Keywords: hydrogels, wound dressing, viscoelasticity, DMA, dynamic mechanical analysis

EF034

Abstract

Hydrogels are used for a range of applications. In this study, we characterized two different types of topical wound dressing hydrogels, one specialized for radiation dermatitis, and another for low exudating wounds using dynamic mechanical analysis (DMA) techniques. This mechanical characterization was performed on a TA Instruments ElectroForce DMA 3200 system which provided a quantification of the linear viscoelastic region (LVR) for these dressings using a strain sweep, and their dynamic response at different frequencies using a frequency sweep at different strain levels both within and outside the LVR. The DMA 3200 was able to successfully measure the viscoelastic properties of these soft dressings within and beyond the LVR and was additionally able to quantify these properties at a range of different frequencies.

Introduction

Hydrogels have a structure comprised of aggregates of polymer chains that act to constrain a working fluid, typically water or saline. The relative concentration of polymer and the length of the polymer chain are understood to be important factors in the mechanical properties of hydrogels [1]. Thus, the mechanical properties of hydrogels are extensively tunable via modification of different compounding and fabrication parameters, which is an advantage that has seen the widespread adoption of these materials in a variety of different fields, such as in the development of wound dressings and contact lenses. Hydrogels also exhibit a high degree of biocompatibility [2], which makes them well suited to the fabrication of prosthetic tissue and in vivo drug delivery devices.

The dynamic shear mechanical properties as well as the uniaxial stiffness and failure properties (as measured by quasi-static compression or tension) of these hydrogels as a function of these parameters have been extensively studied [3]. However, characterization of their viscoelastic properties under axial loading has been a less popular avenue of exploration. Such characterization has the potential to provide insight on the structure-properties relationship between various fabrication techniques and end-use hydrogel products. Specifically, axial DMA can provide measurements of storage modulus (a measure of the stiffness of the material), loss modulus (a measure of the material’s tendency to dissipate strain energy, and tan-delta (a measure of the damping capabilities of the material). In this study, these properties and their dependence on material strain and testing frequency were identified for two wound dressing hydrogels.

Experimental

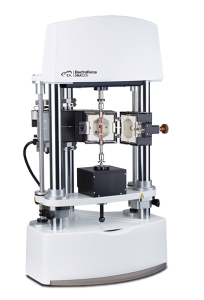

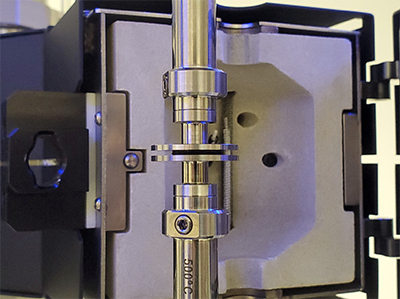

Two commercial wound dressing hydrogels, labelled as intended for use for radiation dermatitis and low exudating wounds respectively, were characterized for this study. Samples arrived as 4” x 4” sheets of a supporting mesh sandwiched between 10.5% poly (ethylene oxide) hydrogel material. These constructs were packaged between two plastic sheets to prevent drying of the hydrogel material during storage and transit. Test samples were created by removing the protective plastic sheathing and then using a circular punch to cut out cylindrical samples of approximately 14 mm diameter and 1.5 mm thickness. Mechanical characterization was performed using a TA Instruments ElectroForce DMA 3200 equipped with a 22N force sensor. The instrument uses a linear electromagnetic motor to apply oscillating axial stress to the sample while measuring both the sample force and displacement. The instrument performs DMA calculations based on the force and displacement measurements to derive the viscoelastic material parameters.

Testing was performed at room temperature using a set of 25 mm compression platens. To determine the LVR of these samples, a strain sweep between 0.01% strain and 10% strain was performed at 1 Hz. The LVR was determined by measuring the storage modulus at a reference strain and then determining the strain at which this storage modulus had changed by more than 5%. Following this analysis, frequency sweeps from 0.1 Hz to 100 Hz were performed at strain levels of 0.25% and 1% strain.

