Unlocking Battery Slurry Insights:

Why TA Instruments’ Discovery Core and Hybrid Rheometers Are Essential Tools for Battery Scientists

Sam Barnes | Hang Lau

June 25, 2025

Battery slurry formulation and testing is a complex challenge that sits at the heart of lithium-ion battery performance. From slurry mixing to electrode coating, understanding the flow and structural behavior of slurries is critical. For battery scientists seeking precise, reliable characterization tools, rheometers are indispensable. TA Instruments offers two powerful solutions tailored to battery slurry research: the Discovery Core Rheometer and the Discovery Hybrid Rheometer.

If you’re searching for a high-quality viscometer or entry-level rheometer to handle battery slurry viscosity and flow properties, the Discovery Core Rheometer is the ideal choice. For advanced users requiring comprehensive rheological insights coupled with cutting-edge electrical characterization, the Discovery Hybrid Rheometer expands capabilities to new dimensions.

In this blog, we’ll explore how these instruments support battery slurry development — from mixing and transport to coating optimization — helping scientists design better batteries through precise rheological and impedance measurements.

Why Rheometry Matters for Battery Slurry Development

Battery slurries are complex multiphase systems composed of active material particles, conductive additives (like carbon black), binders, and solvents. Achieving the right slurry rheology ensures:

- Uniform slurry mixing without particle aggregation

- Stable slurry storage minimizing sedimentation

- Optimal pumpability and transport during manufacturing

- Precise electrode coating with controlled thickness and uniformity

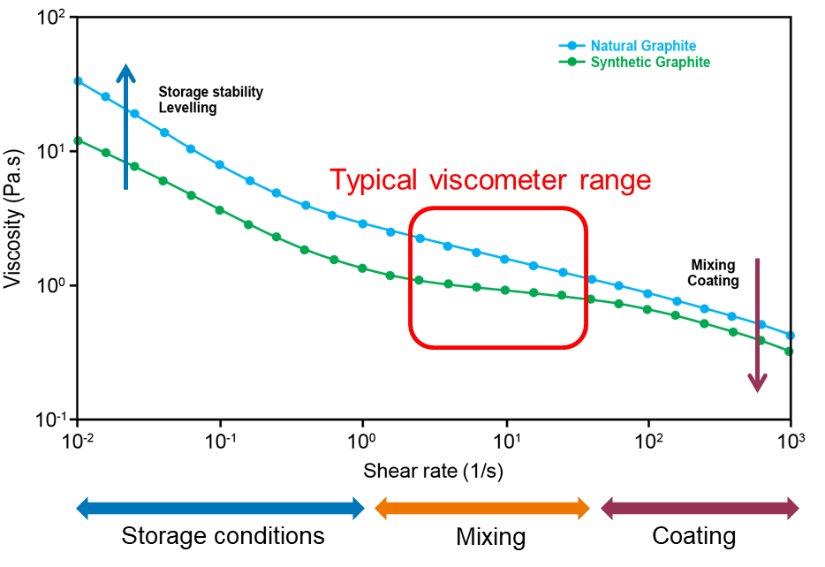

Characterizing the slurry’s flow behavior — including viscosity, yield stress, viscoelasticity, and thixotropy — is essential. These parameters dictate how the slurry will behave under shear forces encountered in mixing, pumping, and coating processes.

The Discovery Core Rheometer: The Essential Rheometry Solution for Battery Slurry Testing

For many battery scientists, precise viscosity and rheological measurements are critical but do not require the full range of advanced functionalities. The Discovery Core Rheometer provides a robust and versatile platform designed specifically for battery slurry formulation and testing needs:

Key Testing Capabilities

- Mixing for slurry formation: Accurately measure viscosity and shear thinning index to optimize particle dispersion.

- Slurry stability & storage: Assess zero shear viscosity and viscoelastic properties to predict and prevent settling or aggregation during storage.

- Pumpability & transport: Measure yield stress and viscoelasticity, critical for ensuring the slurry flows smoothly through pumps and pipes without clogging.

- Electrode coating: Evaluate viscosity (including thixotropy) and yield stress to optimize coating weight and thickness for uniform electrode layers.

This instrument delivers the comprehensive viscometry and rheometry measurements essential for battery slurry research — and is the recommended choice for scientists who may otherwise consider a basic viscometer for these tasks.

The Discovery Hybrid Rheometer: Advanced Rheological and Electrical Characterization for Cutting-Edge Battery Research

For battery scientists who require deeper insights into slurry microstructure, conductive networks, and environmental control, the Discovery Hybrid Rheometer offers all capabilities of the Core Rheometer plus powerful advanced features:

Enhanced Capabilities

- Friction-Free Rheo-Impedance Spectroscopy: Simultaneously measure rheology and electrical impedance to probe conductive networks under shear — critical for understanding carbon black dispersion and slurry conductivity.

- Powder Characterization: Study powder behavior during mixing and storage with the Powder Rheology Accessory.

- Inert Environment Operation: Compatible with glovebox and inert atmosphere (argon, nitrogen) environments, protecting sensitive materials from oxidation or reaction with moisture.

