Rheo-Impedance offers unmatched data quality in simultaneous electrical impedance and rheological measurements to assess electrode slurries under process-relevant conditions, helping ensure successful battery performance.

Rheo-Impedance Spectroscopy offers powerful insights into microstructure of complex fluids such as battery electrode slurries, emulsions, paints, coatings, and more. Coupling dielectric impedance spectroscopy with the DHR’s rheology measurements empowers users to characterize shear-induced changes in sample microstructures under process-relevant conditions such as mixing, storage, and coating. Simultaneous precise measurements of viscosity, yield stress, viscoelasticity, and recovery deliver new insights connect flow properties to underlying changes in microstructure.

Battery electrode slurry formulation and process development is guided by impedance spectroscopy. Initial impedance measurements performed without applied shear indicate the dispersion of conductive material in the slurry after mixing. Simultaneous impedance and rotational deformation directly measures shear-induced changes in the microstructure, replicating slurry coating conditions and enabling measurements of time-dependent recovery after shear. These new insights verify the electrically conductive network is maintained in the finished electrode and ensure successful battery performance.

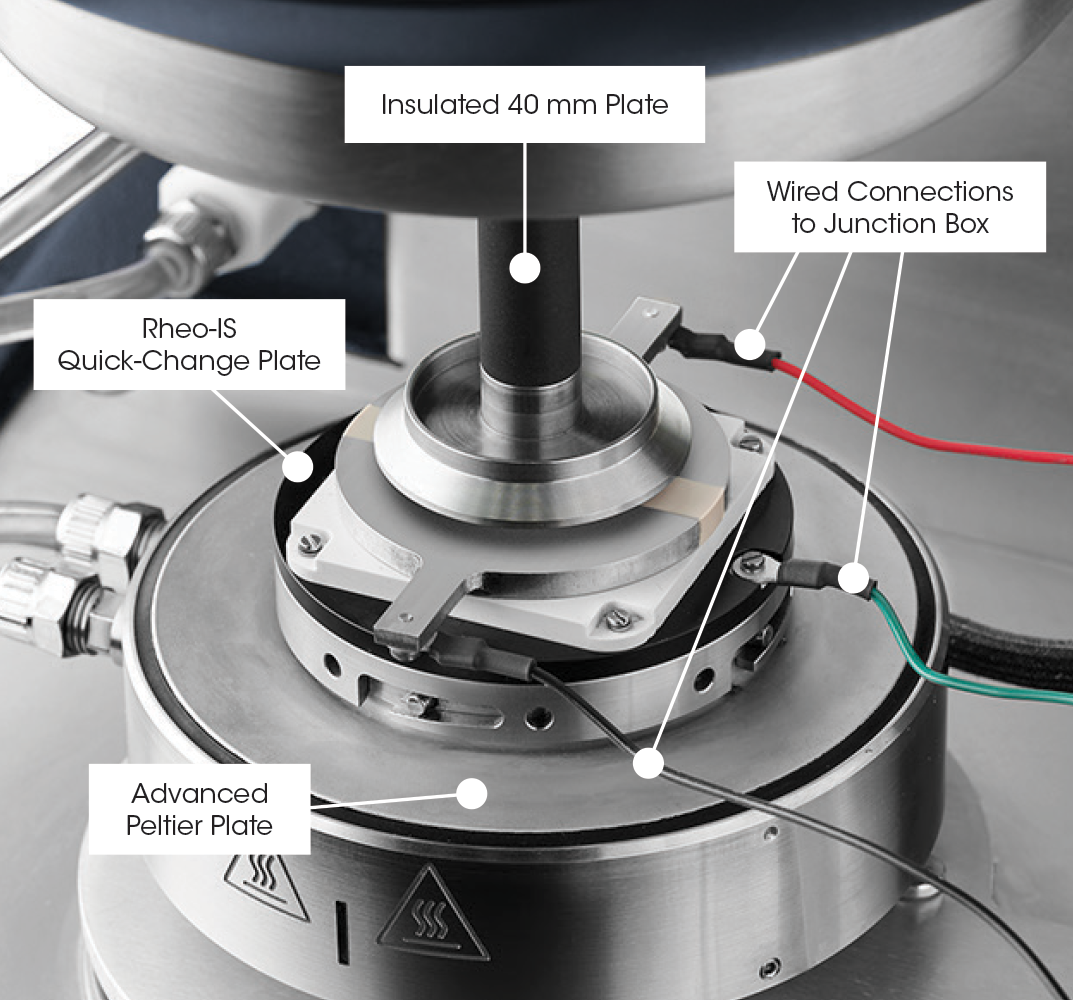

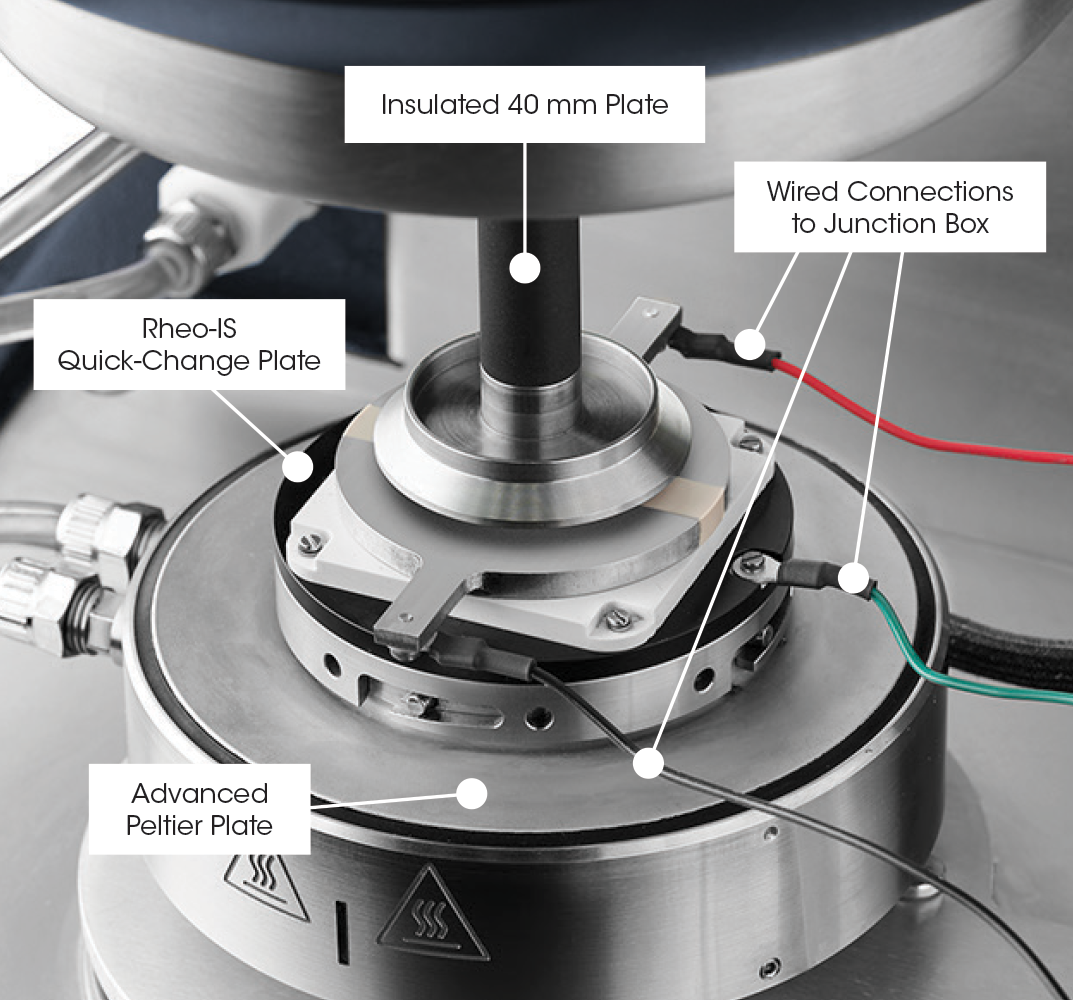

The DHR’s Rheo-Impedance Spectroscopy accessory achieves unmatched data quality in both dielectric impedance and rheology measurements.Traditional approaches to combined rheology-dielectric impedance require an electrical contact with the upper tool, either hard-wired, spring contact, or liquid electrolyte, limiting measurement range. The Rheo-Impedance accessory positions both electrodes on a lower plate, using an insulated upper parallel plate geometry as a conductor, eliminating any need for contact with the upper tool. This unique design enables unlimited Rheo-Impedance measurements:

- Simultaneous impedance and steady shear measurements under process-relevant conditions

- Friction-free: absence of wire or spring contacts allows for full range of the DHR’s torque sensitivity, enabling precise characterization of viscosity, yield stress, viscoelasticity and structure recovery

