Keywords: Rheology, Chocolate, flow behavior, viscosity, Casson Model, ICA method

RH113

Abstract

The flow behavior of molten chocolate is critical to the chocolate industry. The viscosity and yield stress are the two most important parameters in chocolate manufacturing and applications. In this application note, a TA Instruments Discovery Hybrid Rheometer with the Upper Peltier Plate (UPP) temperature control system and a 40mm sandblasted parallel plate geometry were used for evaluating the flow behavior of 2 dark chocolate samples according to the standard ICA method 46. The sandblasted plate geometry effectively prevents slippage during the viscosity measurements. The Upper Peltier Plate temperature control provides a uniform temperature environment across the sample to ensure the most accurate results. This accessory also significantly reduces the amount of sample that is required for the measurement compared with using the traditional cup/rotor testing geometry. In addition to the standard ICA testing, a steady state flow viscosity evaluation was conducted with a much wider shear rate range from 0.01 s-1 up to 500 s-1. The viscosity curves were analyzed using TRIOS software.

Introduction

Chocolate is a concentrated suspension with particles such as sugar, cocoa and milk suspended in a continuous fat matrix. The rheological properties of molten chocolate are important in food processing for obtaining high-quality products with well-defined texture [1]. Different formulations in chocolate such as fat content, particle size and distribution, moisture or emulsifiers content all have a big influence on the chocolate’s flow behavior [2-3]. Molten chocolate behaves in a non-Newtonian manner with a yield stress. Controlling a desirable viscosity and yield stress in a molten chocolate formulation is critically important in chocolate processing as well as in applications. Over the past years, there have been numerous literature articles that discuss the analysis of rheological properties of molten chocolate using different methods [4-6].

