Keywords: heat capacity, Cp, DSC, Modulated DSC, MDSC, Quasi-isothermal

TA432

Abstract

Modulated DSC (MDSC®) is an accurate method to measure heat capacity (and specific heat capacity Cp) of materials. Proper experimental conditions are required in order to obtain best results. There are two ways to determine Cp on a Differential Scanning Calorimeter (DSC) using MDSC. One method is to measure Cp over a range of temperature (conventional MDSC); the other provides the opportunity to obtain Cp values at specific temperatures. Calibration is required, but it is easy to set up in the software.

Experimental

The theory of how heat capacity and Cp is calculated using MDSC is discussed in this TA applications note [1], so it will not be discussed here. The two methods that can measure Cp on a DSC using MDSC are described as Conventional MDSC method and Quasi-isothermal MDSC method. The Conventional MDSC method uses a temperature ramp to measure Cp over a range of temperature; the Quasi-isothermal MDSC method measures Cp at specific temperatures. Calibration information for the conventional MDSC method can be found in TA Help for Q Series and in TRIOS Online Help for Discovery Series. Calibration information for the Quasi-isothermal MDSC method will be discussed in the Quasi-isothermal section.

In order to get the most accurate results, pan match is required if the DSC model does not ask for pan mass information in experimental set-up. The mass difference between the reference pan (pan + lid) and the sample pan (pan + lid) should be less than 0.05 mg and masses of pans and samples should be measured accurately for best results.

