Keywords: ash testing, thermoplastics, food, ASTM E1131, ISO 11358, fillers, glass fiber, inorganic content

TA447

Background

Ash testing is a common technique used to determine the composition of materials. By heating a sample to high temperature in air all organic substances will pyrolyze leaving behind only inert and inorganic substances. This residue is then weighed to determine its weight percentage in the original material. Thermogravimetric Analysis (TGA) is commonly used for this purpose. The following Applications Note discusses this technique along with some typical examples of materials that are analyzed in this manner.

Ash Testing

The most basic form of ash testing involves placing material into a tared crucible and then into a furnace at high temperature. Weights are recorded before and after the sample is heated to determine inorganic weight percentage. ASTM D5630 and E1755 correspond to this furnace method for plastic and biomass samples, respectively. An advantage of this method is that relatively large samples can be tested, reducing error due to sample heterogeneity. Alternatively, TGA is an instrument designed to measure the weight of a sample vs. temperature, with the ability to easily and precisely reach temperatures needed to fully pyrolyze organic content. TGA is widely available in many industrial and research settings, making it convenient for ash testing. TGA instruments are also often equipped with autosamplers and record data electronically, which allows simple, high throughput, and real time ash data collection. The tradeoff with this method is smaller sample sizes (often only a few pellets vs. 2g-10g of material in the crucible method), however this is generally not an issue for homogenous materials and replicate testing can reduce error. Ash content by TGA is specified in the methods ASTM E1131 and ISO 11358.

Ash Testing of Reinforced Polymers

Polymers are often formulated with inert fillers to improve mechanical or other properties. One common example of this is glass reinforced thermoplastics. Thermoplastics are compounded using extrusion, with the filler content controlled by a feeder set to the appropriate rate. An important quality control check for these materials is ash testing to verify that the actual level of filler matches the set level. A mismatch between measured and set filler content indicates an issue in the process, such as a feeder not feeding material at the correct rate.