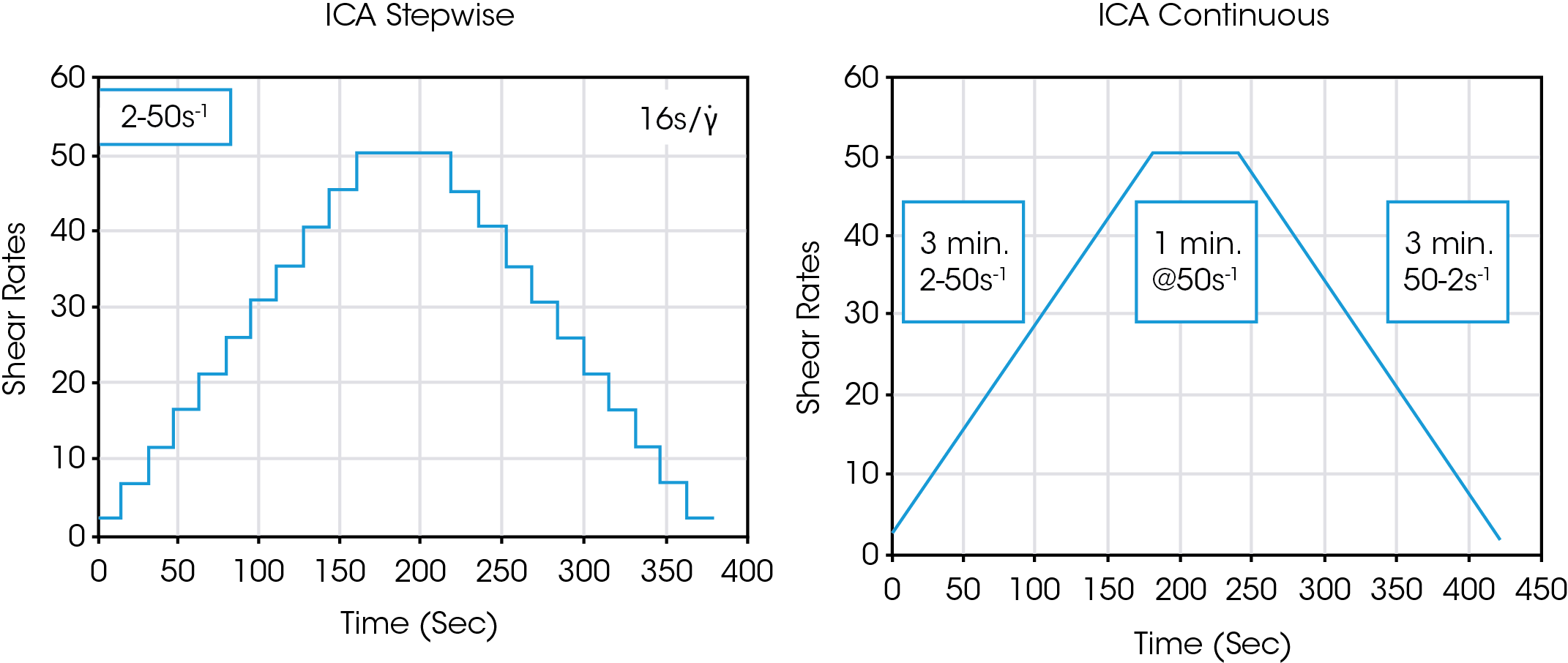

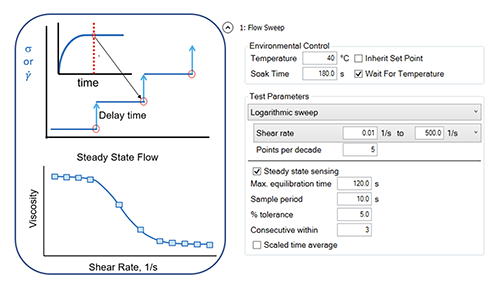

The International Confectionery Association (ICA) introduced a standard method (ICA method 46) for evaluating the viscosity and yield stress of molten chocolate [7]. This standard recommends testing the viscosity of molten chocolate at a temperature of 40 °C. The test procedure can be either a continuous flow ramp from 2-50 s-1 within 3 minutes or a flow step from 2-50 s-1 at 16 seconds per step (Figure 1). Prior to the measurement, the molten chocolate is pre-sheared at 40 °C with a shear rate of 5 s-1 for 5 minutes. The measurement results are then analyzed using the Casson flow model (equation 1).

Where σy is the yield stress and k is the Casson plastic viscosity [5].

√σ=√(σ_y )+ √(kγ). (1)

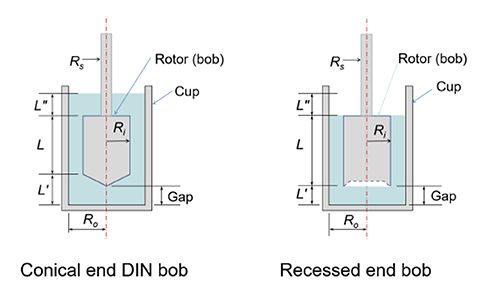

The most commonly used geometries for ICA testing are concentric cylinders with cups and rotors (Figure 2). This cup/rotor device requires large amount of sample and longer temperature equilibration times.

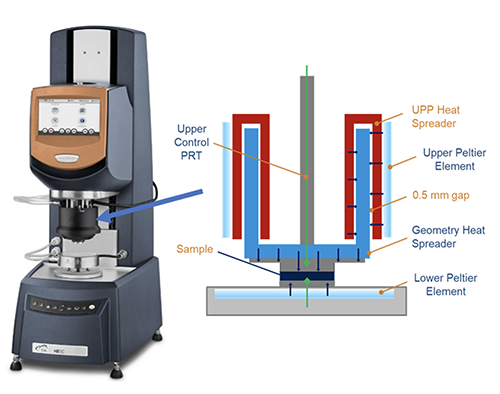

The TA Instruments Discovery Hybrid Rheometer can be equipped with an Upper Peltier Plate (UPP) temperature control system, which is used in combination with the lower Peltier plate (Figure 3). This device provides the most uniform temperature control across the sample. The platinum resistance thermometer (PRT) is placed in direct contact with the testing plate to get the most accurate measure of sample temperature. In this application note, a 40mm sandblasted parallel plate geometry was used in conjunction with the UPP to conduct ICA method 46 testing on 2 molten dark chocolates. The Parallel plate geometry uses much less sample compared with the cup/bob geometry, approximately 1-2mL versus 8-20mL. Also, the sandblasted roughened surface texture helps to effectively prevent sample slippage at the interface.

