Don’t Let Bad Rheology Data Burn You

Behbood Abedi

July 14, 2025

This part of our Rheology is Fun! Series. In this series, we take a cursory exploration of some of the fun, and perhaps unexpected, activities around us that involve rheology.

Summer is all about sunshine, pool days, and of course — sunscreen. But while most people are focused on SPF and water resistance, we’re here to talk about something just as important (and way more fun if you’re a science nerd): rheology.

That’s right — how your sunscreen flows, spreads, and feels isn’t just a matter of preference. It’s science.

And if your R&D team is tweaking a sunscreen formulation, whether it’s to meet new regulations, respond to consumer trends, or deal with supply chain surprises — rheology can make or break your product.

In this blog, we put a few sunscreen formulations to the test.

We compared three SPF 50 sunscreens from the same brand:

- Sheer Zinc Mineral Sunscreen – with Zinc Oxide 21.6% as the active ingredient.

- Sheer Zinc Kids Mineral Sunscreen – also Zinc Oxide 21.6%, but free of fragrance, parabens, and dyes.

- Oil-Free Chemical Sunscreen – a chemical formulation mostly with Avobenzone 3%, Homosalate 10%, Octisalate 5%, and Octocrylene 10%.

From rubbing to dabbing, and even what happens when you leave your sunscreen in a hot car — we’ve got the data, the curves, and the insights. Because when it comes to formulation changes, bad rheology data can leave you burned — figuratively and literally.

Let’s dive in.