Ramping – Conventional MDSC

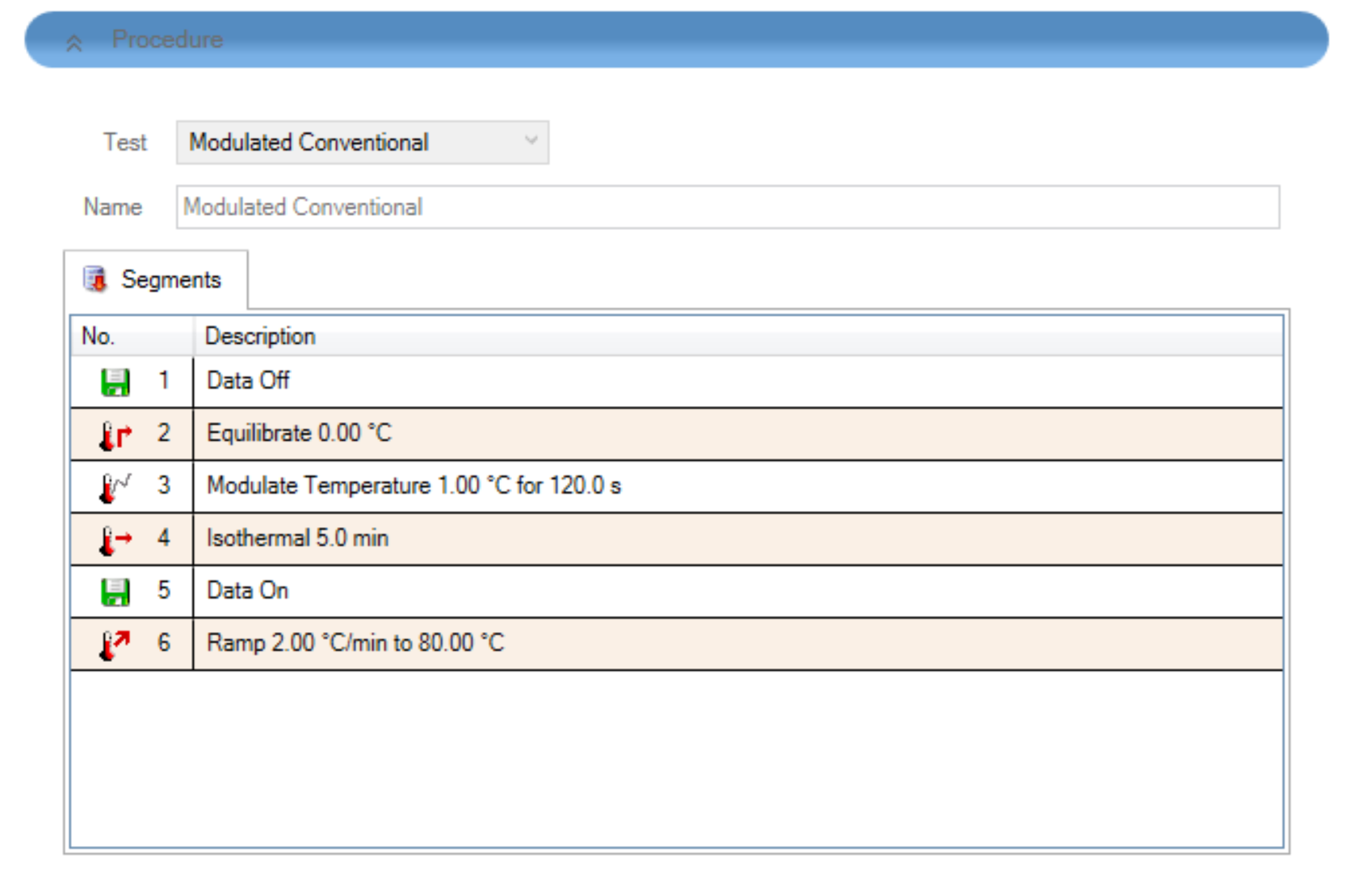

An example on how to set up a test using this method in TRIOS is shown in Figure 1. The set up in Advantage software is the same. First, select a proper temperature range for running this experiment. Then use the parameters recommended to set up the method. Choose Modulated Conventional template or design the method using the procedure stated in Figure 1. The recommended MDSC parameters for this method are:

- Modulation period of 120s

- Modulation amplitude of ±1 °C

- Heating rate of 2-3 °C/min

However, these are optimized for standard and Tzero aluminum pans (hermetic and non-hermetic). If lighter pans or heavier pans are used, please adjust the modulation period accordingly. For instance, when low-mass Tzero aluminum pans are used, the modulation period could be lowered to 100s; when high volume pans are used, the modulation period could be increased to 200s.

Quasi-isothermal MDSC

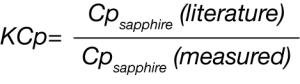

MDSC allows Cp measurements isothermally which standard DSC is not able to do. The experimental set-up using Quasi-isothermal MDSC method is very similar to the Conventional MDSC method. There is a template available in the software. The modulation period and the modulation amplitude are still recommended to be 120s and ±1 °C (adjust these accordingly), but a temperature ramp is not needed. Below is a procedure of this method.

- Amplitude: ±1 °C

- Modulation Period: 120s

- Isothermal Temperature: set to the desired lower temperature

- Isothermal Time: 15min (this is a good starting point)

- Temperature Increment: set to the desired temperature interval; for example, 10 °C.

- Number of Increments: the number of intervals that are needed

An example of this procedure is shown in Figure 2. There is an isothermal step at each temperature. If a single point of measurement is required, the increment step can be removed using the “Custom” template. The specific heat capacity Cp is being measured continuously during isothermal. The Cp value is determined at the last data point of each isothermal step. Before running unknown samples, a calibration test using sapphire is required. One way to calibrate is to run sapphire and calculate a KCp constant at each temperature point using the equation below.

It is important to use the same Quasi-isothermal MDSC® procedure to run sapphire and samples. Another way to calibrate is to do a Reversing Cp calibration same as the calibration for the conventional MDSC method covering the experimental temperature range. MDSC parameters should be kept the same for both calibration and running samples. Two clear sapphire disks are provided in the accessory kit for Cp determination – they are ~20-30 mg. The measured Cp value of unknown samples is obtained at each temperature point and that value multiplying by KCp gives the true specific heat of samples. The calculation is described as below:

Cpsample = Reversing Cpsample (measured) × KCp (2)

