Keywords: cream cheese, viscoelasticity, modulus, yield stress, spreadability, flowability, rheology

RH108

Abstract

Cream cheeses are viscoelastic soft solids. Other than taste, their physical properties such as hardness, viscoelasticity and spreadability are also critical to satisfying consumer’s needs. Rheology is a useful technique that can provide quantitative evaluation of the viscoelastic properties of cream cheese samples. The rheological properties of three different types of cream cheese: Original, Low-fat, and Spread, were measured using a TA Instruments Discovery HR-30 rheometer. The oscillatory frequency sweep test was used to compare the differences in hardness and elasticity. The yield stress of cheese was measured using an oscillatory amplitude sweep. The flowability and spreadability of cheese were estimated using both shear flow and squeeze flow test methods.

Introduction

Cream cheese is a popular food ingredient. Its rheological and textural properties are both important to the consumers’ sensory experience. Cheeses are manufactured from various combinations of milk and cream. The differences in cheese ingredients and processing conditions have big impacts on their final physical properties such as hardness/firmness, elasticity, and spreadability. [1-4]

Many analytical tools such as texture analyzers, hardness testers, and rheometers have been used in characterizing the physical and mechanical properties of cream cheese. Among them, rheological methods are the most frequently used. Rheological testing provides quantitative evaluation of the viscoelastic properties of cream cheese. Rheology can measure the modulus, which correlates to the mechanical strength, elasticity, and yield stress. Rheological measurements can also estimate the flowability and spreadability of cream chesses with different formulations. In this applications note, 3 different type of cream cheeses were measured using a TA Instruments Discovery Hybrid Rheometer.

Experimental

Three commercial cream cheeses, which are identified as Original, Low-fat, and Spread were used in this study. All measurements were conducted using a TA Instruments Discovery HR-30 rheometer with Peltier temperature control system. The test temperature was set isothermally at 10 °C. In order to avoid wall slip during the measurement, a 25 mm and a 40 mm cross-hatched parallel plates were used (picture shown in figure 1). A dynamic frequency sweep test was programmed with a frequency range from 0.1 to 100 rad/s using a strain that is within the linear viscoelastic region (LVR) of the sample. Yield stress was measured using a dynamic amplitude sweep procedure at a frequency of 10 rad/s. The yield stress was measured by taking the onset value of the storage modulus versus stress curve. Cream cheese spreadability was measured using 2 different methods: First, a shear flow test was setup from a shear rate of 0.001 1/s to 10 1/s. During the measurements, edge fracture and slippage were observed at shear rate greater than 1 1/s. Second, a squeeze flow test was performed at a constant linear axial rate of 0.1 mm/s. Sample was loaded to a 25 mm crosshatched parallel plate with an initial gap at about 3 mm. An axial squeeze test was conducted from 3 mm gap down to 1 mm at an axial rate of 0.1mm/s. During the test, shear velocity was locked at 0 rad/s. The axial stress was monitored as a function of time and gap change.

