Precision Rheology for Drug Development: Why Pharmaceutical Scientists Trust the Discovery Core Rheometer

Calliste Scholl | Sarah Cotts

May 30, 2025

In the world of pharmaceutical formulation and development, the ability to precisely characterize the rheological behavior of drug delivery systems is critical to ensuring efficacy, stability, and processability. Whether developing a pediatric suspension, a topical corticosteroid, or an injectable biologic, pharmaceutical scientists need accurate, repeatable rheological data to drive successful outcomes across R&D, scale-up, and quality control.

Enter the TA Instruments Discovery Core Rheometer – the most intuitive, high-performance rheometer engineered specifically for fast-paced pharmaceutical environments. With built-in temperature control, automated geometry recognition, and the intuitive RheoGuide™ interface, the Discovery Core Rheometer delivers research-grade precision with the usability of a viscometer.

Why Rheology Matters in Pharmaceutical Formulation

Pharmaceutical fluids and semi-solids — oral suspensions, topical emulsions, injectables — often display non-Newtonian behavior. Their performance depends on properties like viscosity at different shear rates, yield stress, and viscoelastic modulus (G’, G”), all of which impact:

- Stability during storage

- Ease of dispensing

- Controlled application and bioavailability

- Batch-to-batch consistency

Viscometers cannot capture this complex behavior, making rheometers essential tools in pharmaceutical R&D and manufacturing.

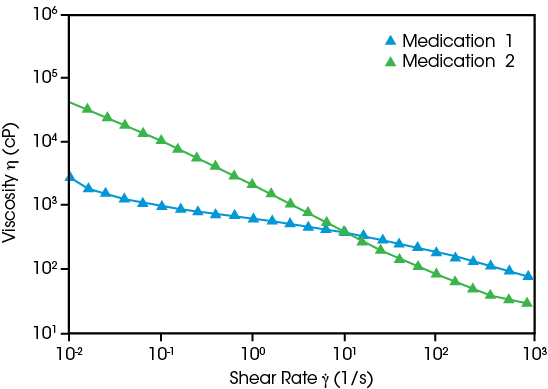

Application Example 1: Oral Suspensions – Consistent API Dosing

Oral suspensions such as infant ibuprofen rely on shear-thinning behavior to maintain homogeneous distribution of the active pharmaceutical ingredient (API) during storage while allowing easy flow during dispensing.

Rheological Insight:

- High viscosity at low shear rates maintains uniform API distribution.

- Shear thinning at higher rates prevents dripping and enables smooth oral administration.

Discovery Core Rheometer Advantages:

- Ultra-sensitive torque for low-viscosity detection

- Accurate viscosity flow curves across multiple shear rates

- Simple setup and temperature control via Core Temperature Technology

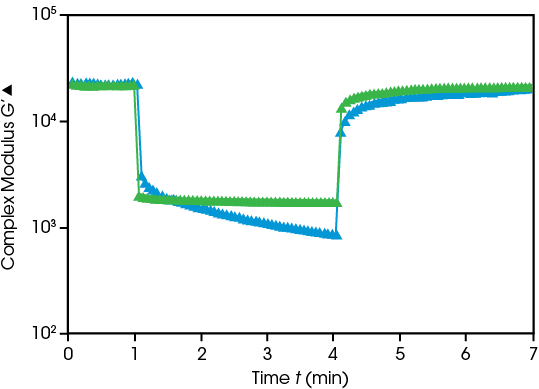

Application Example 2: Topical Emulsion Structure – Stability and Spreadability

Pharmaceutical creams and ointments must balance structural integrity with ease of application. Rheology reveals how emulsions like steroid creams or antibiotic ointments respond to stress and how quickly they recover post-application.

Rheological Insight:

- Storage modulus (G’) and loss modulus (G”) at rest indicate emulsion structure.

- Time-dependent structural recovery reveals formulation resilience.

Discovery Core Rheometer Benefits:

- Textured plates minimize slip in semi-solid testing

- Perform creep-recovery tests to measure structural rebuild

- Easy-to-follow methods with RheoGuide touchscreen software

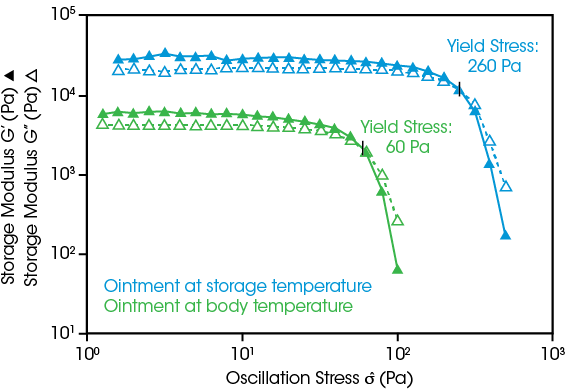

Application Example 3: Yield Stress vs. Temperature – Formulation and Use Conditions

Topical ointments must dispense easily at room temperature but remain stable at skin temperature (37°C). Measuring yield stress across temperatures helps formulators balance these competing demands.

Rheological Insight:

- Yield stress at 25°C ensures stable packaging

- Yield stress at 37°C ensures post-application adherence

Discovery Core Rheometer Capabilities:

- Accurate temperature control from -10°C to 200°C

- Quantify yield stress and flow behavior at relevant storage and application conditions

Discovery Core Rheometer in Drug Formulation and Development

Pharmaceutical scientists use the Discovery Core Rheometer to characterize a wide array of drug products:

| Drug Delivery System | Key Rheological Tests |

|---|---|

| Oral Formulations | Viscosity, Shear Thinning, Yield Stress |

| Topicals (creams, gels) | Viscosity Flow Curve, Creep-Recovery, Viscoelasticity |

| Injectables (biologics, solutions) | High Shear Rate Viscosity, Stability Testing |

With advanced capabilities to run temperature-controlled tests and automated analysis workflows, the Discovery Core Rheometer is optimized for both research labs and QA/QC environments.