- Dielectric impedance measurements up to 8 MHz, without the limitations and experimental challenges of a liquid electrolyte contact

- Installation in under 5 minutes: Rheo-IS Quick Change plate mounts to Advanced Peltier Plate for controlled temperature

- LCR meter calibration, measurement, signals and data analysis integrated in TRIOS software

| Rheo-Impedance Spectroscopy Accessory | ||

|---|---|---|

| Unique Friction-Free technology | Minimum oscillation torque 0.3 nN.m * | |

| Peltier Temperature control | 15 °C to 100 °C | |

| 40 mm stainless steel plate (included) | Sample volume < 2 mL | |

| Customized solvent trap (included) | Prevent evaporation during measurement | |

| TRIOS software integration of LCR data | Reactance, resistance, loss tangent, impedance, admittance, capacitance, conductivity, permittivity, susceptance; Nyquist plot, Bode plot | |

| Compatible LCR Meters | Frequency | Voltage |

|---|---|---|

| HIOKI – IM3536 | 4 Hz to 8 MHz | 0.01 V to 5 V |

| Keysight – E4980AL | 20 Hz to 1MHz | 0.001 V to 2 V |

| Keysight – E4980A | 20 Hz to 2 MHz | 0.005 V to 20 V |

*minimum torque depends on instrument model

Cathode Slurry Formulation

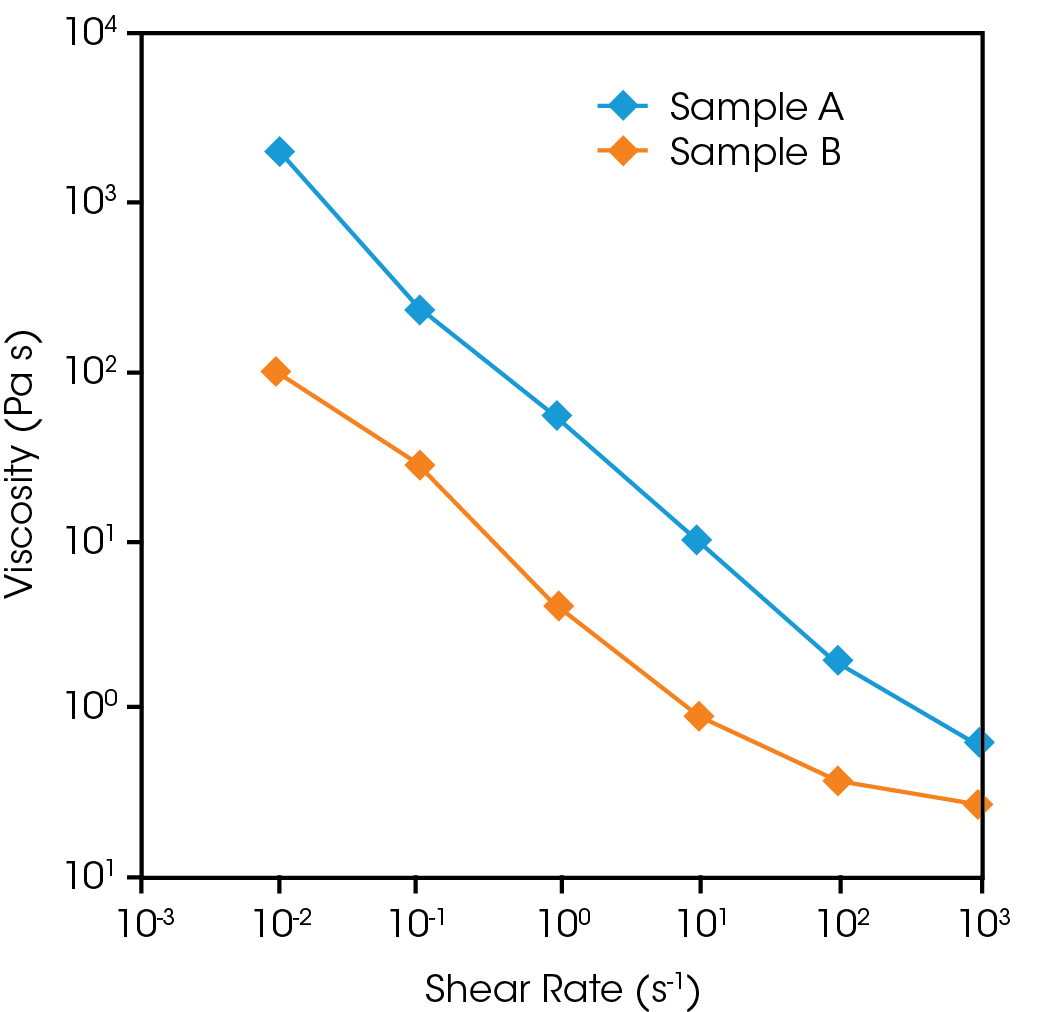

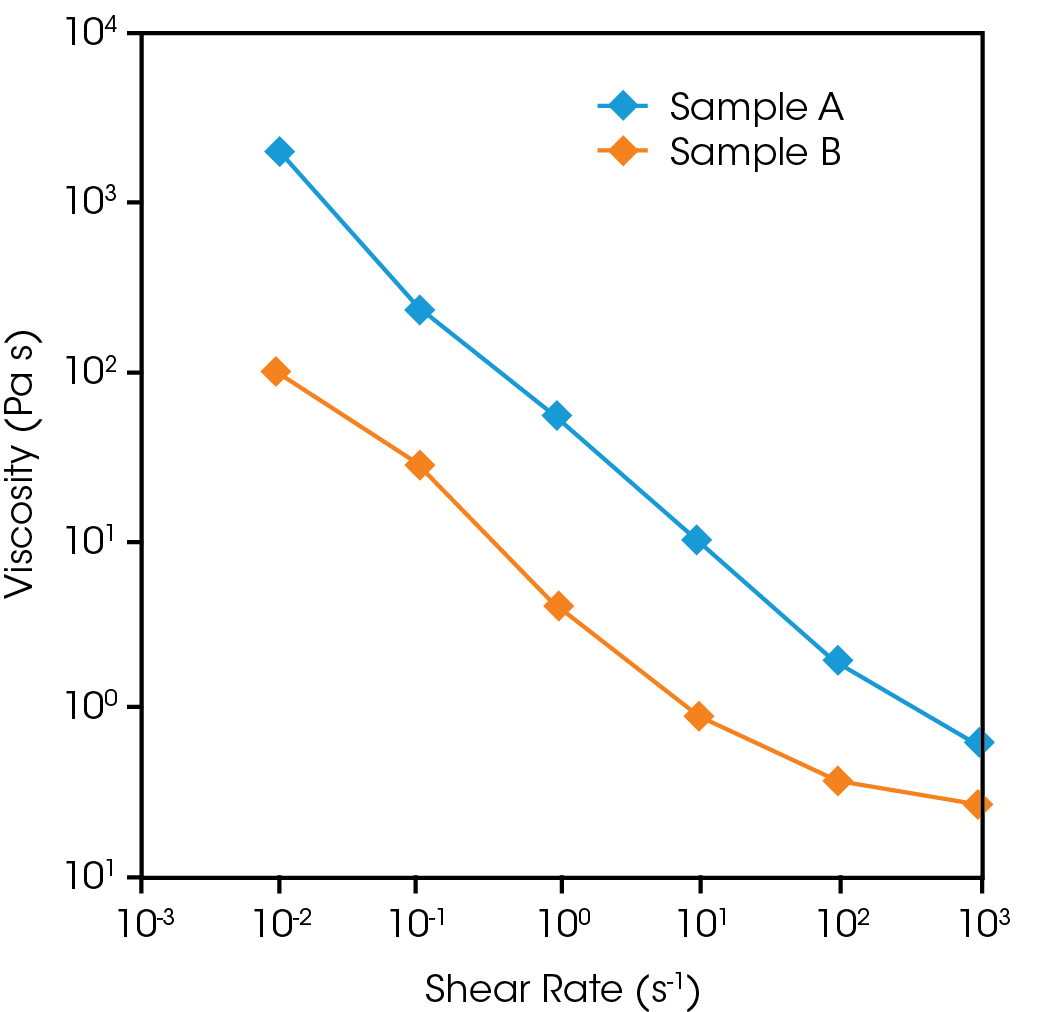

Rheo-Impedance Spectroscopy offers powerful insights into cathode slurry formulation, evaluating each ingredient’s impact on both rheology and conductive network distribution. A cathode slurry was prepared by first mixing carbon black and PVDF in NMP (Sample A), then adding NMC (Sample B). Impedance measurements were made on the material at both steps, over a range of increasing shear rates. Sample A’s viscosity is significantly higher, despite its low solids content (8%), compared to Sample B with added NMC (solid content: 72%). NMC particles aid in dispersing carbon black agglomerates into a more uniform network, resulting in a reduced viscosity preferable for coating.

