Characterize and Improve Your Polymer Materials at Every Stage of Manufacture

TA Instruments | Waters have put together four lab packages designed specifically for your polymer lab. Accelerate product innovation, implement process improvements, and position your lab for success in meeting your organization’s sustainability goals with an in-depth understanding of polymer processing and functional properties.

RESIN CHARACTERIZATION PACKAGE

Accurately Characterize Resins and Optimize Processing

The superior measurement sensitivity of the HR 30 and flat baseline of the Discovery DSC deliver measurement quality you can depend on. Viscoelastic measurements can be used to gain insight into the molecular weight and molecular weight distribution, while DSC can be used to examine the impact of thermal history and formulation changes on the polymer properties and crystallization behavior. Whether you are gaining insight for research and development or for quality control purposes, TA Instruments guarantee your confidence in your measurements.

Pairing the HR 30 and DSC 2500 helps polymer labs:

- Directly link molecular architecture with processing and product performance properties

- Use data to optimize formulations and conditions, saving time and money

- Test solid polymer samples in bending or torsion with the HR’s DMA capabilities

- Characterize final product performance properties including impact resistance, blending homogeneity, structural performance, and glass transition temperature

The HR 30 and DSC 2500 offer 3 instruments in 2 with the HR’s fully integrated DMA capabilities. You can go from monitoring the cure reaction to solids testing with a simple geometry swap and minimal training. Gain complete characterization of your polymers without sacrificing valuable bench space.

PHASE CHANGES AND PROCESSING PACKAGE

Quantify Phase Changes and Streamline Processing

Understanding the temperatures at which polymers soften and melt is fundamental to polymer processing. As one of the first steps in extrusion, injection molding, and film blow molding processes, resin pellets are routinely heated past the melting point; in processes like thermoforming and blow molding, the resin is heated above its glass transition temperature to soften it, but without completely melting it.

These transitions can be measured using Differential Scanning Calorimetry (DSC) while Thermogravimetric Analysis (TGA) measures the temperature at which significant weight loss starts to take place, known as the onset of degradation. TGA results help establish the upper-temperature limits for subsequent testing.

Optimize processing and prevent failure

Combining DSC and TGA helps you design every step of formulation and processing for success. Phase transition measurements from DSC enables you to design processing conditions around polymers’ limits, creating the most efficient method for desirable results. Then, TGA measurements offer degradation limits so users know how far they can push their polymer in processing and performance.

DURABILITY AND PERFORMANCE PACKAGE

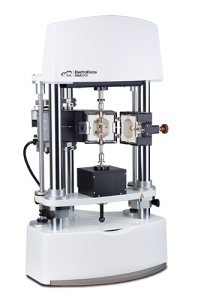

Complete Mechanical Characterization from Conventional and High Force DMA

Conventional DMA testing with the DMA 850 provides unparalleled precision and sensitivity to detect subtle changes in modulus from formulation, crosslinking, and crystallization. High Force DMA testing with the DMA 3200 allows application-relevant forces and strains on larger samples to understand the influence of geometry, processing, and strains beyond the Linear Viscoelastic Region (LVR). Combining these attributes provides a more complete insight into your polymer’s structure and properties.

Combining Conventional DMA and High Force DMA helps polymer labs measure:

- Strength and durability

- Young’s modulus

- Yield Strength

- Ultimate strength

- Fatigue life

All under numerous environmental and deformation conditions. Plus, a variety of ovens and fixtures enable measurements across a wide range of sample sizes including components. These measurements ensure your material will survive the demanding conditions expected by your customers.

POLYMER SYNTHESIS AND PERFORMANCE PACKAGE

Directly link molecular architecture with processing and product performance properties

Polymer architecture, molecular weight, and molecular weight distribution drive processing behavior and product performance. Rheology data acts as a fingerprint of polymer systems through viscoelastic characterization and melt viscosity measurements. Gain clarity on architecture to confirm polymer synthesis and predict polymer processing and product performance with the ARES-G2 rheometer for research and development or quality control purposes.

The ARES-G2 offers polymer labs:

- Temperature uniformity and absence of sample degradation for accurate measurements

- Forced convection oven (FCO) for the most uniform, responsive, and oxygen exclusive sample testing environment on the market

- Fully integrated DMA capabilities to test solid polymer samples in bending or torsion

- Measurements of key product performance properties including impact resistance, blending homogeneity, structural performance, and glass transition temperature

Insights into polymer characteristics and processing conditions are only as accurate as the measurements themselves. The ARES-G2 provides industry-leading accuracy, ease-of-use, and versatility. Confidently characterize polymer behavior across all stages of processing, from melts to solids and more, with minimal training and simple geometry swaps.