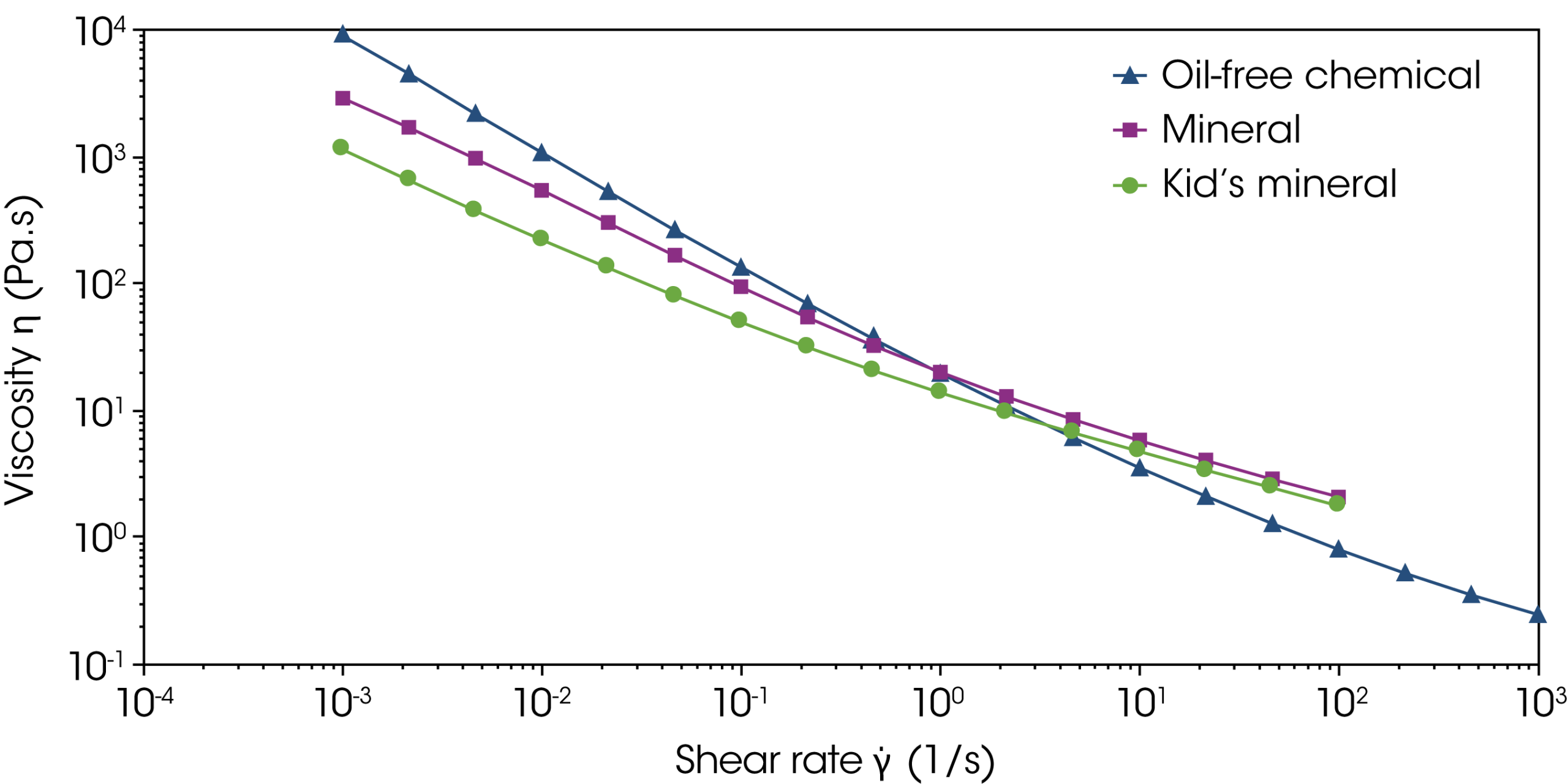

We kicked things off by comparing the flow behavior of three sunscreens. The results are shown in Figure 1.

The oil-free sunscreen formulation showed more pronounced shear thinning — meaning it flows more easily the more you rub it. Looking at these results, we can see that the oil-free formula has the highest yield stress, shown by having the highest viscosity at the lowest shear rate. Think of yield stress as the amount of force (or stress) you need to apply to a material before it finally says, “Okay, fine, I’ll move!” However, due to the shear thinning behavior, it actually feels less viscous on the skin as you rub it in when compared to the other formulations. Both mineral sunscreens will feel similarly viscous during application.