Results and Discussions

Although both hydrogel constructs analyzed for this study were indicated to have the same relative composition of water and hydrogel material, dynamic mechanical characterization may illuminate any mechanical differences present due to modifications (chemical or otherwise) made to each gel material to specialize them for application towards radiation and low-exudating wounds respectively. Typically, DMA measures three intrinsic material properties during testing – storage modulus, loss modulus, and tan-delta. In this specific application, the storage modulus of these dressings is indicative of the firmness of the dressing, and the loss modulus and tan-delta are indicative of the damping or viscous character of the dressing.

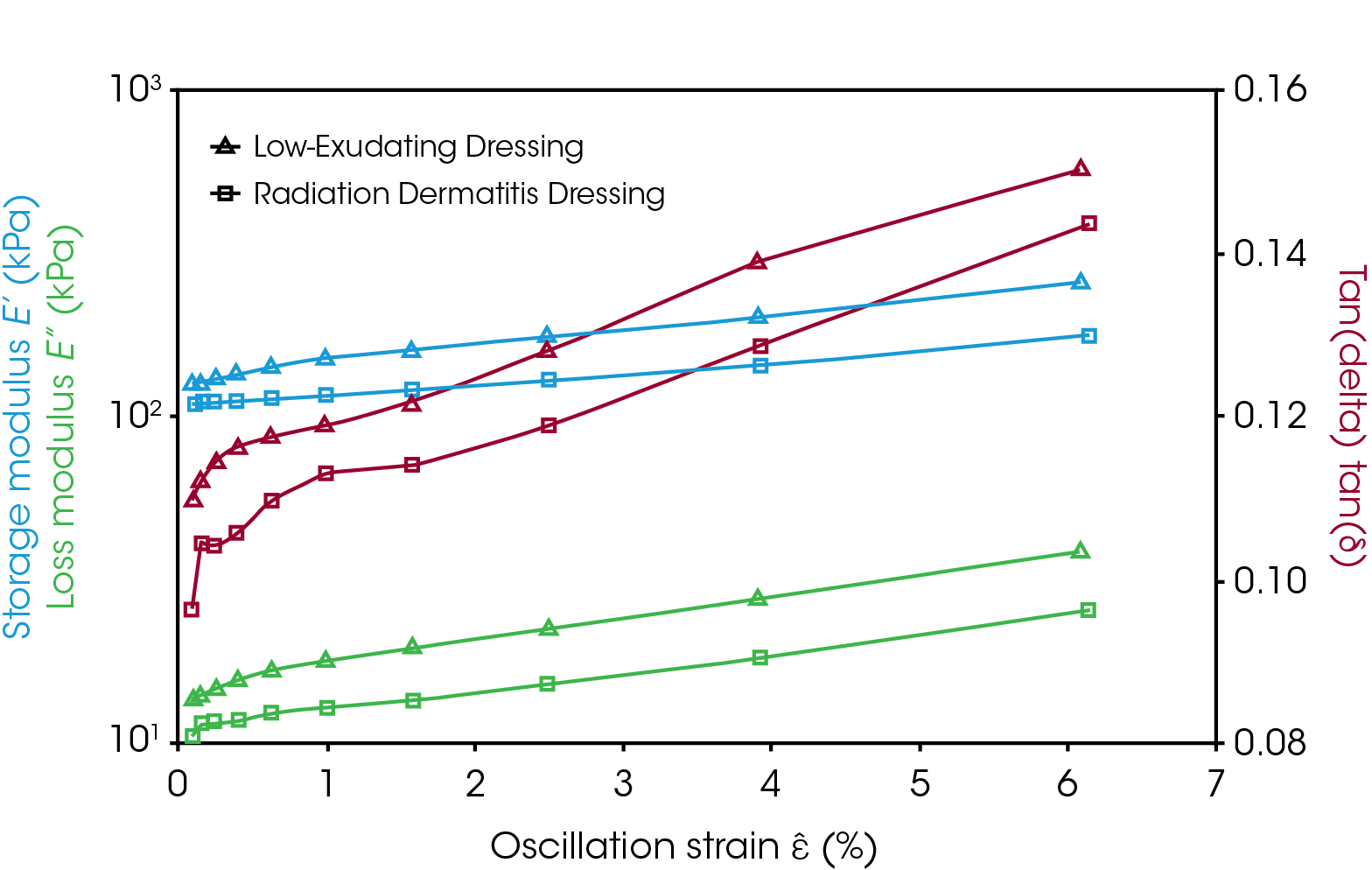

When characterizing materials with relatively understudied dynamic mechanical behavior, it is typically appropriate to begin the characterization process with an analysis of the strain-dependent mechanics of the material via a strain sweep. Comparing the strain sweep behavior between the two different types of dressings (Fig. 3), we observe that both types of dressings exhibit similar viscoelastic material behavior across the same strain levels, with the low-exudating specialized dressing indicating slightly higher storage and loss modulus measurements, and a higher tan-delta measurement as well.

The 22N load sensor on the DMA 3200 instrument was able to detect a well-defined sinusoidal loading waveform of 0.04N pk-pk force at 0.1% strain for both types of dressings. This provided a reliable reference for low-amplitude storage modulus. From that reference, the strain level corresponding to a 5% (or lower) change in storage modulus for each of these gels was found to be 0.25% for the low-exudating dressing, and 0.63% for the radiation dressing. While testing on a larger number of samples is prudent to establish these values, this result indicates that a 0.25% strain level can be used to compare their response in the linear ranges.

Table 1. Change in storage modulus at low strain levels for low-exudating dressing

