Polymer additives enhance resin properties and add value by tailoring it for specific applications. Compounders and masterbatchers combine neat resins with appropriate combination of stabilizers, compatibilizers, antioxidants, or colorants to produce process-ready formulations. Such pre-formulated compounds can be directly processed by converters; alternatively, concentrated masterbatches offer a flexible, cost-effective option for dispensing additives since they are let down with the base resin during processing.

Additive manufacturers, compounders and masterbatchers use polymer characterization to get a thorough understanding of the incoming resin’s properties, evaluate how they are modified by their additives, and ensure that it can be processed correctly by their customers.

Instruments and Test Parameters

Differential Scanning Calorimetry

Phase transition

- Melting temperature (Tm)

- Heat of fusion

- Glass transition (Tg)

- Crystallinity

Thermal stability

- Oxidative Induction Time (OIT)

- Oxidative Onset Time (OOT)

Polymer Workflow Automation

Thermal stability

- Decomposition temperature

Composition determination

- Volatile or solvent content

- Filler content (residue)

Polymer Workflow Automation

Processability

- Viscosity flow curve

- Zero shear viscosity

- Viscoelastic properties (Storage modulus, loss modulus)

- Crossover modulus and frequency

Polymer Melt Rheology Workflow Automation

Powder behavior during processing

Mechanical properties of materials

- Storage modulus, loss modulus, tan delta

Application Examples

What is the processing temperature for this resin?

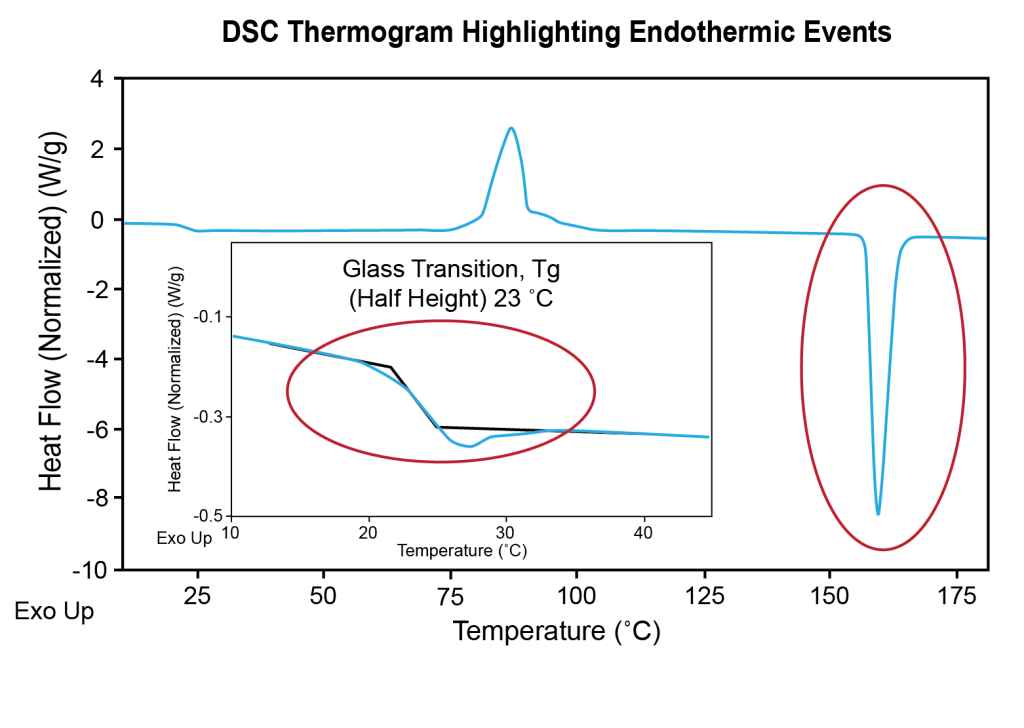

Understanding the temperatures at which polymers soften and melt is a fundamental material property relevant to polymer processing. As one of the first steps in extrusion, injection molding and film blow molding processes, resin pellets are routinely heated past the melting point; for thermoforming and blow molding, the resin is heated above its glass transition temperature to soften it, but without completely melting it. This transformation from a solid resin pellet (lower energy state) to a softened or completely melted pellet (higher energy state) requires the input of energy and can be measured using Differential Scanning Calorimetry (DSC).