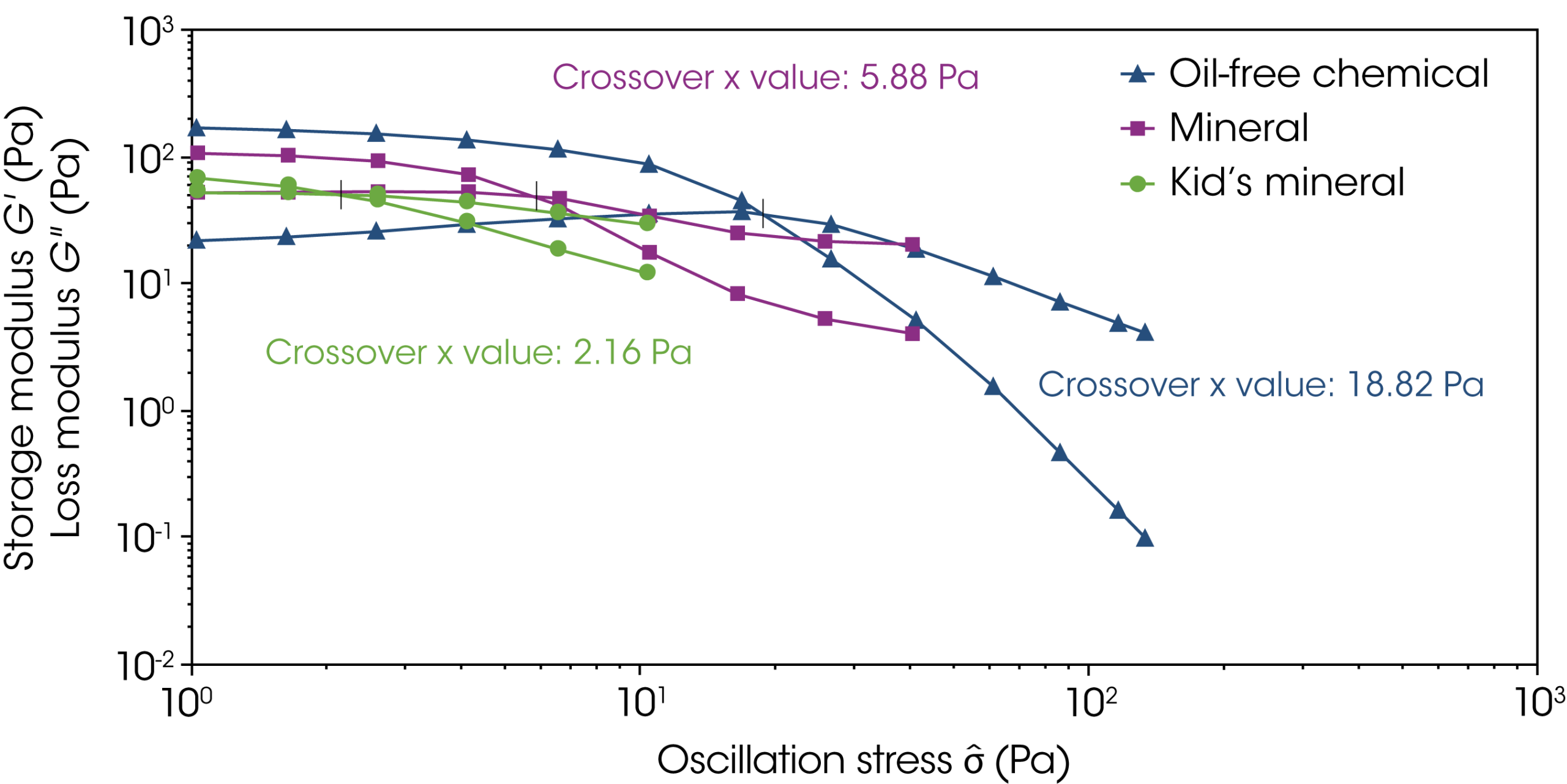

Since rubbing sunscreen is essentially a solid-to-fluid transition, yield stress becomes a key player — more specifically, the static yield stress. Static yield stress is the stress needed to start the flow from rest and is obtained in Figure 2. Dynamic Yield Stress is the stress needed to keep the material flowing once it’s already moving (obtained in figure 1). To get a better handle on this, we also ran an oscillatory stress amplitude sweep starting from relatively low stress (see figure 2).

The results aligned well with our flow sweep data: overall, the oil-free formulation exhibited higher static and dynamic yield stresses, while the two mineral-based ones were pretty much neck and neck.