Results and Discussions

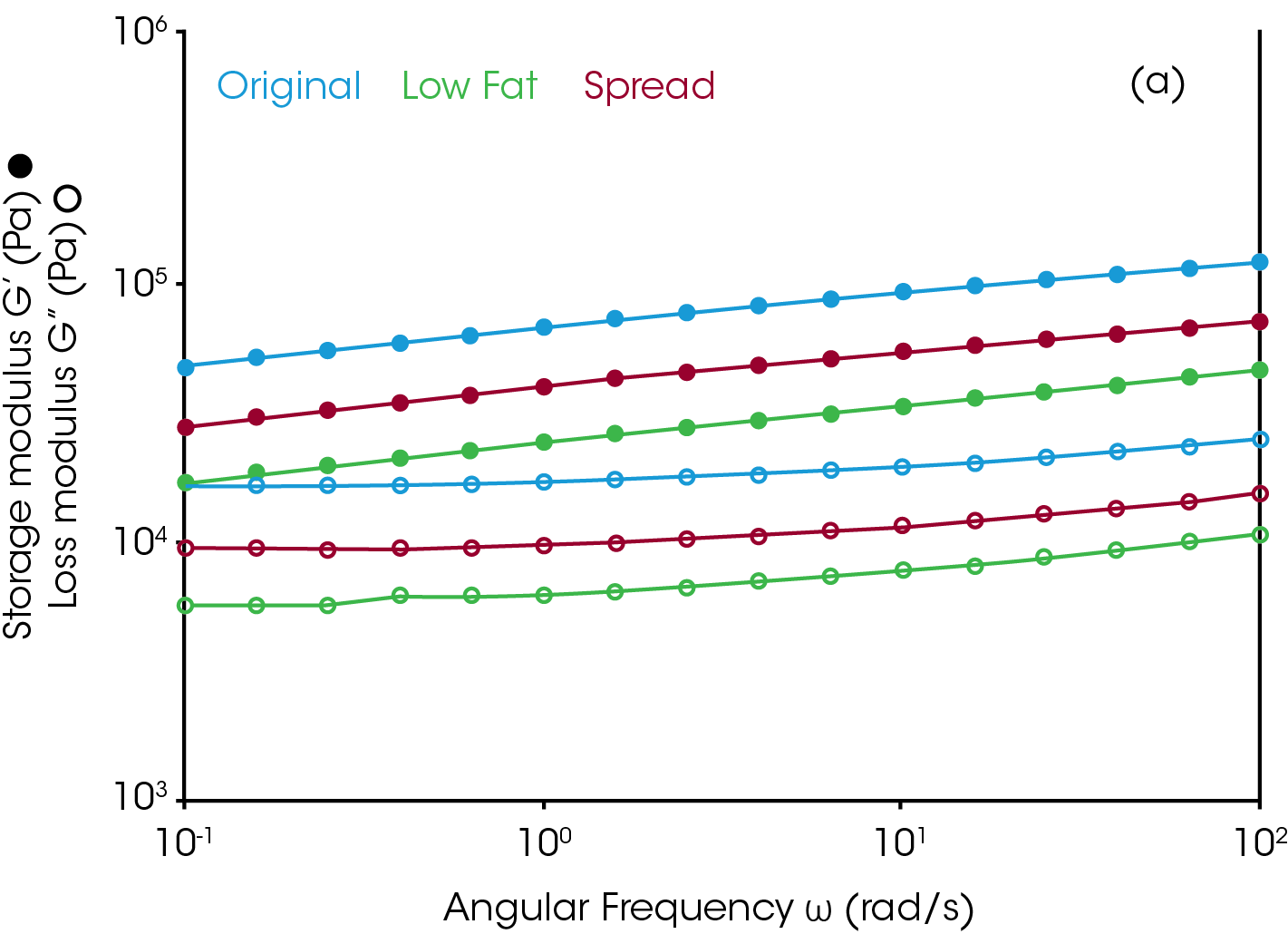

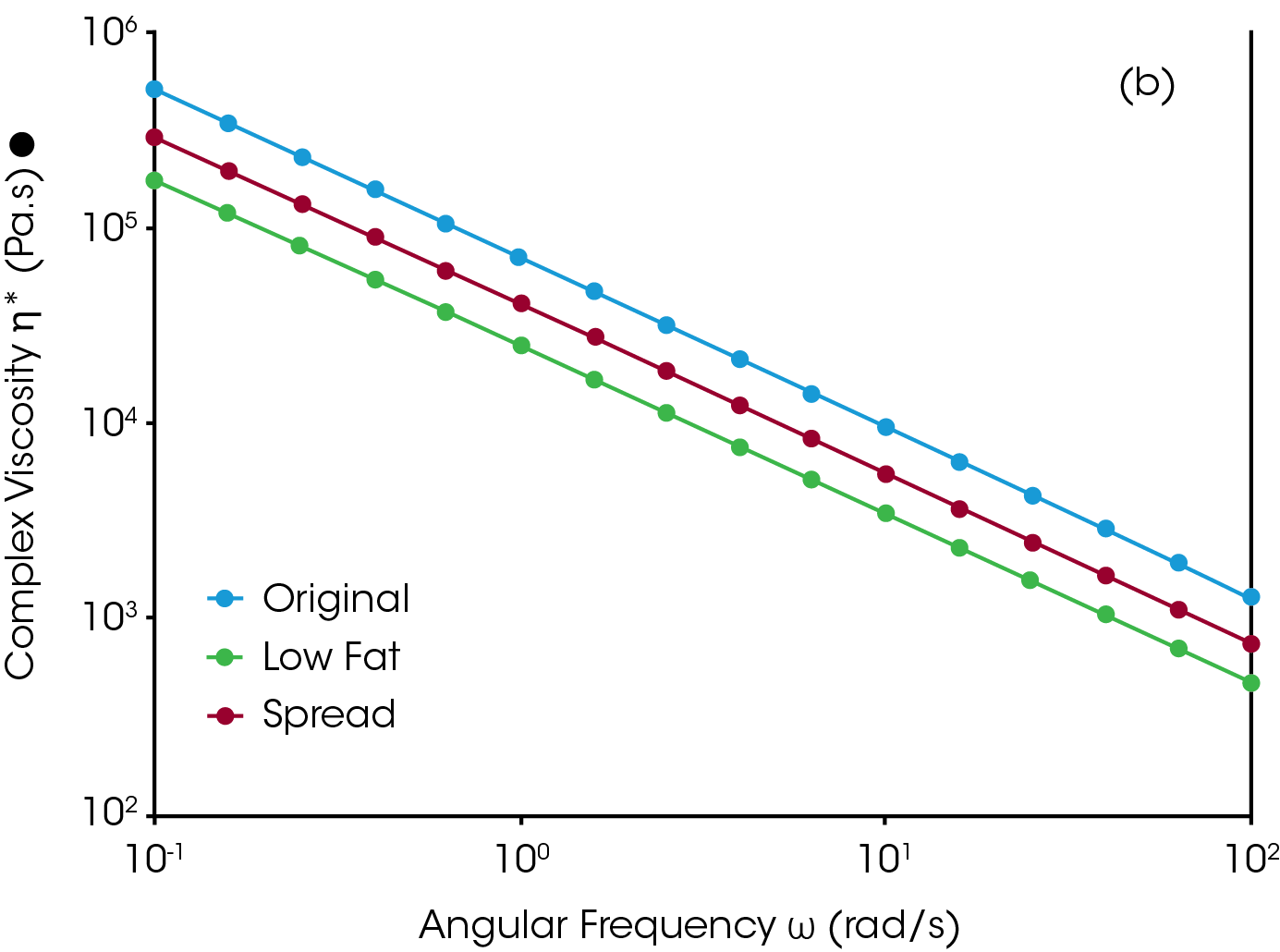

Cream cheese behaves like a soft semi-solid material. Different formulations could cause large variations in their viscoelastic properties. A dynamic frequency sweep test can quantitatively evaluate and compare the differences between different formulations. Figure 2 shows the frequency sweep test results on 3 cream cheeses. For all 3 types of cheeses, within the test frequency range, storage modulus(G’) is always greater than loss modulus (G”) (figure 2a), which indicate that these cheeses are solid-like at this measurement condition (i.e.,10 °C). The storage modulus is a measure of the mechanical strength of the sample, which can correlate to its hardness /firmness. Testing results show that the Original cheese has the highest hardness, and the Low-fat cheese has the lowest hardness among the three cheeses. Figure 2b also compares the differences in their complex viscosity (η*). The results indicate that all three cheeses are extremely shear thinning. Complex viscosity includes two components (equation 1): the viscous component (η’), which correlates to the shear viscosity, and the elastic component (η”), which describes the elastic response of the sample. Since cheese is viscoelastic, the elastic component (η”) also have contributions to the complex viscosity signal. Therefore, this complex viscosity parameter cannot be used to directly correlate to the flowability or spreadability.

η* = η’- ⅈη’’ (1)