Experimental

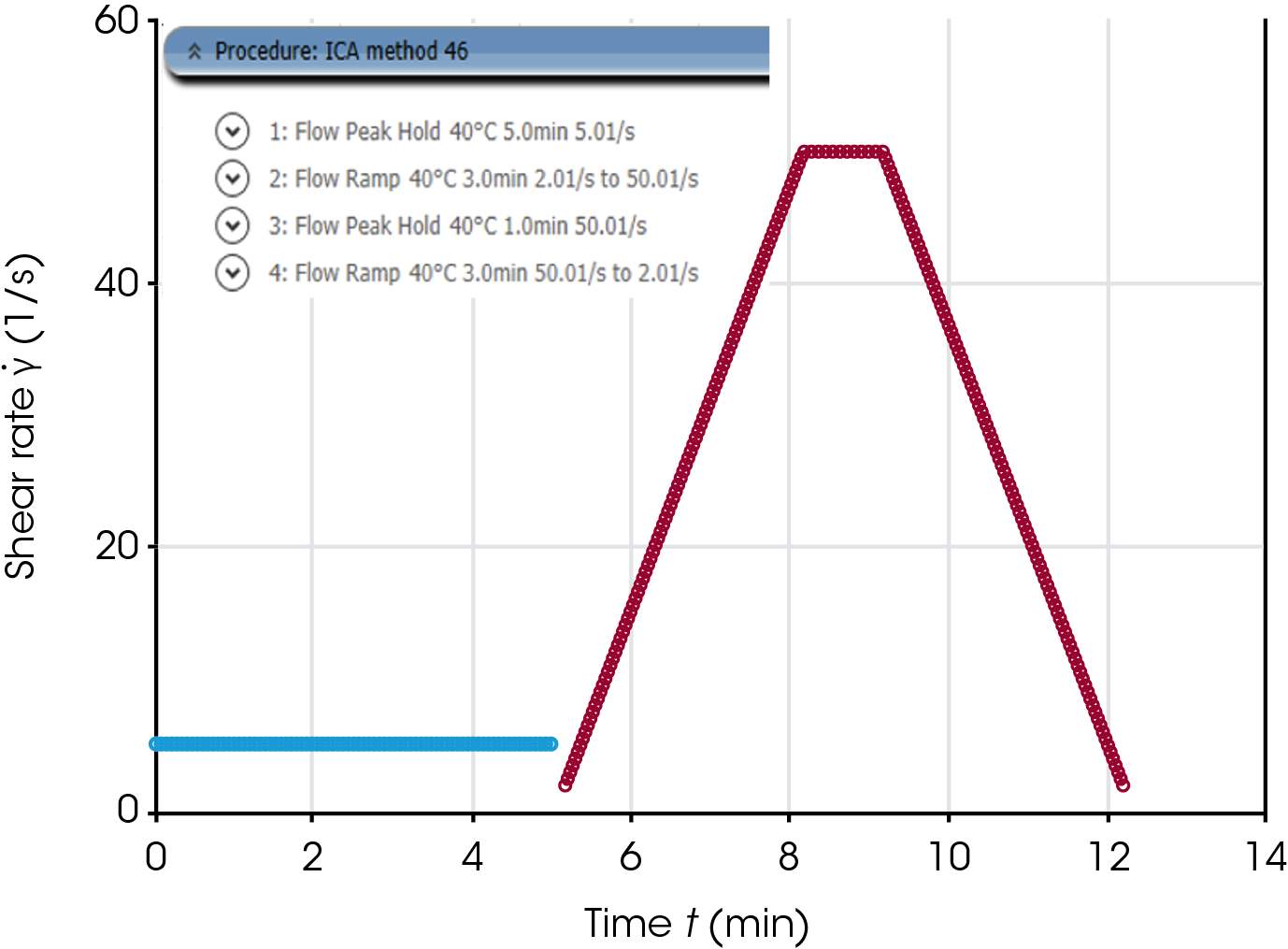

Two dark chocolates with 70% and 95% cocoa content, respectively, were purchased from a grocery store. The samples were equilibrated and pre-melted at 55 °C for one hour before any measurements. A TA Instruments Discovery Hybrid Rheometer with the UPP temperature control system was used for this measurement. The testing geometry was a 40mm sandblasted parallel plate. At a measurement gap of 1mm, the required sample volume is 1.26ml. The ICA method 46 test protocol was translated and programed in TRIOS software and is shown in figure 4. In the first step, molten chocolate was pre-sheared at 40 °C with a shear rate of 5 s-1 for 5 minutes. Then in the second step, the shear rate was ramped up from 2 s -1 to 50 s-1 in 3 minutes. After that, the shear rate was held constant at 50 s-1 for 1 minute. Then in the last step, the shear rate was ramped down from 50 s-1 to 2 s-1 in another 3 minutes. The ICA stepwise method can also be setup in TRIOS and the testing results are identical (data not shown in this apps note).