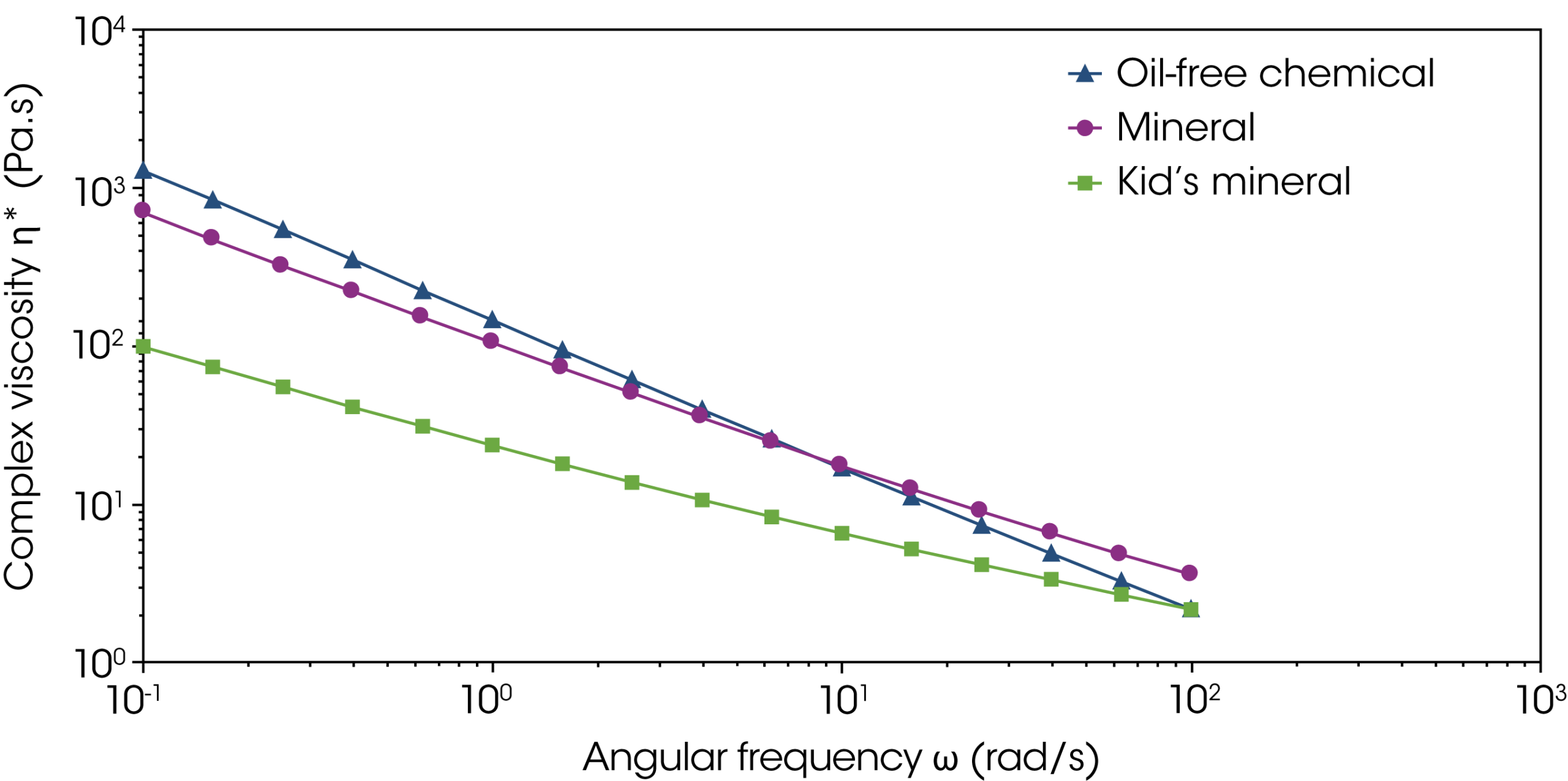

But what if you’re a dabber, not a rubber when it comes to applying sunscreen? Oscillatory testing is a great proxy for dabbing, so in Figure 3 we looked at complex viscosity, which is obtained in oscillatory frequency sweeps.

Again, the oil-free formulation stood out with stronger shear thinning. At higher frequencies, the complex viscosities of the mineral sunscreens converged. But interestingly in this dabbing scenario, the kids’ mineral sunscreen feels less viscous than the adult mineral one.