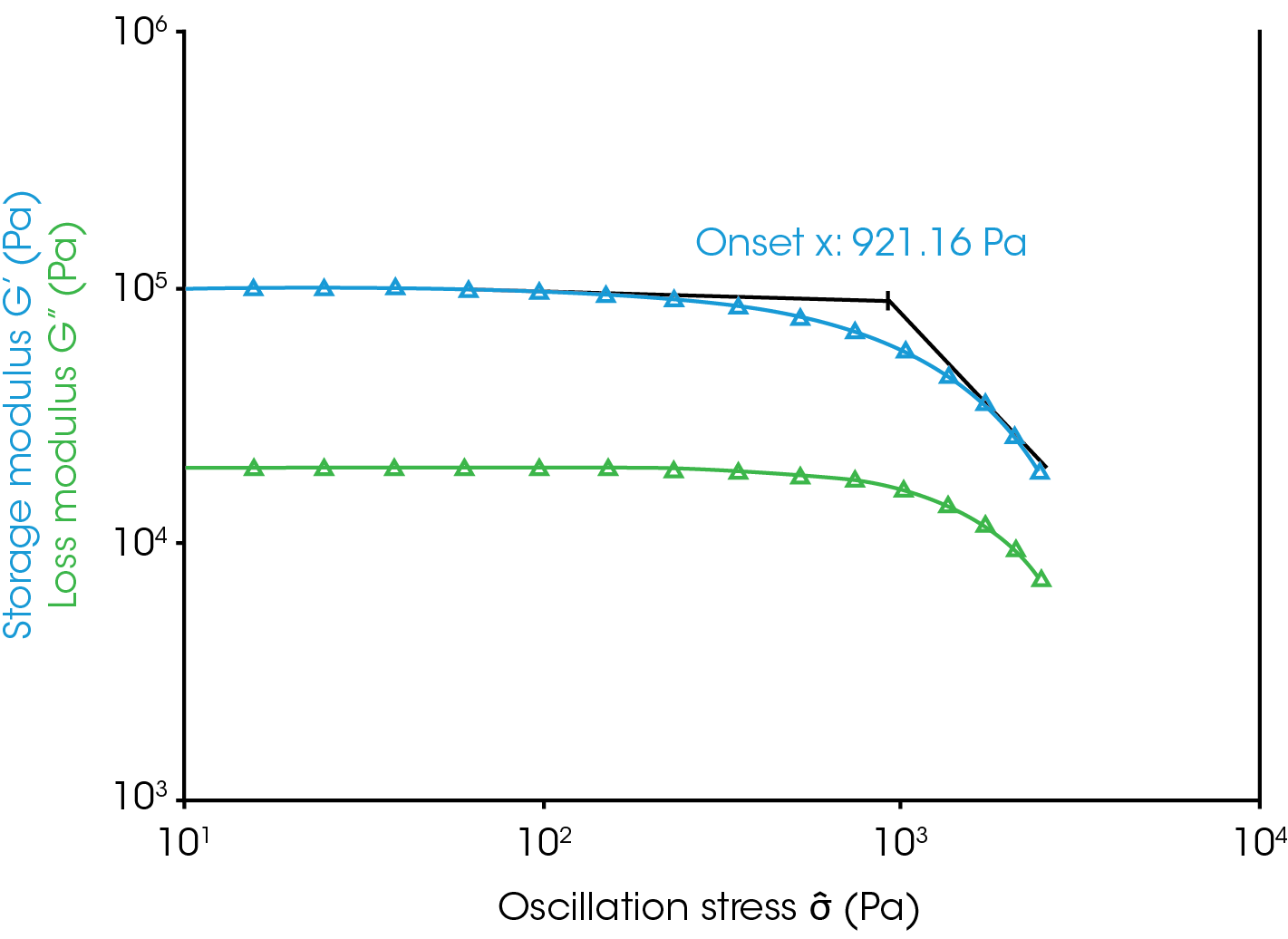

Cream cheese will not flow if the applied stress is below its yield point. Therefore, yield stress analysis is the first step in studying the flowability and spreadability of cheese. There are different rheological methods that can be used to quantitatively describe yield behavior [5-7]. The dynamic oscillatory amplitude sweep test provides the best test reproducibility for analyzing the yield stress of cream cheeses. Figure 3 shows the amplitude sweep result of testing Original cream cheese at 10 °C. Yield can be measured by taking the onset point from the storage modulus (G’) versus oscillation stress curve. Above the yield point, the sample undergoes irreversible plastic deformation. Therefore, this yield point is also described as an indicator of the end of linear viscoelastic region (LVR) of this material.