The TA Instruments Discovery Core Rheometer – Features at a Glance

- Effortless Operation with RheoGuide™: Designed for maximum usability, RheoGuide™ simplifies every step of the testing process. From automatic geometry recognition and precision alignment to an intuitive touchscreen interface, users can run complex tests with minimal training. Built-in guidance and real-time results empower your lab to move beyond basic viscosity and unlock advanced rheological insights.

- Comprehensive Rheological Testing: Go beyond the limitations of traditional viscometers. The Discovery Core Rheometer accurately measures both viscosity and viscoelastic properties across a wide spectrum of materials. Its versatility supports everything from low-viscosity injectables to semi-solid topicals, delivering a deeper understanding of material performance for formulation, stability, and processing.

- Optimized for Quality Control and Manufacturing: Streamline your workflows with rapid, precise temperature control that significantly reduces test time and boosts throughput. Whether in R&D or production environments, the Discovery Core Rheometer delivers highly repeatable data that enhances process control, supports regulatory compliance, and drives confident decision-making in pharmaceutical manufacturing.

Empowering Pharmaceutical Scientists with Actionable Rheological Data

The Discovery Core Rheometer allows formulation scientists, process engineers, and QA/QC professionals to:

- Optimize drug delivery systems

- Ensure batch-to-batch consistency

- Predict product performance

- Prevent downstream quality issues

Its seamless combination of technical depth and operational simplicity makes it the ideal rheometer for pharmaceutical labs seeking actionable insights with minimal operator training.

Get Started with the Discovery Core Rheometer

Most pharmaceutical manufacturers aren’t experts in rheology. Their domain expertise lies in high-volume production, not necessarily in the fundamental physics of deformation and flow.

That’s why efficient, adaptable, and easy-to-use instrumentation is critical to accelerate the quality control process. A CDMO that has built a GMP-compliant facility for mass production of a life-saving drug needs high testing throughput and quick onboarding to keep each lot release on schedule.

Looking for a pharmaceutical-grade rheometer that delivers fast, accurate, and reliable measurements for oral suspensions, topical emulsions, and injectables? The Discovery Core Rheometer by TA Instruments | Waters Corporation is your go-to solution for drug development, process optimization, and manufacturing quality control.

Contact TA Instruments today to schedule a demo or request a quote.

Frequently Asked Questions: Discovery Core Rheometer for Pharmaceutical Applications

What is a rheometer, and why is it important in pharmaceutical formulation?

A rheometer is a scientific instrument that measures how materials flow and deform under force. In pharmaceuticals, rheometers help scientists understand formulation behavior—like how a cream spreads, how a suspension stays mixed, or how easily an injectable flows through a syringe. This ensures consistency, efficacy, and user-friendly drug delivery.

What’s the difference between a rheometer and a viscometer?

Viscometers measure only viscosity, typically at one shear rate, while rheometers evaluate viscosity and viscoelastic properties over a range of conditions. Rheometers are ideal for characterizing complex pharmaceutical systems—such as creams, gels, and emulsions—where flow and structural behavior change under stress or temperature.

What rheological tests are used for pharmaceutical formulations?

Key rheology tests for pharmaceutical materials include:

- Viscosity flow curve

- Shear thinning behavior

- Yield stress

- Creep-recovery

- Oscillatory modulus (G’, G”)

- Zero-shear viscosity

These tests predict how a formulation behaves during mixing, storage, application, and administration.

How do you test viscosity of pharmaceutical creams or ointments?

To test semi-solid products like creams or ointments, a rheometer with textured plates is used to prevent sample slip. Tests include flow curves, yield stress, and viscoelastic modulus to understand spreadability, structural stability, and recovery after application. The Discovery Core Rheometer is ideal for this due to its sensitive torque control and advanced testing capabilities.

Can I measure injectables with a rheometer?

Yes, rheometers can simulate high-shear conditions experienced by injectables during syringe delivery. High-shear viscosity and temperature-dependent behavior are key metrics, especially for biologics. The Discovery Core Rheometer provides accurate testing for low-viscosity solutions and high-throughput environments.

How does rheology testing support pharmaceutical quality control?

Rheology testing detects formulation changes that may not appear in visual or chemical analysis—helping to prevent defects, ensure consistency, and optimize performance. Instruments like the Discovery Core Rheometer simplify these tests with automated workflows and rapid results, even in high-volume QC labs.

Is rheology testing difficult to implement in my lab?

Not with the right tools. The Discovery Core Rheometer with RheoGuide™ software enables guided, error-proof testing. It’s built for pharmaceutical labs needing both high-precision R&D and easy-to-use QC workflows. SOP integration and Pass/Fail outputs make implementation seamless.

What types of pharmaceutical products benefit most from rheology testing?

Rheological testing benefits nearly every drug delivery form, including:

- Oral suspensions – to ensure uniform API distribution

- Topical creams/ointments – for texture, spreadability, and recovery

- Injectables – for flow through delivery devices

- Emulsions – for stability over time

- Gels – for structural behavior under stress

Other Resources

- Instrument – Discovery Core Rheometer

- Blog – Viscometer vs Rheometer: Discover Why a Rheometer Offers More Than Just Viscosity Measurement

- Blog – Rheology Theory and Applications

- Application Note – Introduction to Polymer Melt Rheology and Its Application in Polymer Processing

- Application Note – Exploring the Viscoelastic Properties of Cheese Using a Rheometer

- Application Note – Rheological Evaluation of Battery Slurries with Different Graphite Particle Size and Shape

- Contact – Contact TA Instruments Today