In a DSC test, the heat flow of the sample is monitored as the temperature is increased at a constant rate. Thermal transitions such as melting and glass transition show up as endothermic events, where the material absorbs heat as it moves into the higher energy state. The results also reveal information about the polymer morphology, with clear differences between amorphous and semi-crystalline states. During a DSC test’s first heat cycle, amorphous materials display a broad glass transition without melting, while semi-crystalline polymers have a sharp and well-defined melting peak. Since the melting and glass transition temperatures are unique to each polymer, this information can be used to quickly evaluate the quality of the incoming feedstock prior to processing.

Answer the following questions with results from your DSC:

- Feedstock evaluation: Is this a neat polymer, or is it a blend? Can vendor A’s resin be replaced with lower cost resin from vendor B?

- Processing: How much thermal energy is needed to completely melt the resin pellets?

- After processing: Is there a thermal history after processing vs. as-received? (1st vs. 2nd heat)

- End-of-life recycling: Does this batch of PCR (post-consumer resin) have significant contamination from other polymers?

How stable is this resin during processing and end-use?

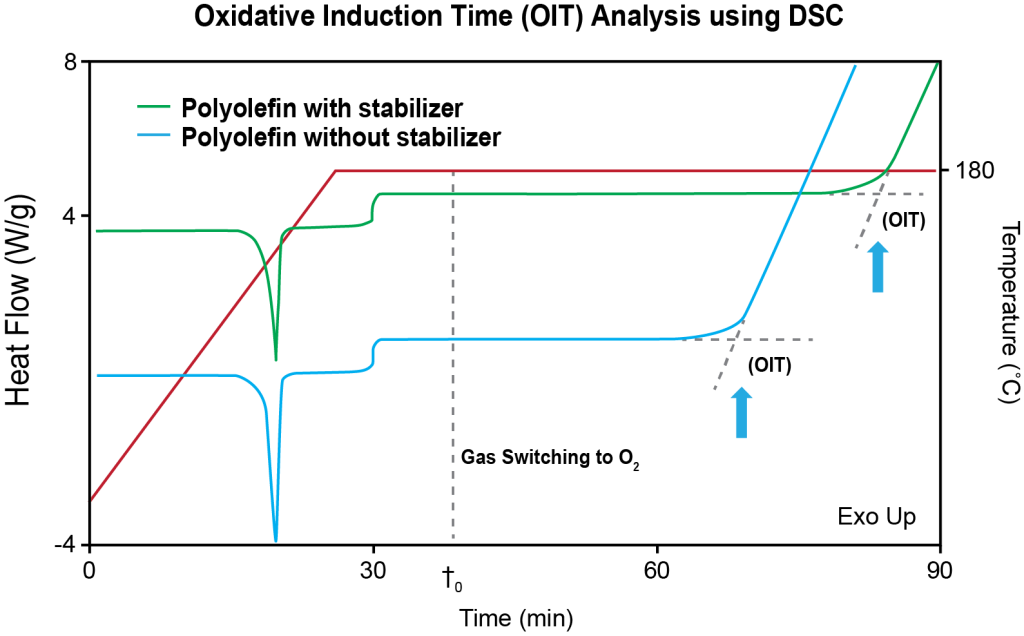

Stabilizers and other additives are often added to resins to prevent degradation from environmental effects encountered during processing and end-use conditions. These additives include antioxidants, oxygen scavengers, heat and UV light stabilizers, or flame retardants, to ensure the polymer’s intended properties are maintained during processing and the product’s lifetime. Stabilizers are inherently sacrificial and are gradually consumed when exposed to high temperature or UV light; once the stabilizer is completely exhausted, the polymer properties start to degrade rapidly.