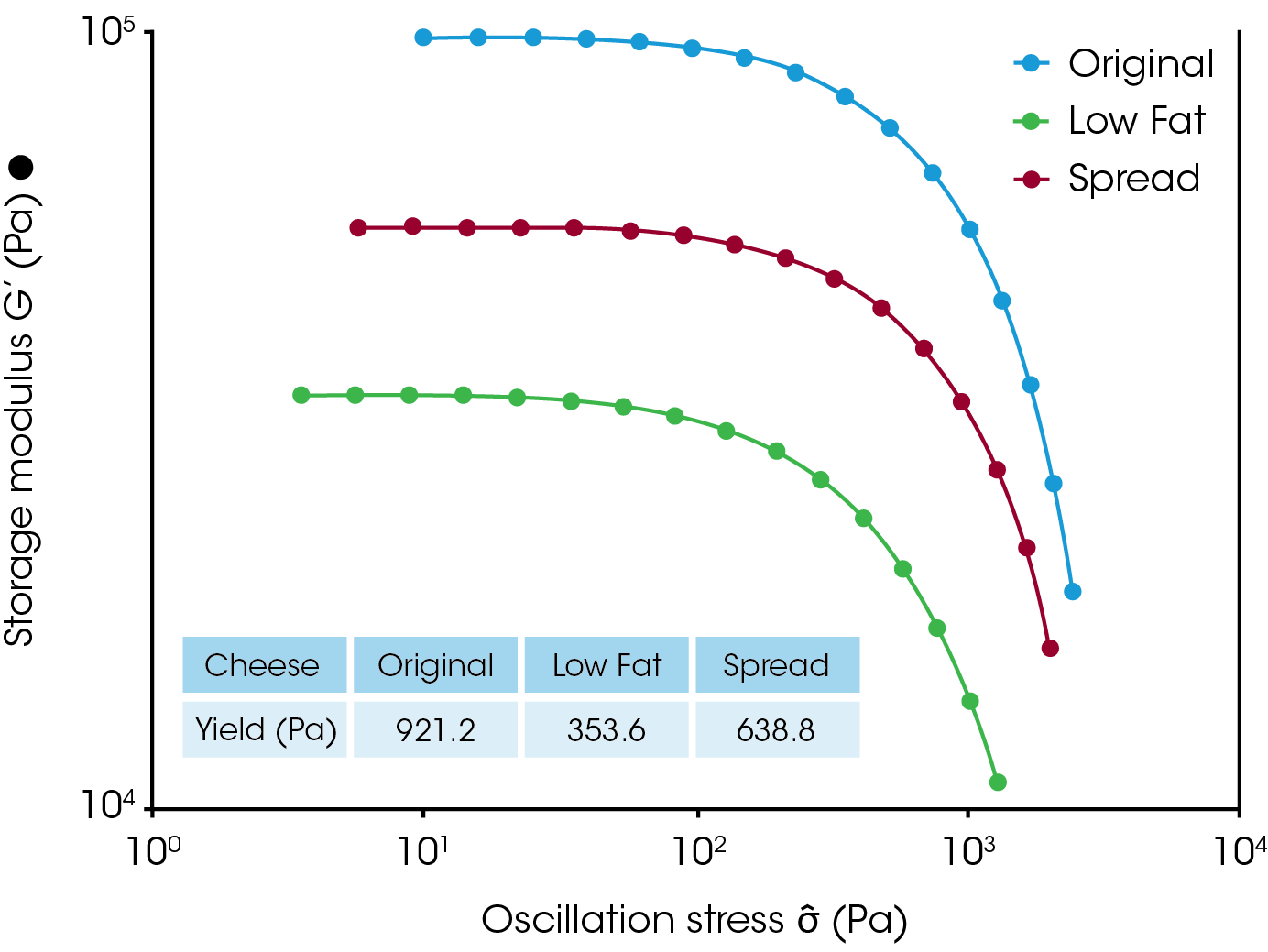

The differences of yield stress on 3 different cream cheeses are summarized in figure 4. Since the Original cream cheese has more fat content, it shows the highest yield stress. The Low-fat cheese shows the lowest yield stress. After the stress exceeds the yield point, the spreadability of cream cheese is typically described by their flow behaviors.

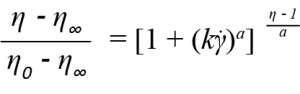

Figure 5 shows the steady shear flow test result on Spread cheese sample. To avoid wall slip, a 40 mm crosshatched parallel plate geometry was used. Even so, samples show obvious slippage at shear rates greater than 1 1/s. This limits the viscosity measurement to the lower shear rate region. However, since this flow curve fits well with the Carreau-Yasuda model (equation 2), one can use model fitting to extrapolate and predict the viscosity at applications condition (e.g. shear rate at 100 1/s).

