Keywords: Q5000 SA, Moisture Sorption, Latex Paints, Temperature, Humidity

TA333

Abstract

This application brief describes the utility of the TA Instruments® Q5000 SA for monitoring the drying of latex paints.

Introduction

Moisture Sorption analysis is an established technique for determining the effect on materials of exposure to controlled conditions of temperature and relative humidity (RH). Isotherm and Isohum experiments are the most common analyses. In isotherm experiments, a weighed sample is “dried” externally, or preferably in the instrument, and exposed to a series of humidity step changes at constant temperature. The sample is staged at each humidity level until no further weight change is detected or a set time has elapsed. A data point is recorded, the humidity is changed in 5 or 10% RH steps and the process repeated in an upward and/or downward procedure. Isohum experiments involve a series of temperature step changes at constant humidity and result in similar plots. They are used to determine how sample exposure to a given humidity results in a physiochemical change, such as a change in the sample’s hydration state. Historically, these techniques have been prevalent in the pharmaceutical, food, and personal care industries and a significant amount of relevant information has been reported.

The Q5000 SA represents the state-of-the-art in moisture sorption analyzers. Its design integrates the latest high sensitivity, temperature controlled thermobalance with an innovative humidity generation system, advanced autosampler with sealed-pan punching, and excellent software. This creative and flexible design makes the Q5000 SA ideal for non-traditional moisture sorption experiments, and extends the application of this field to a wide range of samples.

Experimental and Discussion

Latex paint is a widely used product with many applications, and as such is applied under considerably varying conditions. In most interior applications the temperature and humidity are tightly controlled, and thus the rate of drying of the paint emulsion can be accurately predicted. However, the rate of drying is highly dependent on both temperature and relative humidity. Minor variations in either (such as those experienced in typical seasonal climate change) can contribute to drastic changes in drying kinetics, which may influence product effectiveness.

In this study, a common household latex paint was analyzed using the Q5000 SA moisture sorption analyzer. The paint was initially stirred per the manufacturer’s instructions. Samples were then drawn, placed into special sealed aluminum crucibles and were then loaded onto the robotic autosampler of the Q5000 SA to await analysis. Just prior to insertion into the humidity chamber, the Q5000 SA can automatically punch open the sealed pan (as shown in Figure 2). This ensures the sample does not “pre-dry” before gravimetric analysis is performed.