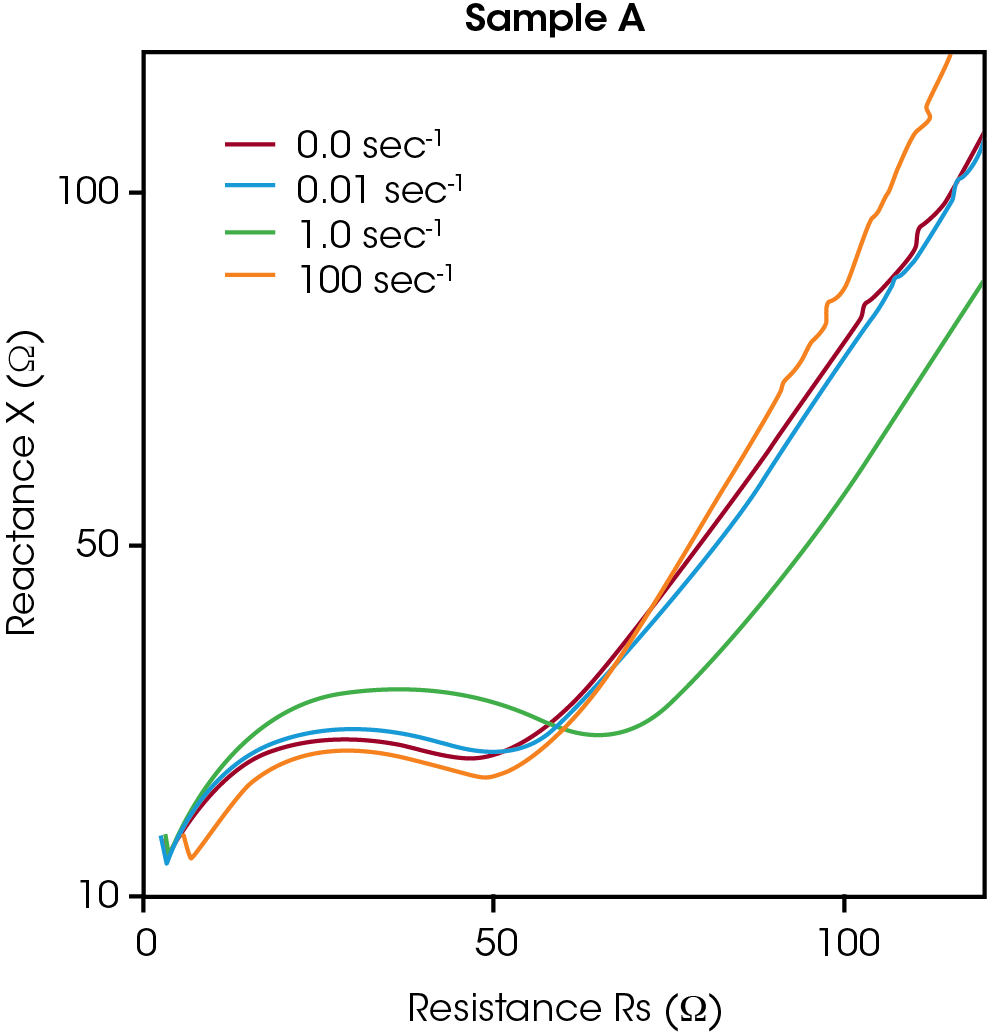

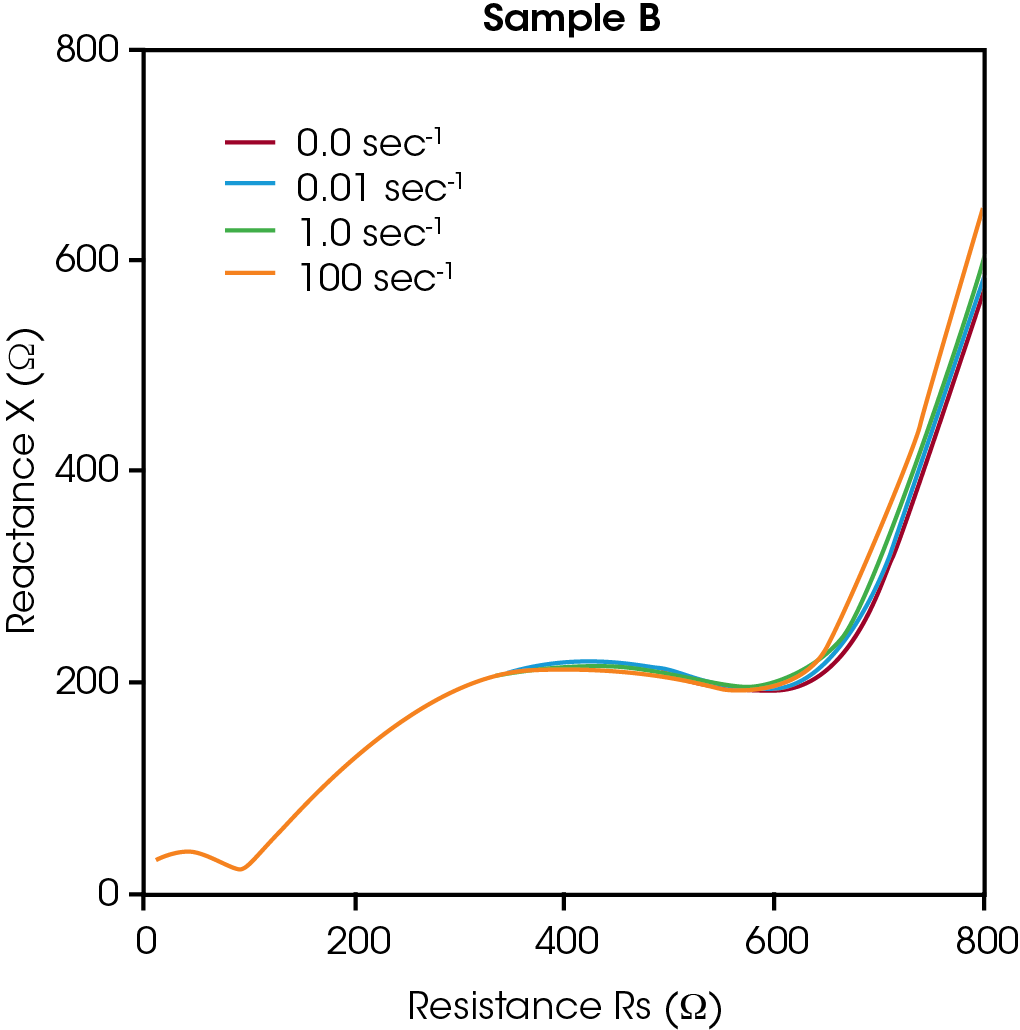

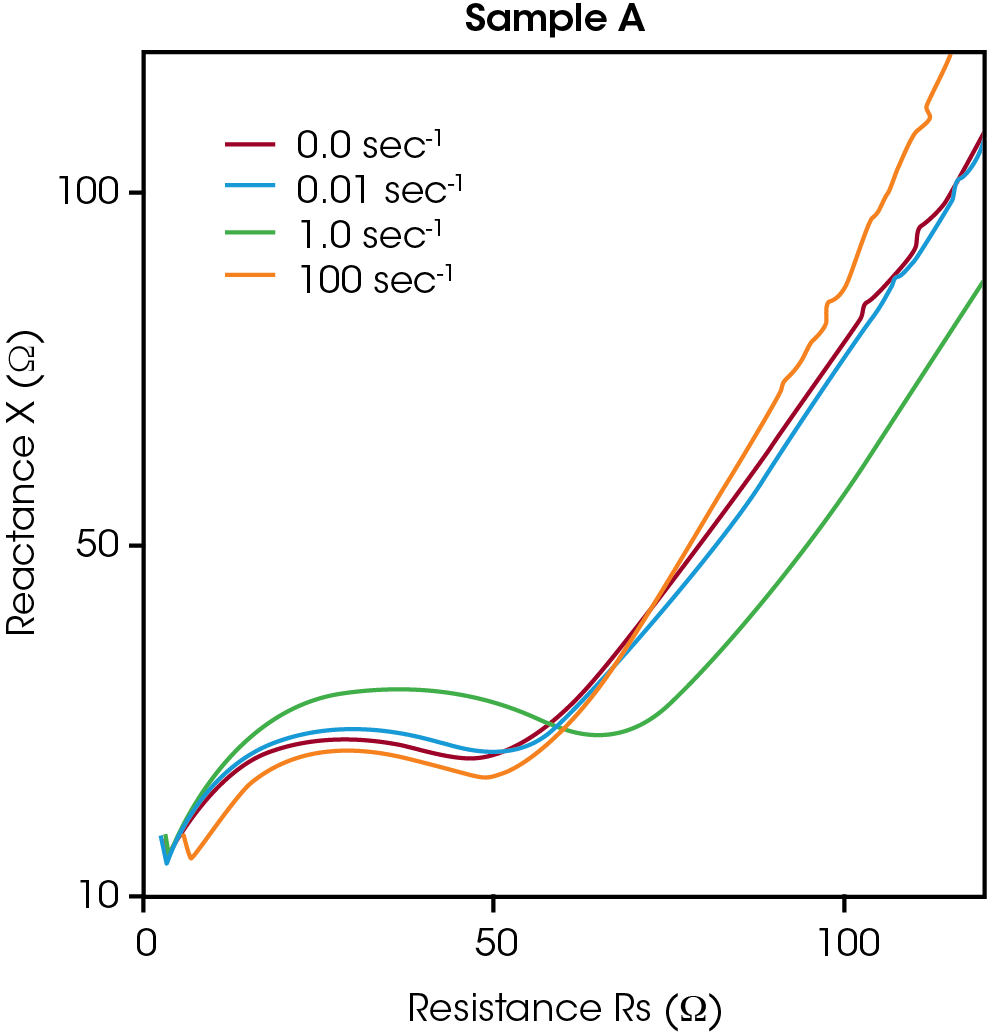

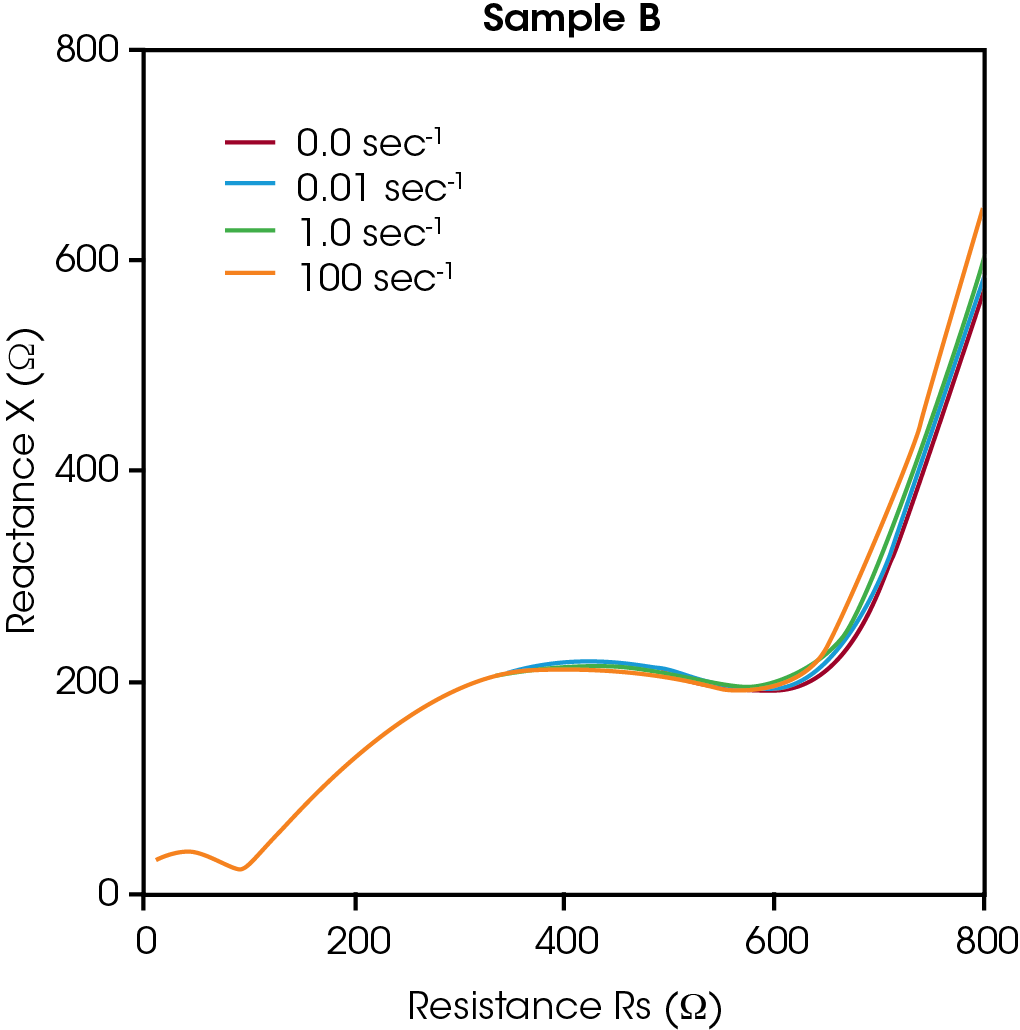

Simultaneous impedance measurements support this explanation. A Nyquist plot of Sample A show its impedance changes significantly under varying shear rates, indicative of a changing network of carbon black agglomerates. In contrast, Sample B shows consistent impedance across all shear rates. The incorporation of NMC aids in the distribution of carbon black, resulting in a more stable electrically conductive network. This shear-stable microstructure is favorable for production, ensuring the conductive network is maintained in the finished cathode.