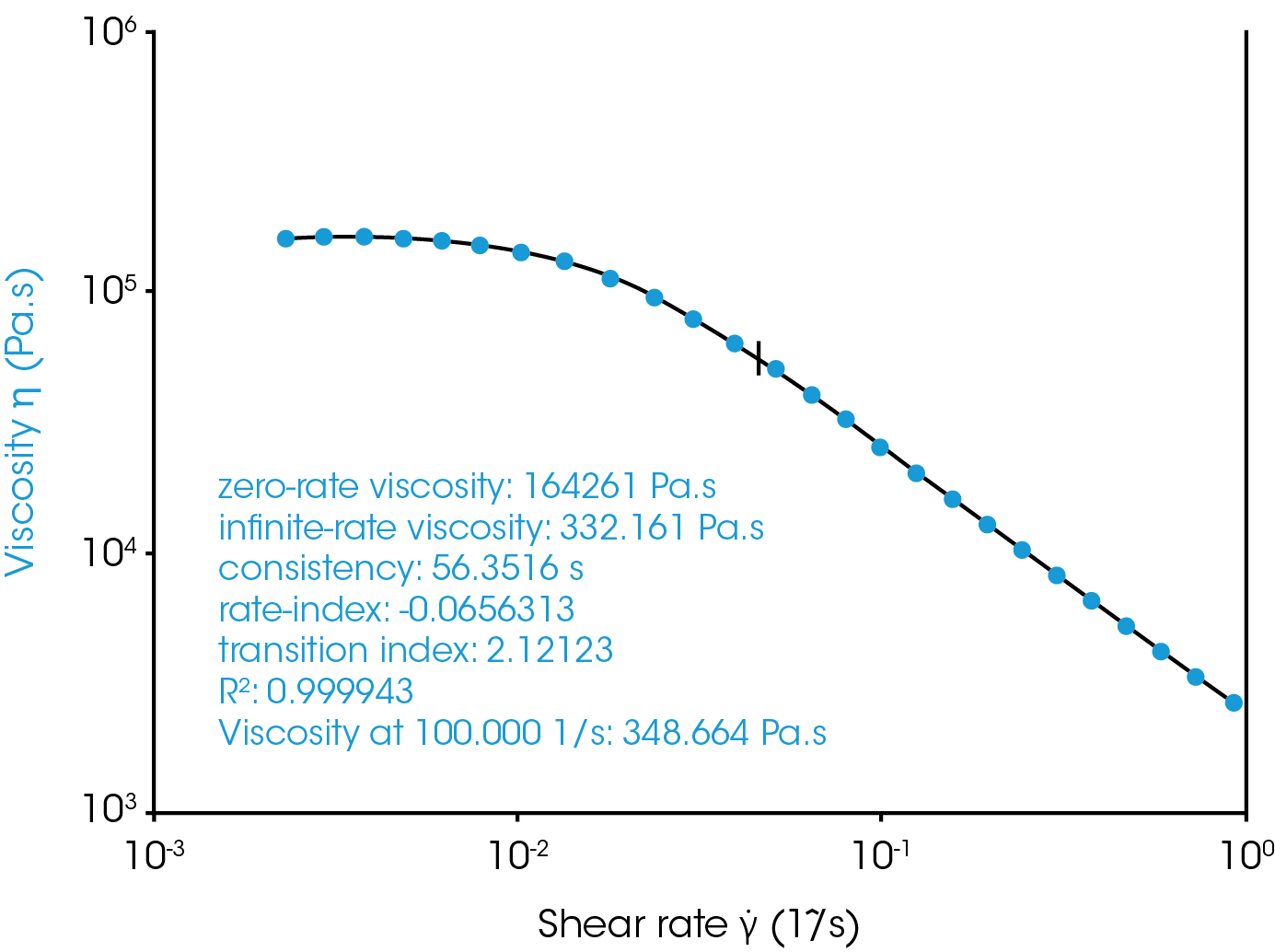

Figure 6 shows the overlay of flow test results on 3 cream cheeses. Above their yield stresses, all 3 types of cream cheeses show significant shear thinning behavior. The shear rate of spreading cheese to the surface of a bread is usually about 10-100 1/s. When extrapolating the viscosity curves to the applications shear conditions, it is obvious that the Spread cream cheese has the lowest shear viscosity, so it is the most spreadable. Even though the Low-fat cheese has a low yield stress and shows lower initial zero shear viscosity, it is less shear thinning. Therefore, the Low-fat cheese has poor spreadability compared to Spread cheese. The original cheese shows the highest predicted viscosity at the spreading shear condition.

