Compatible with the ETC oven and Relative Humidity accessory, the DMA capability is available in film tension, three-point bend, single and dual cantilever, and compression. Powered by the FRT technology available on all DHR models, the DMA mode does not require the installation of external components, so it is always quick and easy to get great data!

- Specifications & Features

-

Specifications

Minimum Force in Oscillation 0.003N Maximum Axial Force 50N Displacement Resolution 20nm Axial Frequency Range 6×10-5 rad/s to 100 rad/s

(10-5 Hz to 16 Hz)Features and Benefits

- Force Rebalance Transducer Motor Control

- Smart SwapTM technology for quick installation

- Available on all DHR models

- Complete array of geometries for axial testing:

– 3-Point Bending

– Film/Fiber Tension

– Single and Dual Cantilever (Clamped Bending)

– Parallel Plate Compression

- Axial Force Control tracks material stiffness and automatically adjusts static load

- Superior temperature control with the Environmental Test Chamber (ETC) up to 600 °C

- Liquid Nitrogen cooling to −160 °C

- Air Chiller Systems provide liquid nitrogen-free cooling to −85 °C

- Optional sample visualization with ETC camera

- Applications

-

DMA Applications

PET Film - Tension

Axial DMA tests on thin films requires maintaining the axial force above the oscillation force to hold the sample in tension throughout the test. This capability is highlighted in the plot showing a temperature ramp on 50μm thick PET film tested using tension geometry over a temperature range of -100 °C to 250 °C. Three major transitions are observed: a beta glass transition at -80°C, an alpha glass transition at about 111 °C, and melting at 236 °C. The data reveal a semi-crystalline structure with two amorphous relaxations and the DHR’s force-tracking capabilities in such tests

ABS bar - Cantilever

The figure above demonstrates the performance on the DMA mode during a temperature ramp run on an acrylonitrile butadiene styrene (ABS) sample in single cantilever over a temperature range of -100 °C to 140 °C. Two major transitions corresponding to the individual glass transitions of the styrene (-82 °C) and butadiene (115 °C) components are evident, indicating the incompatibility of the two monomers.