| Strain Level | Storage Modulus (kPa) | Increase |

|---|---|---|

| 0.1% | 126.10 | Reference |

| 0.25% | 130.33 | 3.4% |

| 1% | 151.81 | 20.4% |

Table 2. Change in storage modulus at low strain levels for radiation dressing

| Strain Level | Storage Modulus (kPa) | Increase |

|---|---|---|

| 0.1% | 109.66 | Reference |

| 0.25% | 111.10 | 1.3% |

| 1% | 115.70 | 5.5% |

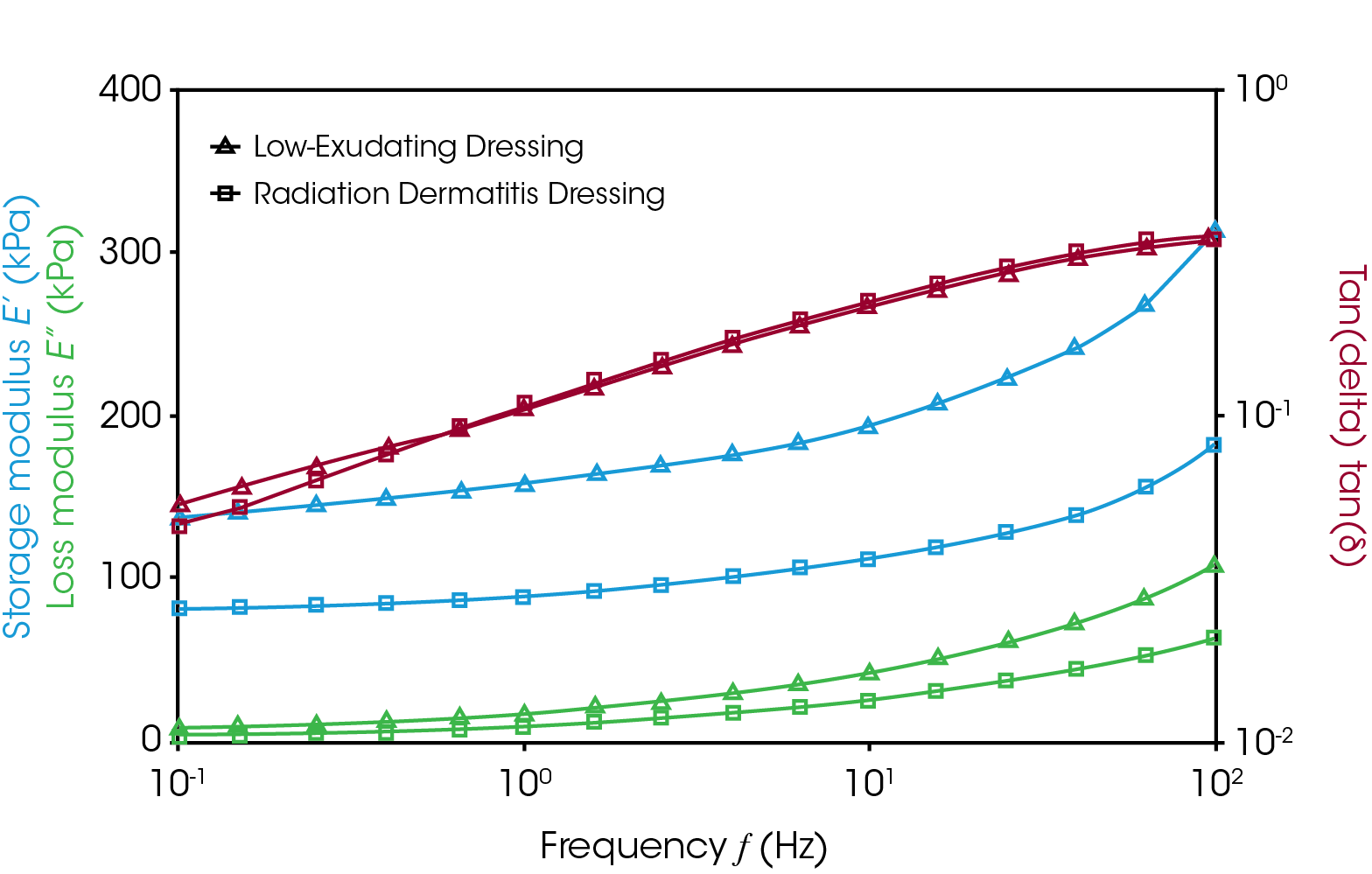

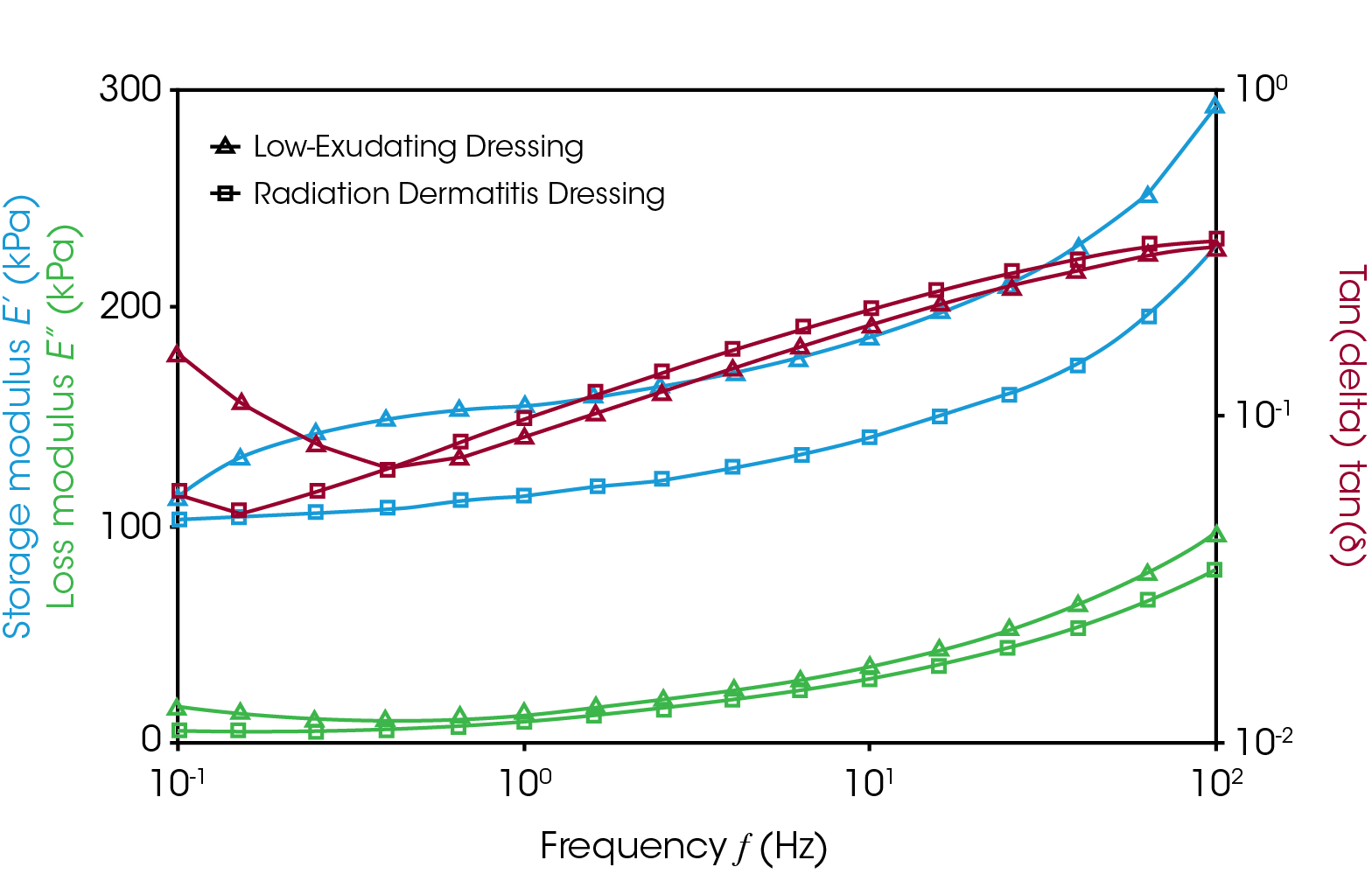

Comparison of viscoelastic properties at different frequencies for both dressings yielded similar patterns of mechanical behavior as those obtained during a strain sweep. From the frequency sweeps performed at 0.25% strain (Fig. 4), we observed that the storage moduli for the low-exudating dressing were approximately 50% higher than that of the radiation dressing at all tested frequencies. However, the tan delta measurements for both types of dressings were similar, indicating that both dressings showed a similar degree of damping across all tested frequencies.