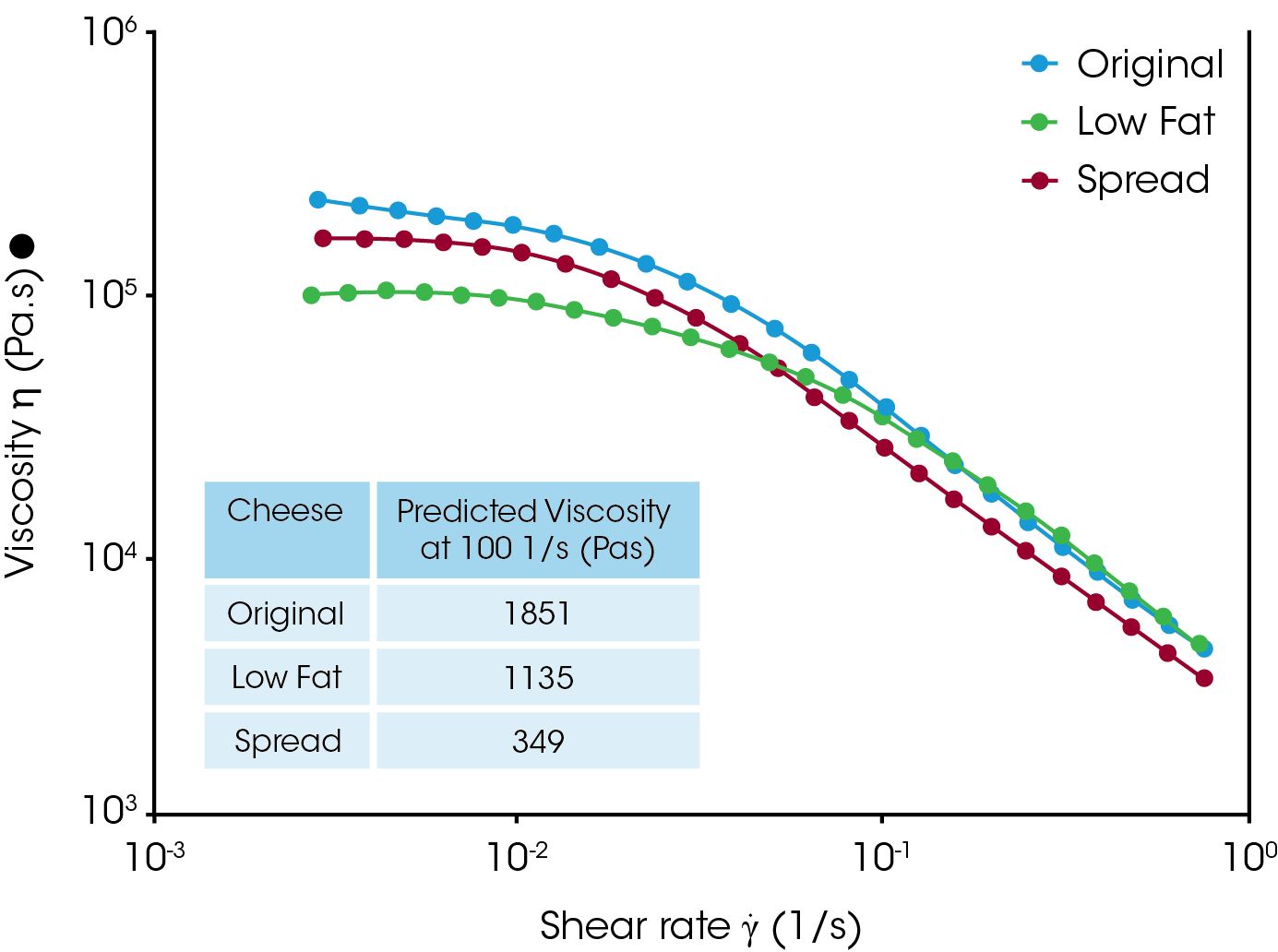

Another method that can be used to measure spreadability is the axial squeeze flow test. The cheese samples were loaded onto a 25 mm crosshatched parallel plate with a gap of 3 mm. Then an axial squeeze flow test was conducted at an axial rate of 0.1 mm/s from an initial gap of 3 mm down to 1 mm. During the test, the axial stress was recorded as a function of time and gap change. Figure 7 shows the squeeze flow test results on the 3 different cream cheeses. The test results clearly differentiate the flowability of these 3 types of cream cheeses. The Spread cheese shows the lowest squeeze flow stress, and it is the most spreadable. Even though the Low-fat cheese has lower modulus (G’), which means it is softer, and it has a lower yield stress, it does not show easy spreadability. In the shear flow test (Figure 6), Low-fat cheese is less shear thinning compared to Spread cheese. In squeeze flow test (Figure 7), the Low-fat cheese also shows much higher squeeze flow stress. Among all 3 types of cheeses, the Original cheese shows the least flowability and spreadability. These shear flow and squeeze flow test methods show good agreement in describing the flow properties of cream cheese.

Conclusions

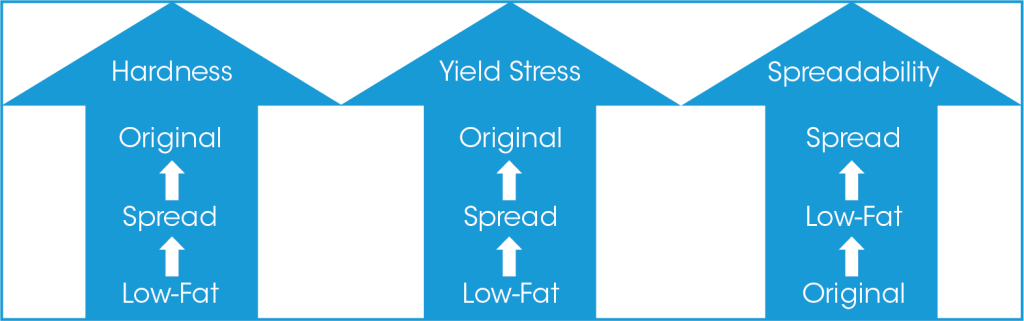

The viscoelasticity and spreadability properties of cream cheeses can be quantitatively evaluated using TA Instruments Discovery Hybrid Rheometer. Based on the analysis results, the Original cream cheese shows the highest hardness, yield stress, and relatively