The performance of stabilizers can be evaluated through Oxidative Induction Time (OIT) analysis on the DSC. In this isothermal test, the purge gas in the DSC is switched from Nitrogen to Oxygen, providing an environment where the stabilizer is consumed. At the onset of polymer degradation, the heat flow signal starts to increase and the time is noted as OIT.

Temperature ramps on the DSC can also be used to measure the Oxidative Onset Time (OOT), a related measure of polymer stability. Both OIT and OOT tests can also be performed using a high-pressure DSC, which reduces test time by accelerating stabilizer consumption.

Answer the following questions with OIT & OOT results from your DSC:

- Feedstock evaluation: Can this resin be processed as-is? Are antioxidants needed for additional stability?

- Failure Analysis: Did this part antioxidant at sufficient levels suitable for the end-use conditions?

- End-of-Life recycling: How much antioxidant is needed to stabilize and process this batch of PCR?

Related Application Notes:

How does this resin flow?

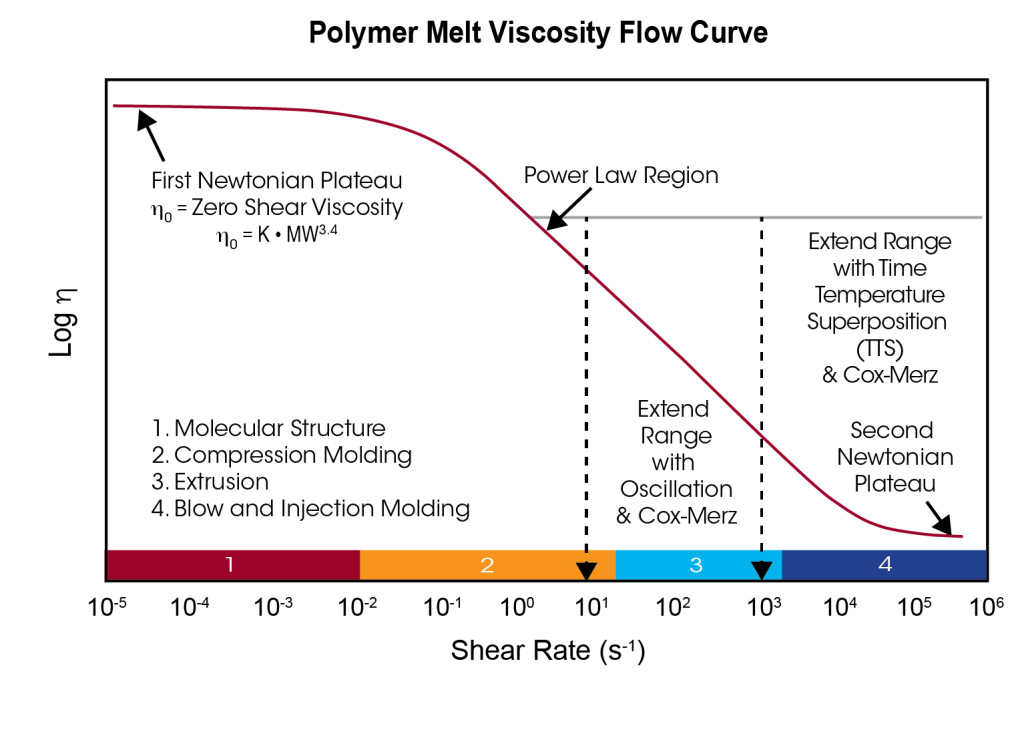

The viscosity and viscoelastic behavior of polymer melts plays an important role when processing polymers using injection molding and extrusion techniques. At a basic level, the viscosity represents the material’s internal resistance to flow – resins with higher viscosity flow slower and take more time to fill the mold, increasing the cycle time and introducing the possibility of defects like short shots. As a result, it is critical to measure and carefully control the viscosity of the resin to ensure process stability and eliminate batch-to-batch variations.