Results

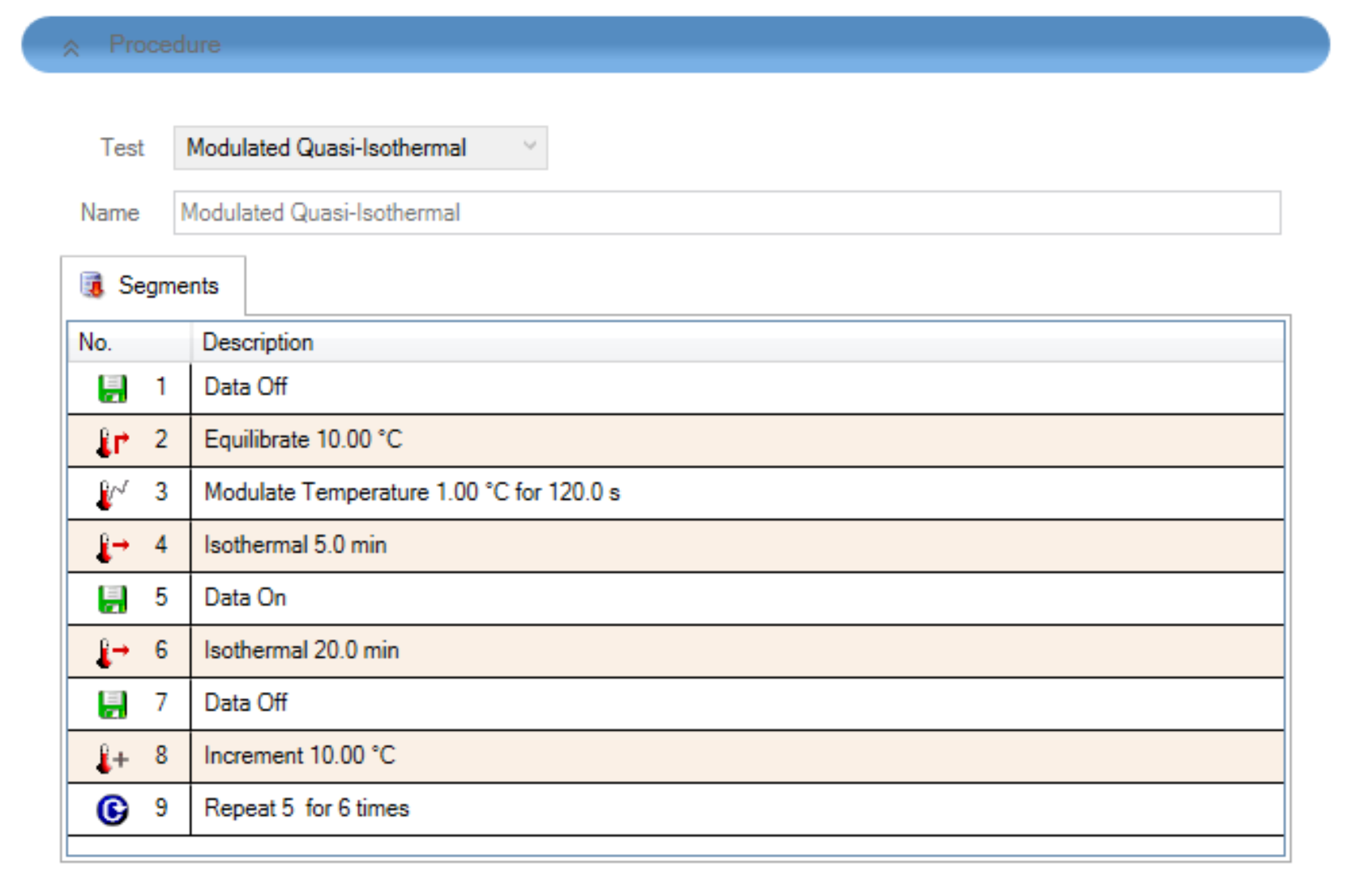

Ramping – Conventional MDSC

A sapphire disk was used to measure its Cp from -50 °C to 150 °C on a calibrated DSC 2500. The Reversing heat capacity (Normalized) is plotted as a function of temperature (see Figure 3). The measured Cp values match with the literature Cp values of sapphire well.