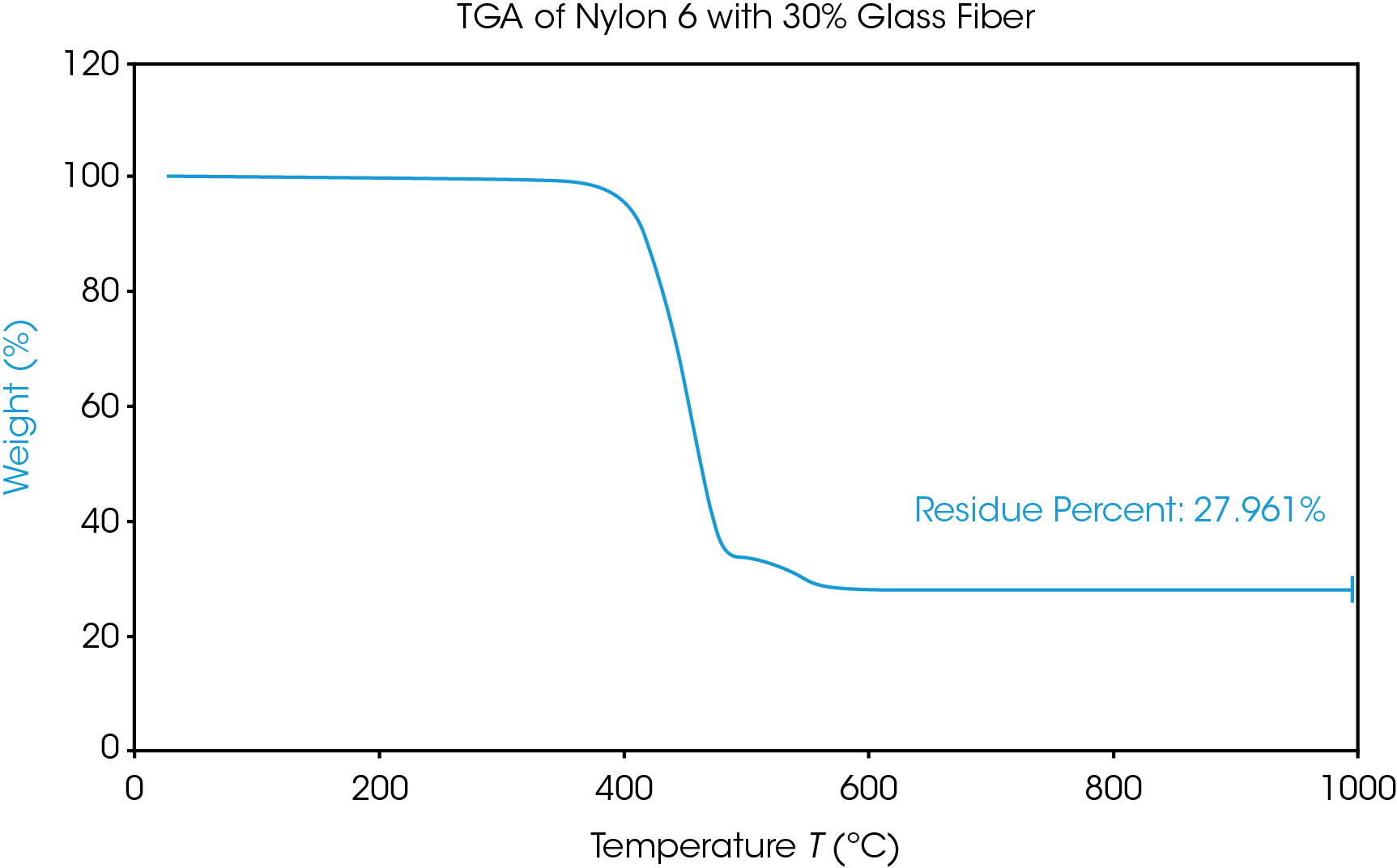

Figure 1 gives the results of a routine ash test on a glass filled polymer. Nylon 6 with 30% by weight glass fiber (PA6 + 30% GF) was tested using a TA Instruments Discovery TGA 5500. The following method was used:

- Set purge gas to air

- Ramp at 20 °C/min to 1000 °C

A final testing temperature of 1000 °C is not necessary for many materials, but the temperature should exceed the point where weight loss stabilizes and the weight signal reaches a plateau.

TA Instruments TRIOS software was used to analyze this data, using the “residue” analysis feature. The result of a representative TGA test of this material is presented in Figure 1, along with statistics for five total replicates. The measured residue at 1000 °C is about 2% lower than the stated value of 30% glass fiber loading. This may be within the process limits for this material but may also be a large enough deviation to affect mechanical properties.