Results and Discussions

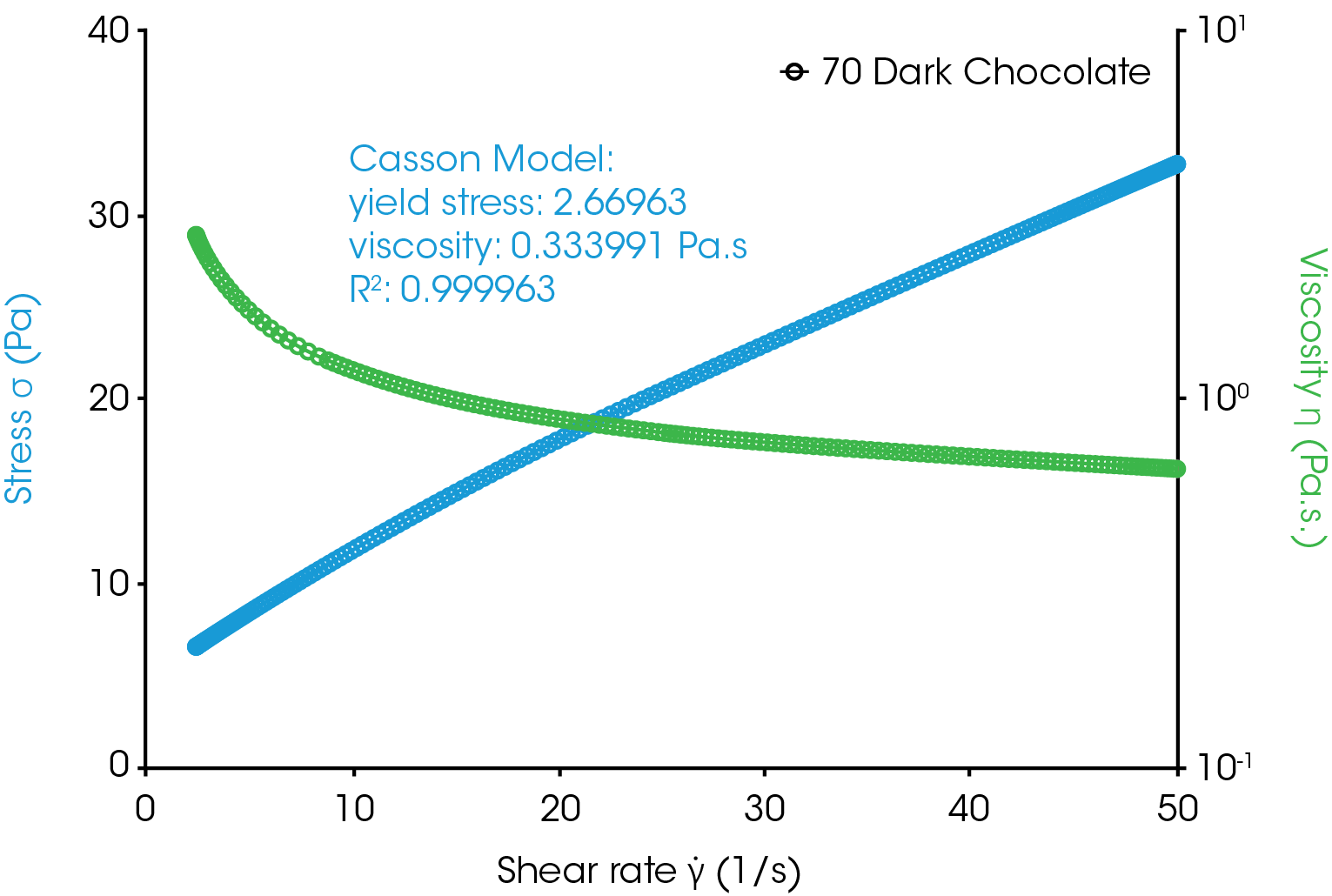

Figure 5 shows the flow ramp up results for dark chocolate with 70% cocoa content. Data are plotted as shear stress versus shear rate and viscosity versus shear rate. The yield stress and Casson plastic viscosity are calculated using TRIOS software by fitting the measurement curve with the Casson model.

