Keywords: Discovery TMA 450 RH, controlled humidity, polyamide, nylon, glass transition, plasticization

TA445

Introduction

The Discovery TMA 450 RH

A traditional Thermomechanical Analyzer (TMA) measures the dimensional change of a sample as a function of time, temperature, or atmosphere. By performing heating, cooling, or isothermal experiments key material properties such as the glass transition temperature (Tg) or the coefficient of thermal expansion (CTE) can be studied. This is especially important when determining the compatibility of materials which are meant to function together in a final part. For example, a mismatch in CTE between a coating and substrate can lead to delamination and part failure.

With the use of a TA Instruments Discovery Thermomechanical Analyzer equipped with Relative Humidity Accessory (TMA 450 RH) a material’s change in dimension can now be analyzed as a function of humidity. The Discovery TMA 450 RH combines a non-contact, friction-free motor, and high-resolution dimensional change measurement transducer with an integrated humidity-controlled sample chamber to allow for the recording of precise dimensional measurements with coordinated control of both temperature and humidity.

The control of humidity and temperature afforded by the Discovery TMA 450 RH allows for the characterization of many, potentially crucial, material properties relevant in new product development as well as fundamental materials research. Some potential studies with this instrument include:

- Measure swelling or shrinking of a material due to adsorption and desorption of moisture.

- Characterize the Coefficient of Hygroscopic Expansion (CHE).

- Investigate changes in Tg as a function of humidity.

- Detect morphology changes, such as crystallization or cross-linking induced by changing humidity conditions.

- Determine multi-layer component compatibility in humid or dry environments.

- Record drying force under isostrain conditions.

Synthetic Polyamides

Synthetic polyamides, such as Nylon, exhibit outstanding material properties and can be processed and blended with a wide variety of additives which can make them well suited to many different industries. Depending on the intended application, polyamides can be formulated to target different physical and thermal properties. Nylons are well known to be used extensively in textiles, but they can also be found as rigid molded parts in the electronics and automotive industries, as films in food packaging, or as surgical sutures due to being inert in a biological environment.

It is well understood that nylon is hygroscopic. Nylon can absorb water out of the air, increasing the weight and dimensions of a part and fundamentally changing its material properties. Water molecules will absorb into the material and act as a plasticizer, increasing molecular mobility and lowering the glass transition temperature. The rate and amount of water absorbed can depend on factors such as: relative humidity, temperature, exposure time, and sample thickness. Given the wide variety of potential environmental conditions which nylon may be exposed to (depending on a certain application requirement) it is crucial to understand how that material will react under those conditions.

This Applications Note showcases the capability of the Discovery TMA 450 RH to monitor the change in Tg of a nylon sample as a function of relative humidity.

Experimental

For this work a sample of nylon film was cut and loaded into the Film/Fiber Probe of the Discovery TMA 450 RH. The initial length of the film was 16 mm. The design of the sample holder and probe allows for the humid atmosphere to flow freely around the sample. The probe applied a preload force of 0.05 N to ensure the film was kept in tension and would not buckle during the experiment. All film samples were conditioned at a given relative humidity (%RH) at 25 °C for 8 hours to allow for the moisture uptake into the sample to reach equilibrium.

A dynamic temperature ramp experiment was performed in the Discovery TMA 450 RH on the conditioned Nylon samples. In a dynamic TMA temperature ramp a sample is subjected to an oscillating force while the temperature is ramped linearly. Humidity is held constant, and the mechanical properties of the sample are measured. While the sinusoidal force is applied the instrument is able to monitor the material’s response to the stress. If a material is perfectly elastic the response will be exactly in phase with the applied force, and if a material is perfectly viscous it will be exactly 90 degrees out of phase with the sinusoidal wave. Most polymers are viscoelastic and their response to applied stress lies between these two extremes. The delay in response to the applied deformation can be quantified as the phase angle (δ). The tangent of the phase angle can be analyzed to determine the mechanical damping behavior of a material as a function of temperature. The Tg of a viscoelastic material corresponds to the maximum of this damping behavior and therefore can be identified as the temperature at which the maximum Tanδ is observed.

After conditioning at 25 °C at the selected humidity level, the nylon samples were equilibrated at 5 °C and the dynamic TMA experiment was begun. An oscillatory force of 0.10 N was applied at a frequency of 0.50 Hz. The chamber was thermally ramped at 1.0 °C/min from 5 °C to 100 °C. The temperature ramp was also performed while keeping the set humidity constant, which is a parameter that can be selected while using the Discovery TMA 450 RH.