For polymer melts, the viscosity profile depends on the rate of deformation, also known as the shear rate. At the high shear rates encountered in the extrusion and injection molding processes, the viscosity curve displays a shear-thinning behavior in the power law region – as the shear rate increases, the viscosity decreases. This shear rate dependence is influenced by the polymer’s molecular weight distribution and degree of branching.

While high shear rates are relevant to processing conditions, viscosity measurements at low shear rates are essential for revealing the resin’s molecular structure. The zero shear viscosity in the first Newtonian plateau directly correlates with resin’s molecular weight, and can be measured using rotational rheometers.

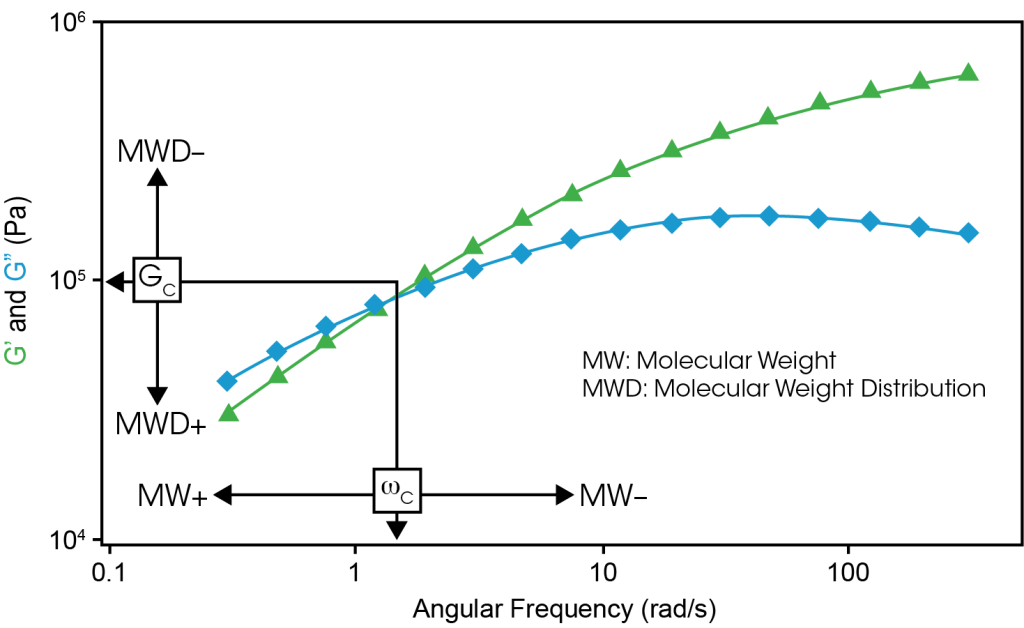

How is viscoelasticity related to Molecular Weight/ Molecular Weight distribution?

Oscillatory tests on rotational rheometers provide valuable insights into a polymer’s viscoelastic properties by probing the polymer’s structure through small deformations over a range of time scales. The results provide the polymer’s Storage Modulus (G’), Loss Modulus (G”) and complex viscosity (η*) as a function of the oscillation frequency and can be used to better understand the dynamics of polymer relaxation. These parameters are strongly influenced by resin’s molecular weight, molecular weight distribution, and long chain branching structure. Compared to melt flow indexers or capillary rheology, the viscoelastic profile from rotational rheology testing is particularly sensitive to the presence of high molecular weight contamination that can cause processing issues.

Answer the following questions with viscosity and viscoelastic measurements from your rotational rheometer:

- Feedstock evaluation: How is the viscoelastic profile affected by batch-to-batch changes in the resin’s Molecular Weight/ Molecular Weight Distribution?

- Processability: Does the resin have the right viscosity at all shear rates relevant to the manufacturing process?

- End-of-life: End-of-life recycling: How do contamination and MW variation in the recycled resin impact processing?