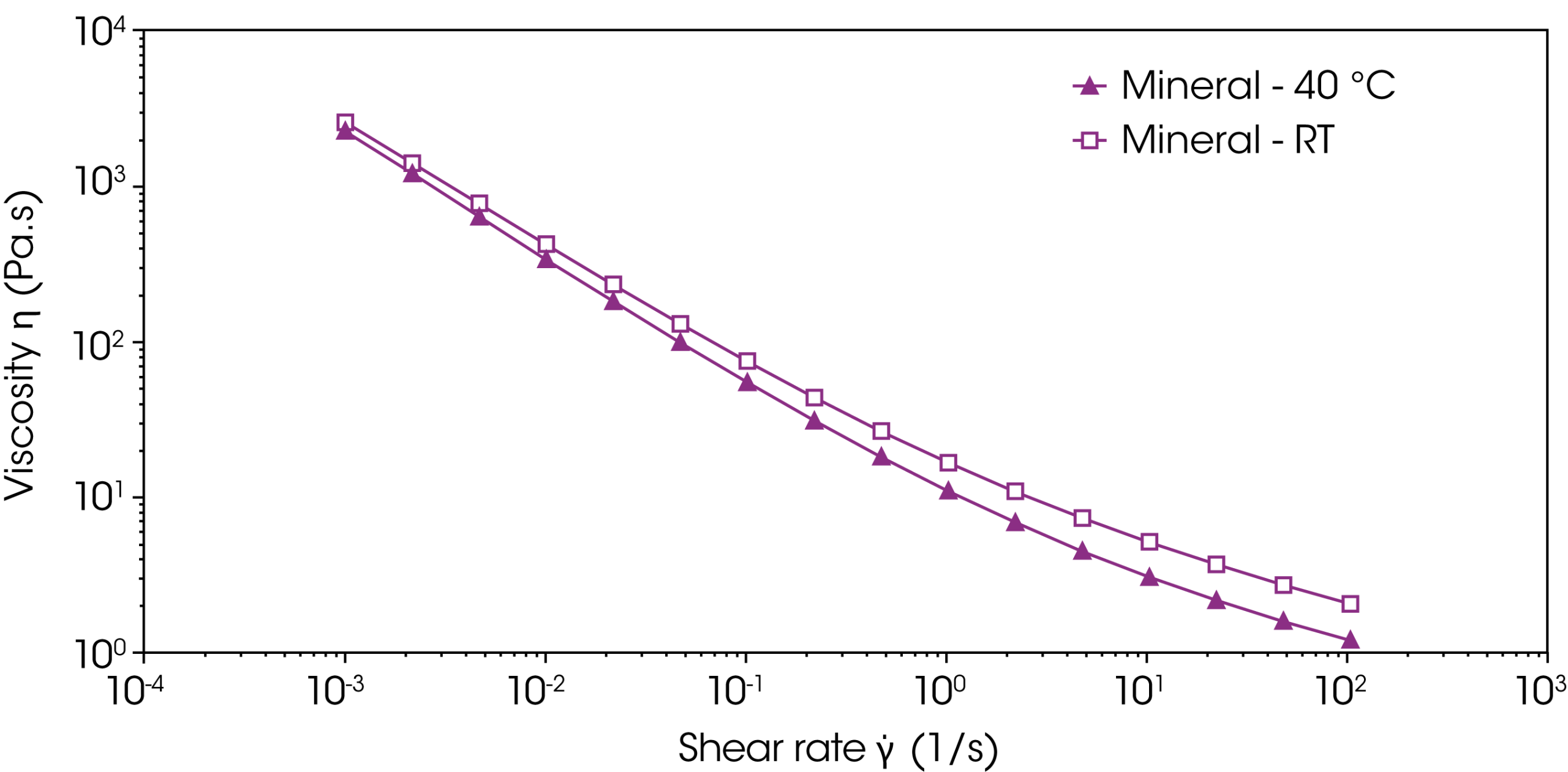

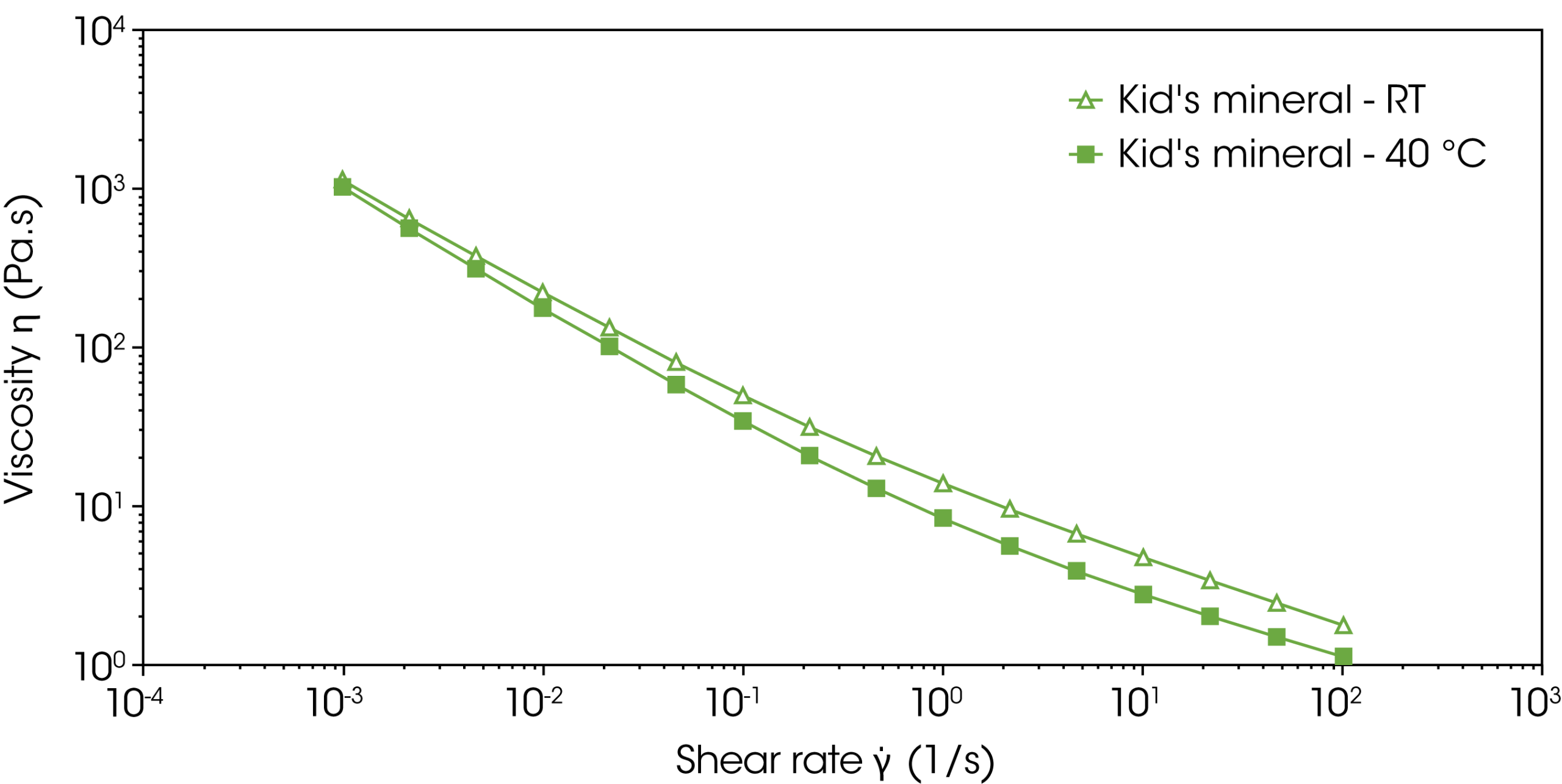

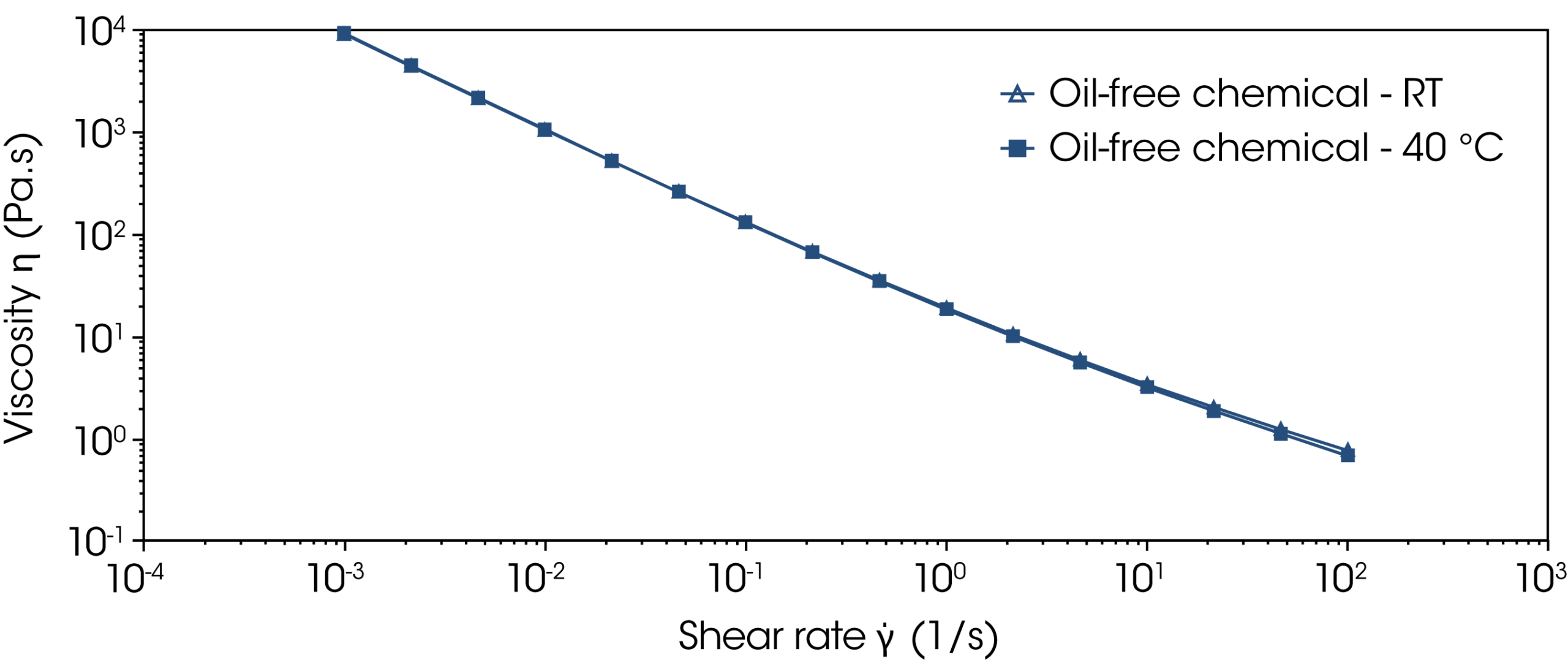

Next, we simulated a classic summer mistake: leaving your sunscreen in a hot car. When warmed up, the mineral formulations’ viscosity dropped approximately by about 40% (Figures 4 and 5). While this might sound like a plus because the sunscreen is easier to rub in, this viscosity drop can actually lead to messy situations, with the sunscreen either gushing out of the tube or dripping off your skin before you get a chance to spread it properly.