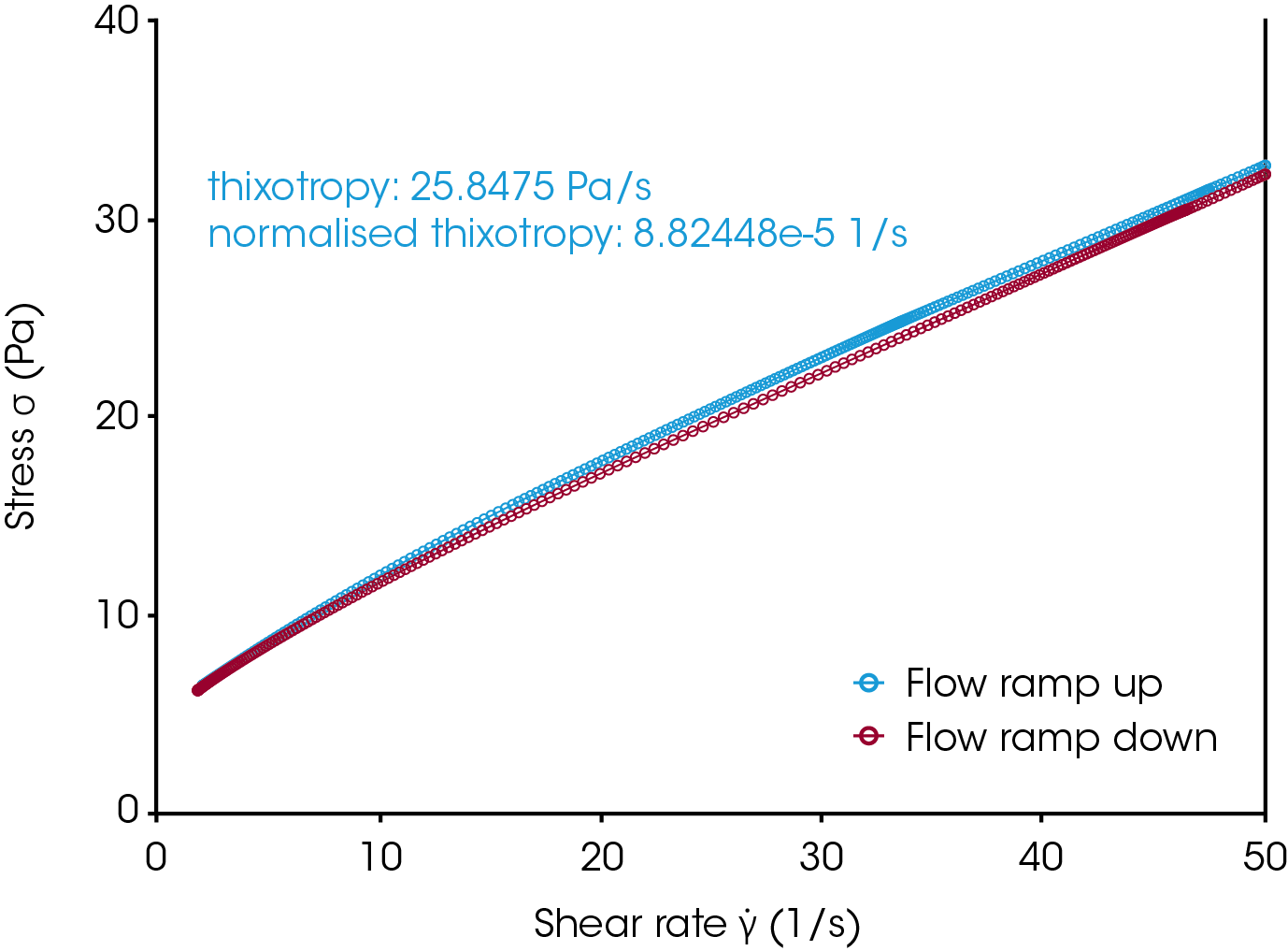

Molten chocolates are thixotropic. Figure 6 shows the overlay results of 70% dark chocolate flow ramp up and down curves according to the ICA method. The flow up and down curves show a hysteresis loop. The thixotropy index is calculated by taking the area between the up and down curves. The normalized thixotropy is defined as the area between the up and down curves divided by the maximum rate, the maximum stress and the step time. This is a better method for comparing thixotropy results obtained from different test conditions. TA Instruments TRIOS software is capable of performing both thixotropy and normalized thixotropy analyses on molten chocolates. The flow test analyses of 2 dark chocolate samples are summarized in Table 1. Results show that the 95% dark chocolate has much lower yield stress and lower viscosity compared with 70% dark chocolate.

Table 1. Flow analysis summary on 2 dark chocolates

| % of Cocoa content | Yield stress (Pa) | Casson viscosity (pa.s) | Normalized thixotropy (10-5 1/s) |

|---|---|---|---|

| 70 | 2.67 | 0.33 | 8.82 |

| 95 | 0.61 | 0.28 | 8.52 |

In recent years, researchers have noticed the limitation of using the ICA test method. First, the recommended shear rate range is limited. Many food processing applications often require the chocolate viscosity information in a much broader shear rate range than the ICA test outlined. The low shear viscosity (e.g. 0.01 s-1) helps correlate to formulation stability, and the high shear viscosity helps guide specific applications needs. Also, even with the stepwise ICA method, the test time at each individual shear rate (i.e. 16 seconds) may not be long enough to ensure that the sample has reached equilibration. This is especially the case when testing high viscosity chocolate formulations under lower shear rates. TA TRIOS software has a steady state sensing algorithm, which helps users to accurately collect steady state equilibration viscosity data with a wide range of shear rate (shown in figure 7).