poor spreadability. Since the Low-fat cheese contains less fat, it behaves softer (lower G’) with lower yield stress. However Low-fat cream cheese does not show better spreadability compared to the Spread cheese. The property differences on these 3 types of cream cheeses are summarized in this following schematic.

References

- Bayarri S., Carbonell J., and Costell E. “Viscoelasticity and Texture of Spreadable Cheeses with Different Fat Contents at Refrigeration and Room Temperatures”, J. Dairy Sci. 2012, 95: 6926-6936.

- Breidinger S. L. and Steffe, J. F. “Texture map of cream cheese”, J. Food Sci. 2001, 66, 453-456.

- Geng X., Ipsen R., Liot F., “Rheological Properties of Cold and Hot Filled Model Cream Cheese”, Annual Transaction of The Nordic Rheology Society, 2008, Vol.16

- Brighenti M., Govindasamy-Lucey S., Jaeggi J.J., et al. “Effects of Processing Conditions on the Texture and Rheological Properties of Model Acid Gels and Cream Cheese”, J. Diairy Sci., 2018, 101: 6762-6775

- Franck A, “Understanding Rheology of Structured Fluid”, TA applications note. https://www.tainstruments.com/pdf/literature/AAN016_V1_U_StructFluids.pdf

- Macosko C. W., “Rheology Concepts, Principles and Applications”, 1992, Wiley-VCH.

- Larson R. G., “The Structure and Rheology of Complex Fluids”, 1999, Oxford, University Press, New York.

Acknowledgement

This paper was written by Dr. Tianhong (Terri) Chen, Principal Applications Support Scientist at TA Instruments.

Click here to download the printable version of this application note.