The oil-free version? Barely changed, as shown in Figure 6. That’s a win for stability under summer heat.

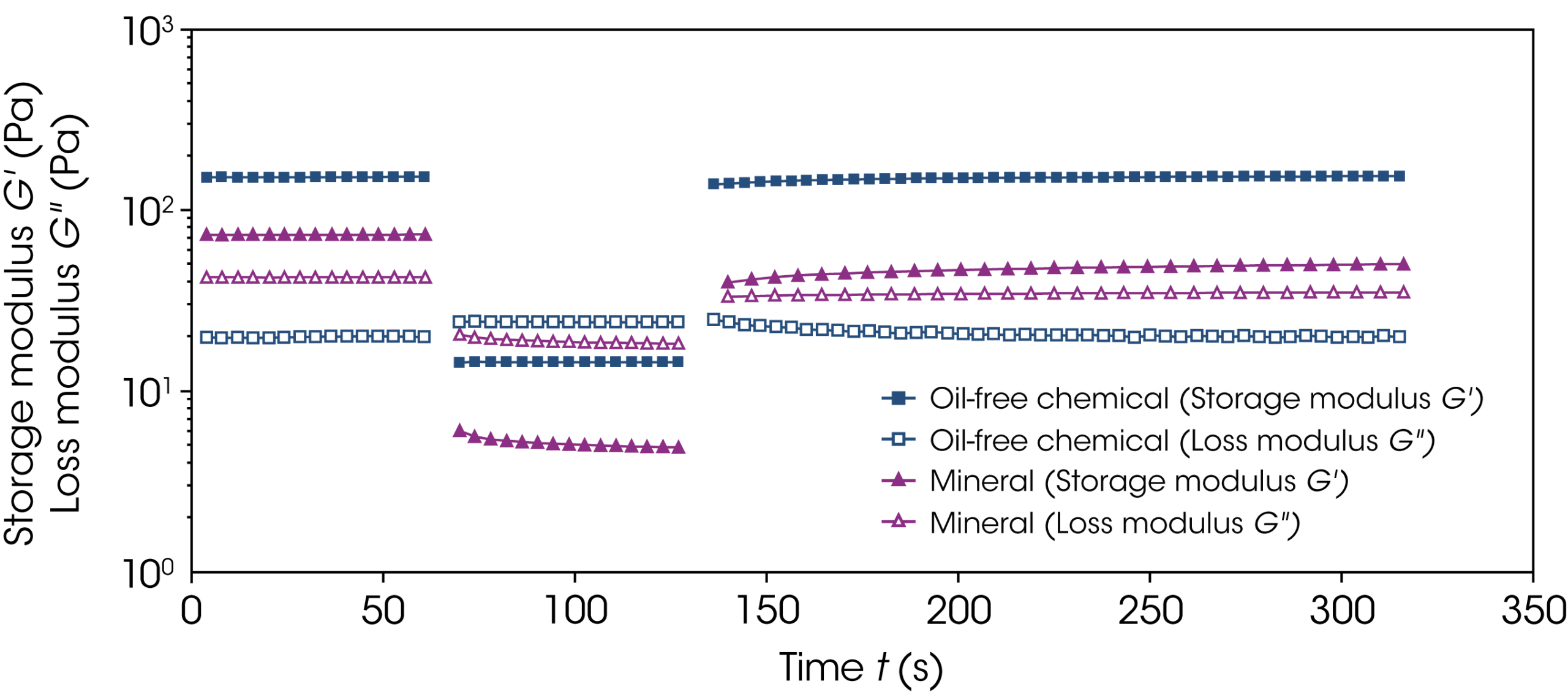

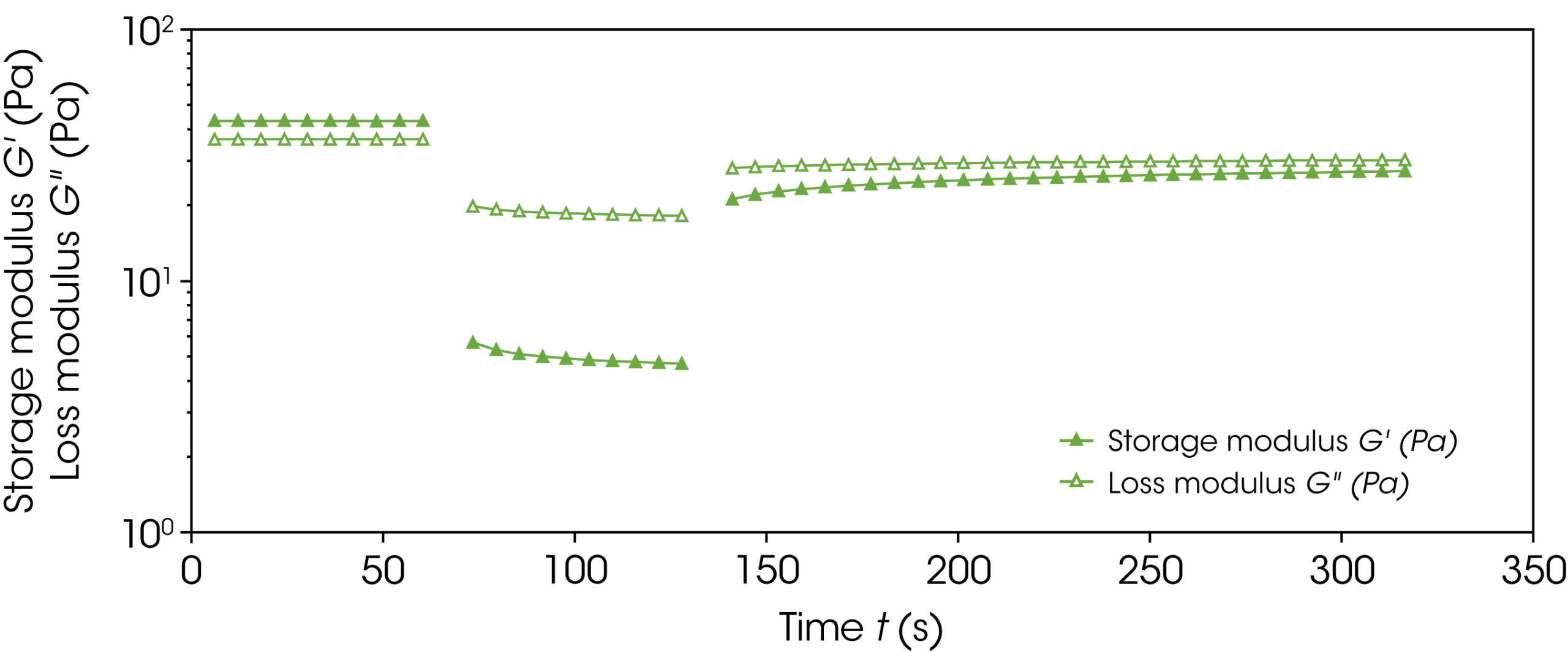

Finally, we looked at how these sunscreens rebuild on the skin after rubbing (Figures 7 and 8).

Both the mineral and oil-free formulations showed minimal thixotropy, meaning they recovered their microstructure quickly. The oil-free sunscreen even had a higher storage modulus, suggesting a more elastic, stable film.

But the kids’ formulation? Not quite the same. Across three repeated tests, its microstructure never fully recovered after rubbing. The loss modulus consistently exceeded the storage modulus, indicating a more fluid-like, less elastic behavior. This may be intentional to create a gentler, smoother film for sensitive skin.

What did we learn from all this sunscreen science? Whether you’re rubbing, dabbing, or accidentally baking your sunscreen in a hot car, rheology tells the story behind the squeeze. From yield stress to complex viscosity, from recovery behavior to thermal stability, each formulation has its own flow personality — and those differences matter.

The takeaway? Every formulation tweak changes the rheology — and that can change how your product feels, spreads, and protects. So, if you’re in R&D, don’t skip the rheology. Because in sunscreen science, bad data can leave you burned.

Other Resources

- Blog – Advance Formulation Performance with Rheology Studies

- Blog – Rheology Theory and Applications

- Blog – Viscometer vs Rheometer: Discover Why a Rheometer Offers More Than Just Viscosity Measurement

- Application Note – Predicting Performance of Pharmaceutical Lotions Through Rheological Characterization

- Product – Discovery Core Rheometer