- Advanced Pumpability & Transport Analysis: Assess yield stress and complex viscosity profiles including Newtonian, shear thinning, shear thickening, and electro-rheological behaviors during processing condition.

The Hybrid Rheometer is purpose-built for advanced battery slurry research, delivering unparalleled insights into both rheological and electrochemical properties.

Why Choose a Discovery Core Rheometer Over a Viscometer?

While viscometers can measure basic viscosity, they lack the capability to capture the full rheological behavior necessary for battery slurry optimization. The Discovery Core Rheometer provides:

- Comprehensive Rheological Measurements: Beyond viscosity, measure viscoelasticity, yield stress, shear thinning, and thixotropy — properties crucial to slurry stability and processing.

- Wide Shear Rate Range: Accurately simulate real-world processing conditions from gentle storage to high-speed coating.

- Higher Sensitivity & Precision: Essential for detecting subtle changes in slurry behavior that impact battery performance.

- Versatility to Grow With Your Needs: Start with core measurements and upgrade to more advanced options if needed, protecting your investment.

For battery slurry formulation, the Discovery Core Rheometer is the superior choice, offering the accuracy and flexibility required to optimize formulations and processes.

Summary: Which TA Instruments Rheometer Should You Choose?

| Need / Application | Recommended Instrument |

|---|---|

| Basic viscosity & rheology testing | Discovery Core Rheometer |

| Full rheological characterization, including yield stress, viscoelasticity, thixotropy | Discovery Core Rheometer |

| Advanced research on slurry conductive networks, powder behavior, and inert environment operation | Discovery Core Rheometer |

| Simultaneous electrical & rheological measurement (Rheo-Impedance) | Discovery Core Rheometer |

Final Thoughts

Battery slurry development demands precision instruments capable of capturing complex flow and structural behaviors. TA Instruments’ Discovery Core and Hybrid Rheometers provide battery scientists with robust, adaptable platforms tailored to both fundamental and advanced slurry characterization needs.

If you’re considering a viscometer for slurry testing, the Discovery Core Rheometer offers significantly greater insight and flexibility — making it the preferred choice. For those who require integrated electrical characterization and powder analysis under inert conditions, the Discovery Hybrid Rheometer offers unmatched capabilities.

Ready to elevate your battery slurry research? Contact TA Instruments to explore how their rheometer solutions can empower your formulation and testing workflows.

Frequently Asked Questions (FAQs) — Rheometry & Viscometry for Battery Slurries

Q1: What is the difference between a rheometer and a viscometer for battery slurry testing?

A: A viscometer measures only viscosity, usually at a single or limited shear rates. A rheometer measures viscosity plus additional rheological properties like yield stress, viscoelasticity, shear thinning, and thixotropy, providing a comprehensive understanding of slurry behavior critical for battery manufacturing.

Q2: Why is measuring yield stress important for battery slurry formulations?

A: Yield stress indicates the stress required to initiate flow in a slurry. It affects pumpability, slurry transport, and coating uniformity. Knowing yield stress helps optimize slurry stability and ensures consistent electrode fabrication.

Q3: Can a viscometer simulate the shear conditions experienced during battery electrode coating?

A: Typically no. Viscometers have limited shear rate ranges and cannot capture complex shear-dependent behaviors. Rheometers provide wide shear rate capabilities to simulate processes from gentle storage conditions to high-shear coating environments.

Q4: What role does viscoelasticity play in battery slurry performance?

A: Viscoelasticity reflects the slurry’s combined viscous and elastic responses. It influences slurry stability, particle network formation, and resistance to sedimentation or aggregation, all critical for consistent electrode quality.

Q5: How does thixotropy affect slurry handling and coating?

A: Thixotropy is the time-dependent shear thinning behavior of slurries. It affects how slurry viscosity recovers after shear, impacting pumpability and coating uniformity.

Q6: Why would a battery scientist want simultaneous rheology and electrical impedance measurements?

A: Combining rheology and impedance (Rheo-Impedance Spectroscopy) reveals how mechanical deformation influences the conductive network within slurries, providing insights into electrode performance and manufacturing optimization.

Q7: Are rheometers compatible with sensitive battery materials?

A: Some rheometers, like the Discovery Hybrid Rheometer, can be operated in gloveboxes or inert atmospheres to protect sensitive materials (e.g., lithium or binders prone to oxidation).

Q8: Is investing in a rheometer worth it compared to a viscometer?

A: For battery slurry applications, rheometers offer much broader and deeper characterization capabilities essential to optimize slurry formulation, stability, and processability — making them the preferred tool over basic viscometers.

Other Resources

- Blog – Evaluating Battery Slurries with Simultaneous Rheological and Impedance Measurement

- eBook- Essential Battery Slurry Characterization Techniques

- eBook – Battery Testing Selection Guide

- White Paper – The Power of Powder Rheology for Lithium-Ion Battery Electrode Manufacturing

- Accessory – Rheo-Impedance Spectroscopy

- Contact – Contact TA Instruments Today