Results

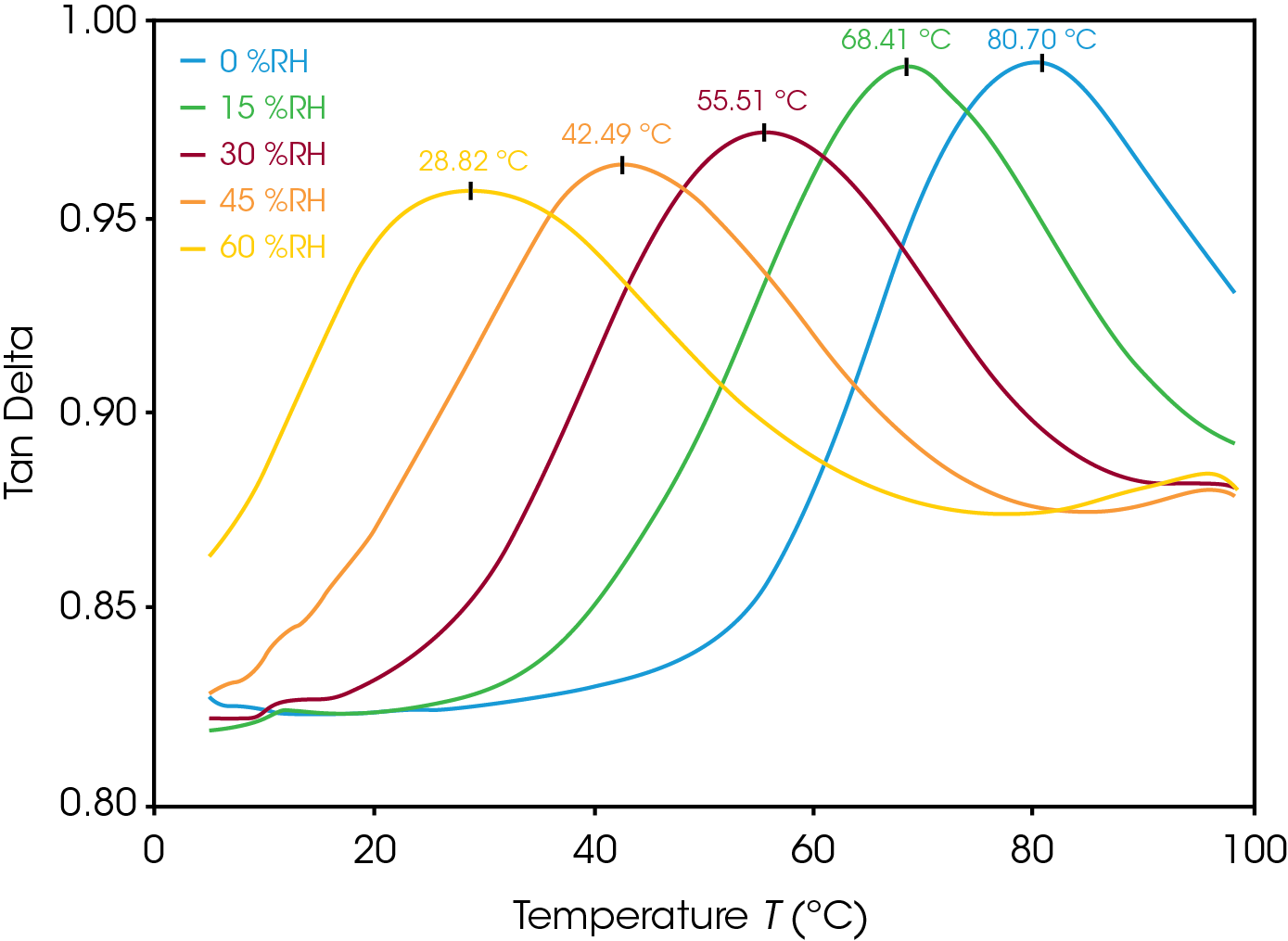

Nylon film samples were conditioned for 8 hours at 25 °C at relative humidity levels of 0 %RH, 15 %RH, 30 %RH, 45 %RH, and 60 %RH. Figure 3 shows an overlay of the Tanδ of these samples as a function of temperature. The sample conditioned at 0 %RH was exposed to a constant purge of dried nitrogen gas. The effect of plasticization (as identified by a reduction in the Tg) from the exposure to humid atmosphere is readily apparent. Note that between the humidity levels of 30 %RH and 45 %RH the nylon samples show a 13 °C reduction in glass transition temperature. These are common and realistic humidity levels which a nylon part could be exposed to during use, depending on location, climate, or time of year. This exemplifies the necessity to understand the behavior of materials as a function of humidity, especially strongly hygroscopic materials such as polyamides.

Conclusion

The Discovery TMA 450 RH allows for precise control of relative humidity within the sample chamber throughout a thermomechanical experiment. Various critical material properties can be studied as a function of humidity including the glass transition temperature. Detecting and tracking changes to the glass transition is critical to the research and development of new materials, as well as for understanding the compatibility of materials. Glass transition is known to be affected by plasticization which commonly occurs due to water uptake. In this Applications Note it was demonstrated that the effect of water uptake and plasticization on the Tg of a hygroscopic material, such as nylon, can be directly studied while controlling humidity and temperature with the use of the Discovery TMA 450 RH.

Acknowledgement

This note was written by Andrew Janisse, Ph.D., Applications Scientist at TA Instruments.

Click here to download the printable version of this application note.