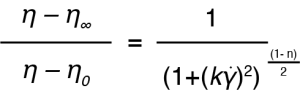

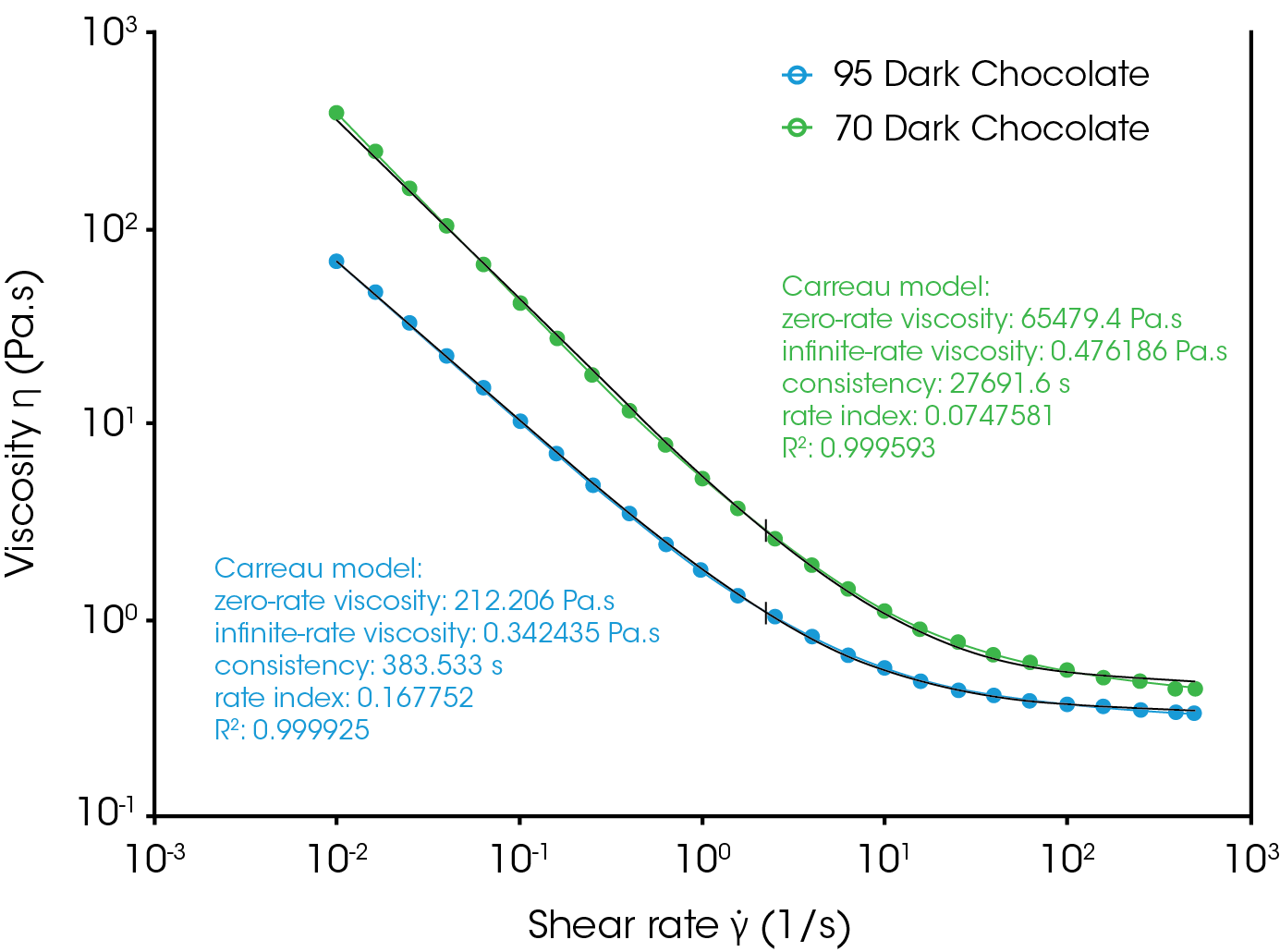

Figure 8 shows the steady state flow test results of 2 dark chocolate samples at shear rates from 0.01 s-1 to 500 s-1. The measurement results fit the Carreau viscosity model well (equation 2).

Where η0 is the zero shear viscosity, η∞ is the infinite rate viscosity, k is the consistency, and n is the rate index. The results show that molten dark chocolate with less cocoa content has higher viscosity and exhibits more shear thinning behavior compared with the chocolate with greater cocoa content.

Conclusions

The flow behavior of molten chocolates can be evaluated using TA Instruments rotational rheometers. The Upper Peltier Plate provides a uniform and accurate measure of temperature for cone-plate and parallel plate measurement. Testing molten chocolate in parallel plate significantly reduces the required sample volume and equilibration time. Also, using a roughened surface sandblasted plate geometry helps to effectively prevent sample slippage at the interface. The standard chocolate viscosity testing method, the ICA method 46, can be programmed in TA TRIOS software. In addition to the ICA method, a broader shear rate range viscosity testing was also conducted, and TRIOS software was able to fit the test results to the most appropriate viscosity model.

References