Quasi-isothermal MDSC

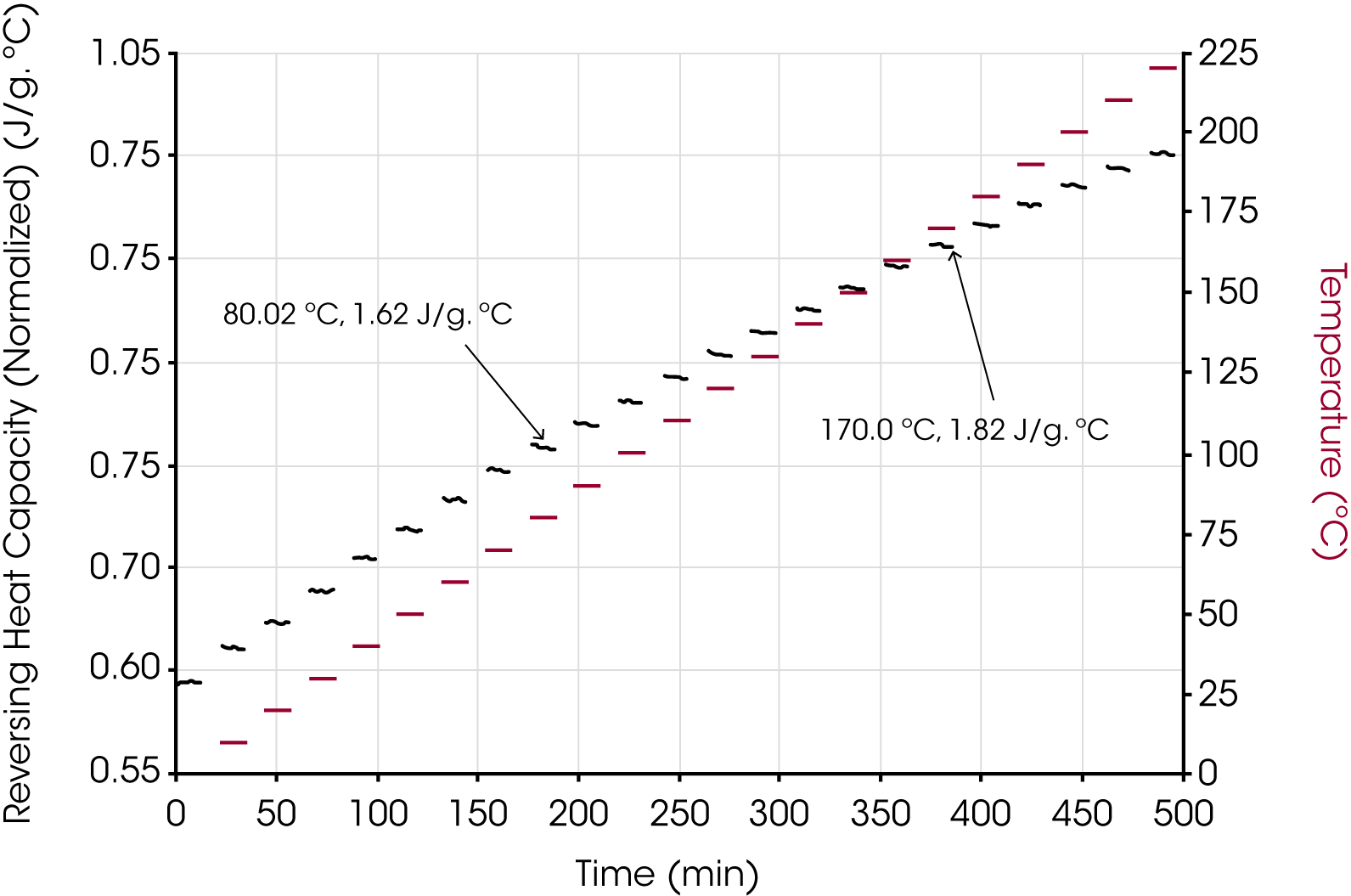

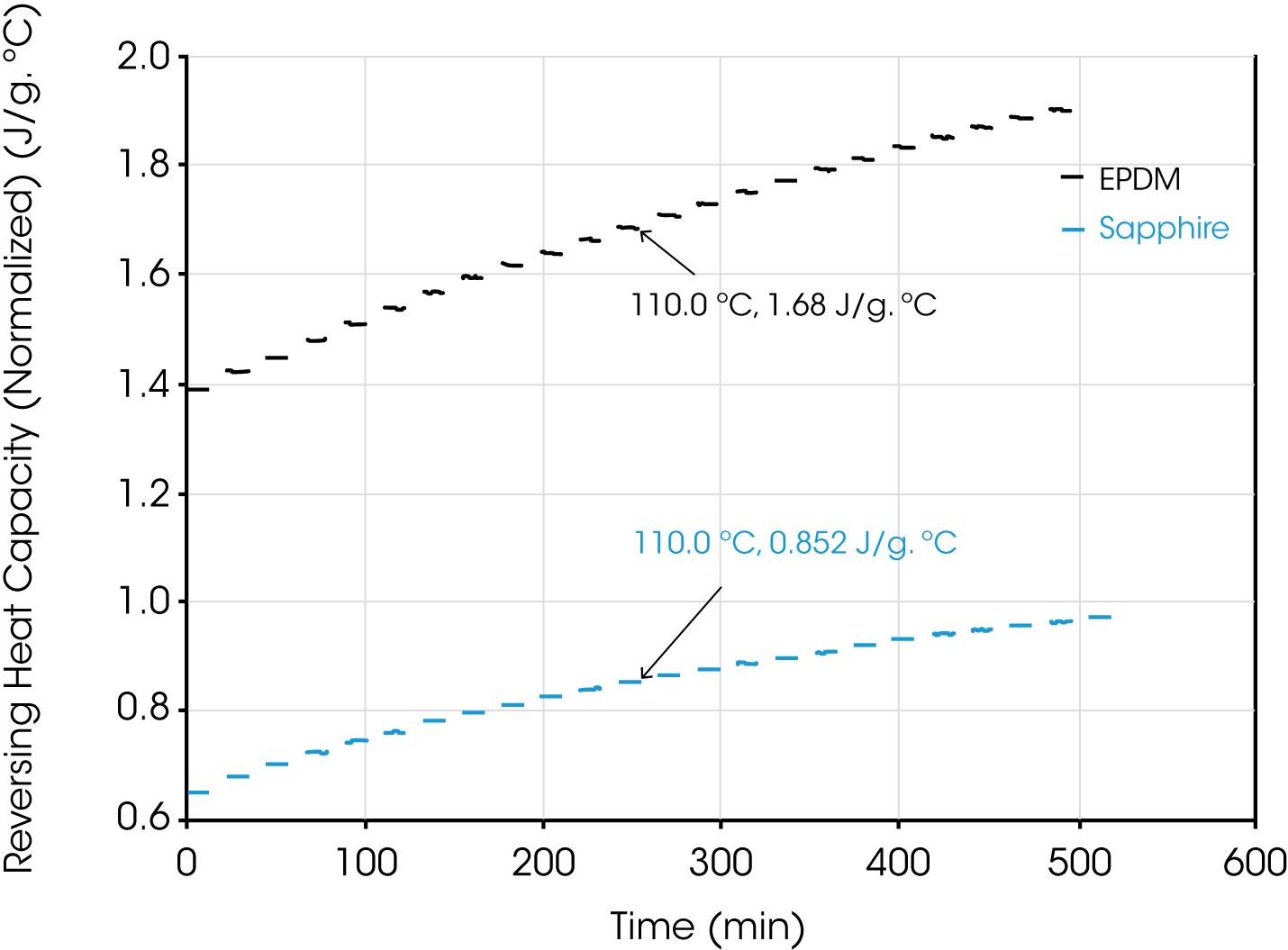

To study the Cp of an EPDM sample at multiple temperatures, a Quasi-isothermal test was done (see Figure 4). The Reversing heat capacity (Normalized) is plotted as a function of time on Y1 axis and the temperature is plotted on Y2 axis. At each isothermal step, a Cp value can be determined. In order to obtain the true Cp of this sample, a sapphire was tested using the same procedure. The Reversing heat capacity (Normalized) data of both materials is shown in Figure 5. At 110 °C, the measured Cp of sapphire is 0.852 J/(g·°C). The literature value of sapphire at this temperature point is 0.922 J/(g·°C) which generates a KCp of 1.08 at 110 °C. The measured Cp of EPDM at this temperature is 1.68 J/(g·°C) so the true Cp of this sample at 110 °C is 1.68×1.08=1.81 J/(g·°C).

Conclusion

In this note, two ways of obtaining specific heat capacity Cp using MDSC on a DSC is discussed. MDSC is a well-established technique for heat capacity and Cp measurements. It is simple and easy to set up in the software. A calibration with sapphire or other standard materials is required prior to running samples. With proper sample preparation and experimental conditions, MDSC can provide accurate and repeatable Cp values.

References

- Modulated DSC Paper #9: Measurement of Accurate Heat Capacity Values, TA Instruments Technical Paper (TP014).

Acknowledgement

This note was written by Yue Schuman, Ph.D., Applications Support Engineer at TA Instruments.

Click here to download the printable version of this application note.