| 1 | 2 | 3 | 4 | 5 | Average |

|---|---|---|---|---|---|

| 28.124 | 27.961 | 27.864 | 27.889 | 27.798 | 27.927 ± 0.125 |

Ash Testing of Food Products

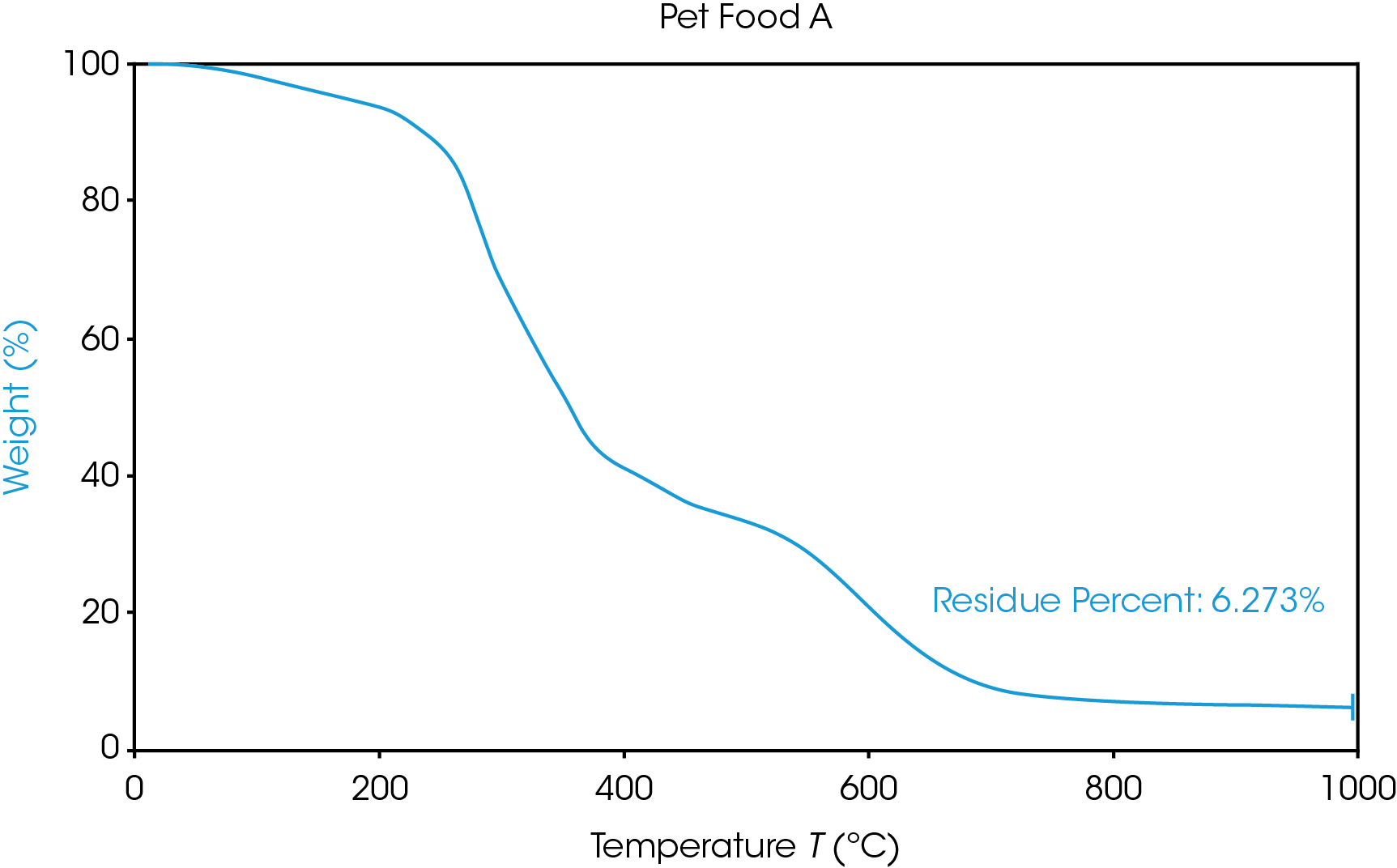

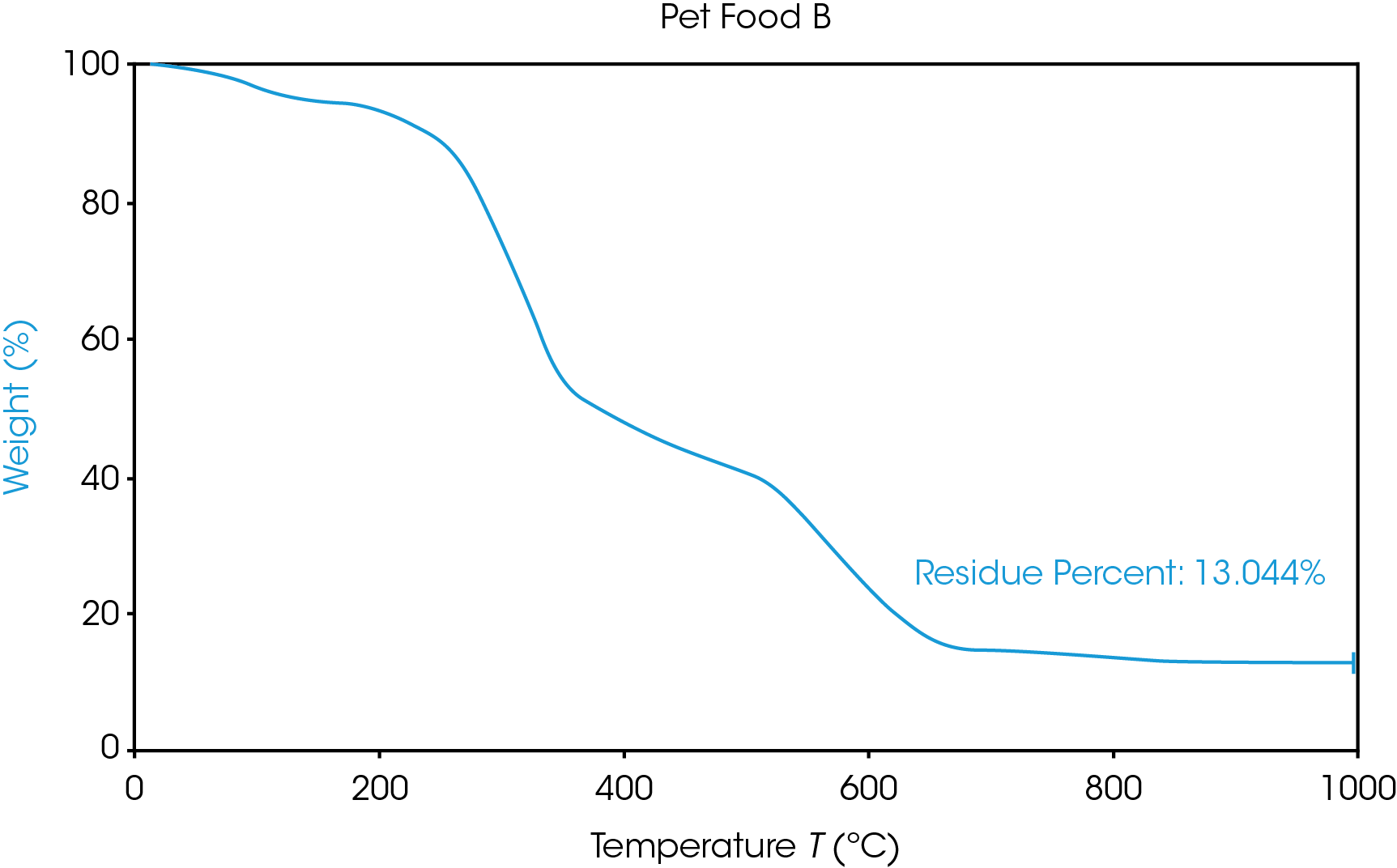

Ash level is also a commonly reported parameter for many food products, especially processed/formulated products such as pet food. This is often reported as a maximum ash level on a product’s label. This number gives a non-specific indication of the inorganic content in the product. Depending on the context, this number can be important for understanding mineral nutrient content. It can also reflect the quality of food in some cases, as low-quality foods may be formulated with excessive amounts of inexpensive fillers such as bone and cartilage.1

Figure 2 gives the results of ash testing of two commercially available pet foods, designated Pet Food A and Pet Food B. The packaging of both samples had ash content reported on the nutritional labels. The same method as above was used. Five replicates were performed on each pet food. The results aligned well with the nutritional labels, with both pet foods giving ash results below the maximum stated levels.

| Test Number | Pet Food A | Pet Food B |

|---|---|---|

| 1 | 6.273 | 13.044 |

| 2 | 6.053 | 13.129 |

| 3 | 6.223 | 13.285 |

| 4 | 6.367 | 13.214 |

| 5 | 6.054 | 13.109 |

| Average Std. Dev. | 6.194 | 13.156 |

| 0.138 | 0.094 | |

| Maximum Ash (from nutritional label) | 7.66% | 18% |

Conclusion

Ash testing is a well-known application of TGA for measuring precise levels of inorganic content in materials. This technique is widely used as a quality control tool for formulated products, as well as in other applications where the level of filler/inorganic content must be quantified. This Applications Note demonstrated a simple TGA method that can be used to measure ash content of plastic and food products.

References

- The Importance of Ash Level in Pet Food; https://be.chewy. com/importance-ash-level-pet-food/, accessed 10/25/2021

- ASTM E1131-20, “Standard Test Method for Compositional Analysis by Thermogravimetry”; https://www.astm.org/Standards/E1131

- ISO Standard 11358-1:2014, “Plastics – Thermogravimetry (TG) of polymers”; https://www.iso.org/standard/59710.html

Acknowledgement

This paper was written by Jeffrey Marvin, Applications Engineer at TA Instruments.

Click here to download the printable version of this application note.