- Description

-

Rheo-Impedance Spectroscopy offers powerful insights into microstructure of complex fluids such as battery electrode slurries, emulsions, paints, coatings, and more. Coupling dielectric impedance spectroscopy with the DHR’s rheology measurements empowers users to characterize shear-induced changes in sample microstructures under process-relevant conditions such as mixing, storage, and coating. Simultaneous precise measurements of viscosity, yield stress, viscoelasticity, and recovery deliver new insights connect flow properties to underlying changes in microstructure.

Battery electrode slurry formulation and process development is guided by impedance spectroscopy. Initial impedance measurements performed without applied shear indicate the dispersion of conductive material in the slurry after mixing. Simultaneous impedance and rotational deformation directly measures shear-induced changes in the microstructure, replicating slurry coating conditions and enabling measurements of time-dependent recovery after shear. These new insights verify the electrically conductive network is maintained in the finished electrode and ensure successful battery performance.

- Technology

-

The DHR’s Rheo-Impedance Spectroscopy accessory achieves unmatched data quality in both dielectric impedance and rheology measurements.Traditional approaches to combined rheology-dielectric impedance require an electrical contact with the upper tool, either hard-wired, spring contact, or liquid electrolyte, limiting measurement range. The Rheo-Impedance accessory positions both electrodes on a lower plate, using an insulated upper parallel plate geometry as a conductor, eliminating any need for contact with the upper tool. This unique design enables unlimited Rheo-Impedance measurements:

- Simultaneous impedance and steady shear measurements under process-relevant conditions

- Friction-free: absence of wire or spring contacts allows for full range of the DHR’s torque sensitivity, enabling precise characterization of viscosity, yield stress, viscoelasticity and structure recovery

- Dielectric impedance measurements up to 8 MHz, without the limitations and experimental challenges of a liquid electrolyte contact

- Installation in under 5 minutes: Rheo-IS Quick Change plate mounts to Advanced Peltier Plate for controlled temperature

- LCR meter calibration, measurement, signals and data analysis integrated in TRIOS software

- Specifications

-

Rheo-Impedance Spectroscopy Accessory Unique Friction-Free technology Minimum oscillation torque 0.3 nN.m * Peltier Temperature control 15 °C to 100 °C 40 mm stainless steel plate (included) Sample volume < 2 mL Customized solvent trap (included) Prevent evaporation during measurement TRIOS software integration of LCR data Reactance, resistance, loss tangent, impedance, admittance, capacitance, conductivity, permittivity, susceptance; Nyquist plot, Bode plot Compatible LCR Meters Frequency Voltage HIOKI – IM3536 4 Hz to 8 MHz 0.01 V to 5 V Keysight – E4980AL 20 Hz to 1MHz 0.001 V to 2 V Keysight – E4980A 20 Hz to 2 MHz 0.005 V to 20 V *minimum torque depends on instrument model

- Applications

-

Cathode Slurry Formulation

Rheo-Impedance Spectroscopy offers powerful insights into cathode slurry formulation, evaluating each ingredient’s impact on both rheology and conductive network distribution. A cathode slurry was prepared by first mixing carbon black and PVDF in NMP (Sample A), then adding NMC (Sample B). Impedance measurements were made on the material at both steps, over a range of increasing shear rates. Sample A’s viscosity is significantly higher, despite its low solids content (8%), compared to Sample B with added NMC (solid content: 72%). NMC particles aid in dispersing carbon black agglomerates into a more uniform network, resulting in a reduced viscosity preferable for coating.

Simultaneous impedance measurements support this explanation. A Nyquist plot of Sample A show its impedance changes significantly under varying shear rates, indicative of a changing network of carbon black agglomerates. In contrast, Sample B shows consistent impedance across all shear rates. The incorporation of NMC aids in the distribution of carbon black, resulting in a more stable electrically conductive network. This shear-stable microstructure is favorable for production, ensuring the conductive network is maintained in the finished cathode.

- Resources