- Estela Vidal Goncalves, Suzana C.S. Lannes, “Chocolate Rheology”, Food Science and Technology (Campinas), 30(4): 845- 851, 2010. DOI:10.1590/S0101-20612010000400002

- Emmanuel Ohene Afoakwa, Alistair Paterson, Mark Fowler, Joselio Vieira, “Relationship between rheological, textural and melting properties of dark chocolate as influenced by particle size distribution and composition”, Eur Food Technol, 227, 1215-1223, 2008. DOI: 10.1007/s00217-008-0839-5

- ETH Zurich, “Viscosity of cocoa and chocolate products”, Applied Rheology, January, 32-34, 2002.

- Xin Gao, Tongtong Guo, Fei Han, Yu Tian, Zhaohui Zhang, “Rheological and sensory properties of four kinds of dark chocolates”, American Journal of Analytical Chemistry, 6, 1010-1018, 2015.

- Emmanuel Ohene Afoakwa, Alistair Paterson, Mark Fowler and Joselio Vieira, “Comparison of rheological models for determining dark chocolate viscosity”, International Journal of Food Science and Technology 44, 162-176, 2009.

- Veerle De Graef, Frédéric Depypere, Maaike Minnaert, Koen Dewettinck, “Chocolate yield stress as measured by oscillatory rheology”, Food Research International, 44, 2660-2665, 2011.

- “Analytical Method 46 – Viscosity of Cocoa and Chocolate Products “, ICA (2000)

Acknowledgement

This paper was written by Dr. Tianhong (Terri) Chen, Principal Applications Scientist at TA Instruments.

Click here to download the printable version of this application note.