From the frequency sweeps performed at 1% strain (Fig. 5), we observed that the low-exudating dressing shows a higher damping response and a decreased stiffness at lower frequencies as compared to the radiation dressing. As our measurements of LVR for both types of dressings indicated that the low-exudating dressing exhibited a lower LVR than the radiation dressing, this result may have been caused by an increased degree of relaxation exhibited by the low-exudating dressing as compared to the radiation dressing under higher strain conditions. However, further studies are warranted to establish this result, as significant package-to-package variation in this property was observed during testing.

Conclusions

The viscoelastic properties of wound dressing hydrogels can be characterized using a DMA 3200 instrument with a 22N load sensor. While further studies are warranted to establish mechanical differences between the viscoelastic properties of these wound dressing hydrogels, this report illustrates how dynamic mechanical analysis can be applied to soft polymeric samples to glean insights into material behavior.

References

- Zustiak, Silviya P., and Jennie B. Leach. “Hydrolytically Degradable Poly (ethylene glycol) Hydrogel Scaffolds with Tunable Degradation and Mechanical Properties.” Biomacromolecules 11.5 (2010): 1348-1357.

- Harris, J. Milton, ed.” Poly (ethylene glycol) Chemistry: Biotechnical and Biomedical Applications.” Springer Science & Business Media (1992).

- Kloxin, April M., et al. “Mechanical Properties of Cellularly Responsive Hydrogels and their Experimental Determination.” Advanced Materials 22.31 (2010): 3484-3494.

Acknowledgement

Click here to download the printable version of this application note.