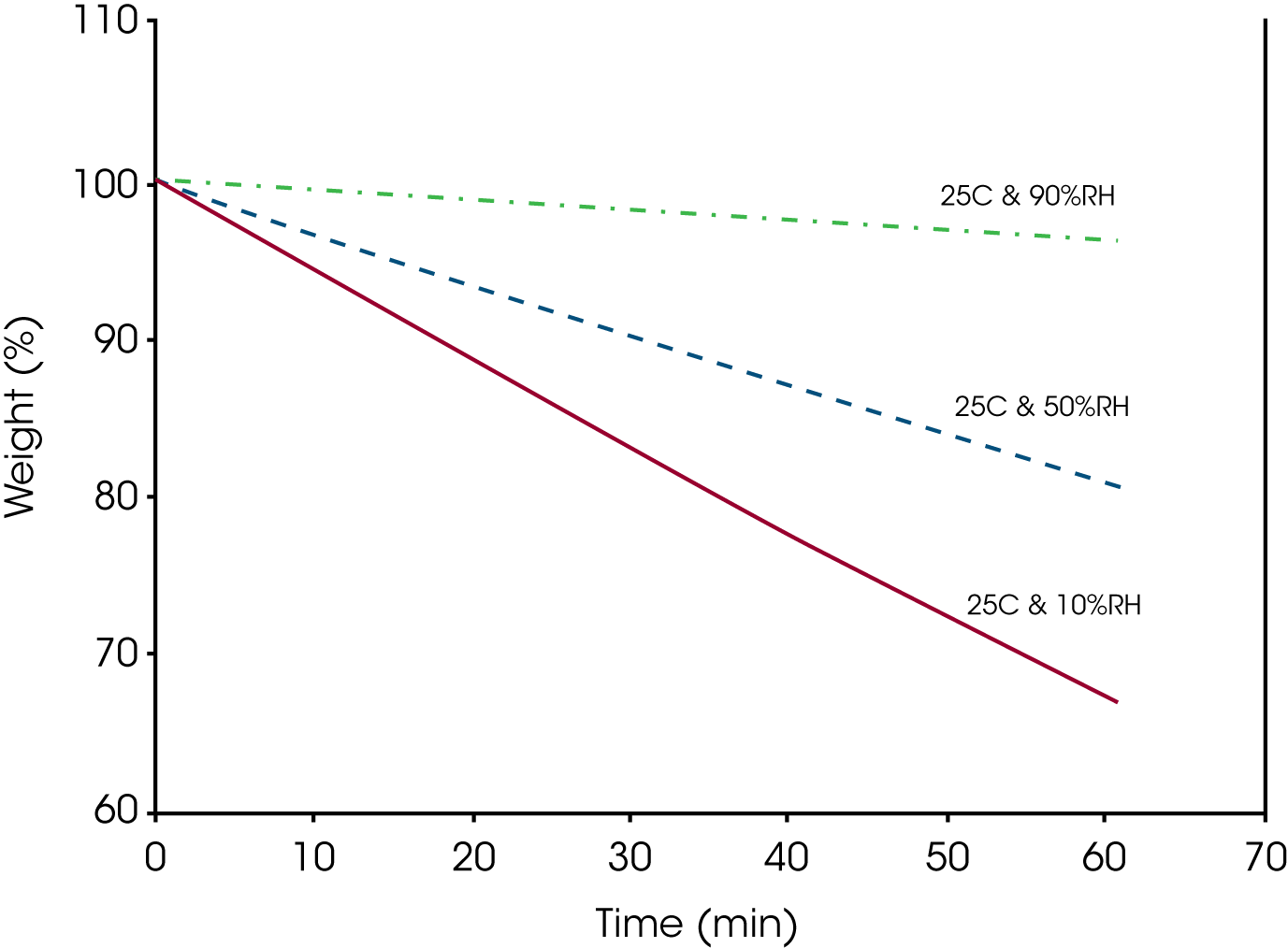

Figure 3 contains the data from the drying of the latex at 25°C, and 10%, 50% or 90% relative humidity. As the latex paint dries, the sample weight decreases: the rate of weight loss is proportional to the rate of drying. From the data in Figure 3, it is clear that the relative humidity dramatically influences the rate of drying. After 60 minutes, the sample at 10% RH has lost nearly 33% of it is initial mass, whereas the sample at 90% RH has lost only about 4%. Obviously, the sample at 90% RH would still be considered “Wet Paint” after one hour.

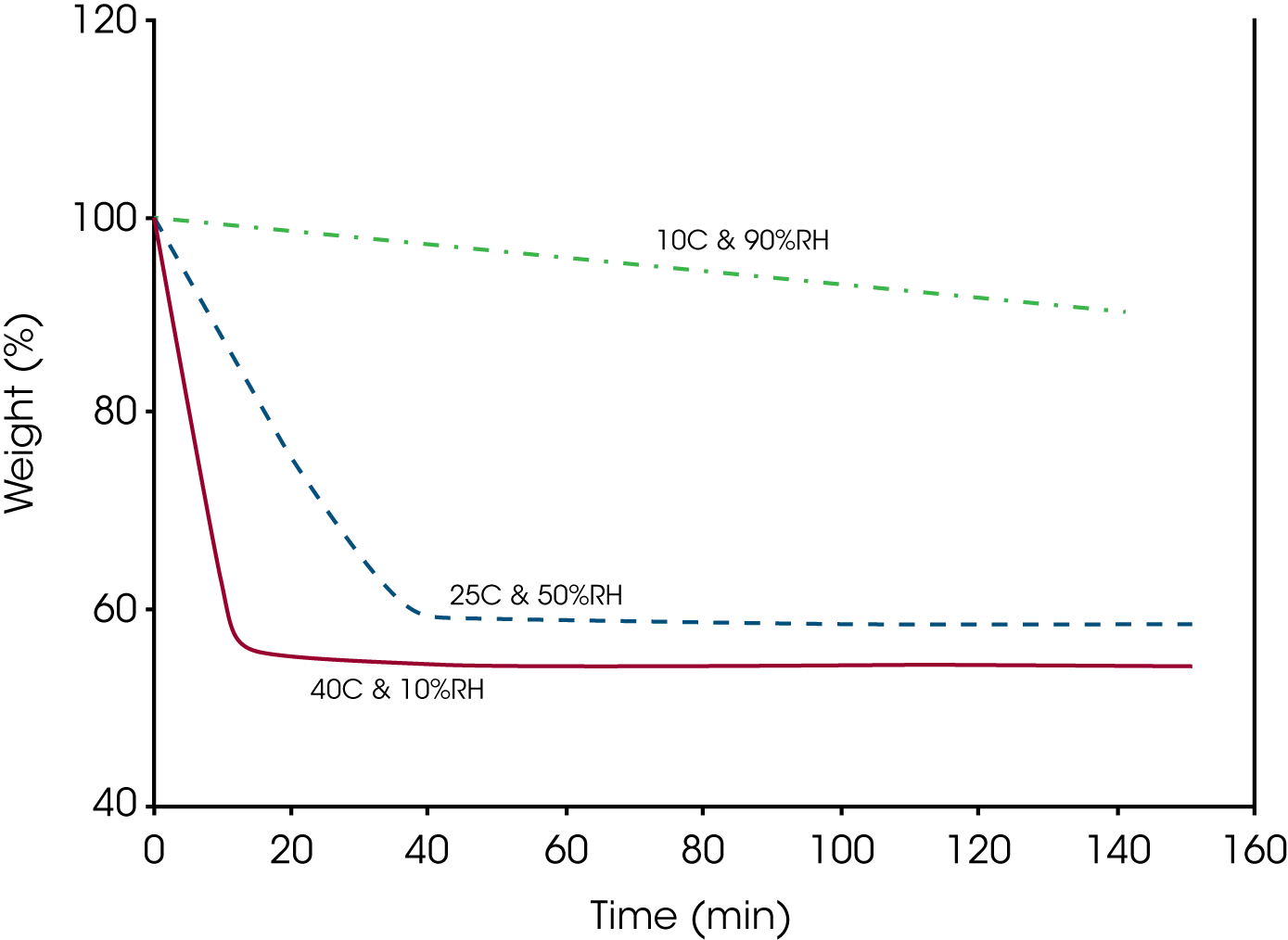

The data in Figure 4 represent varying both temperature and humidity. The ranges were chosen to represent realistic extremes in climatic conditions. The data suggest that while the rate of drying is affected by RH, the temperature dependence is also significant. The sample held at 40°C (104 °F) and 10% RH dries fully in about 20 minutes, whereas the sample analyzed at 10°C (50°F) and 90% RH is far from dry after nearly 2.5 hours.

Based on the data from the Q5000 SA, the rate of drying of the latex paint samples can be precisely measured as a function of both temperature and relative humidity. This is a valuable analysis when designing paint formulations, preparing product recommendations, and predicting end-use performance. The Q5000 SA is shown to be an integral tool for these analyses.

Acknowledgement

Click here to download the printable version of this application note.