Coffee Powder Rheology

The Rheological Journey of Coffee Powders from Bean to Brew

Behbood Abedi

June 2, 2025

This part of our Rheology is Fun! Series. In this series, we take a cursory exploration of some of the fun, and perhaps unexpected, activities around us that involve rheology.

Coffee lovers know that the grind size and roast degree of coffee beans can significantly impact the flavor and texture of their favorite beverage. But did you know that these factors also affect the rheological properties of coffee powders? Rheology, the study of flow and deformation, provides valuable insights into how coffee powders behave under different conditions.

In this blog, we explore the fascinating world of coffee powder rheology, examining how grind size and roast degree influence the behavior of coffee powders. By comparing coarse and fine grounds of medium roast coffee, as well as coarse grounds of medium and dark roast coffee, we uncover the unique rheological properties that contribute to the perfect brew.

We compare the compressibility, wall friction, confined flow energy, cohesion, and flow function of coffee powders to understand their behavior in various processes such as hopper, dosing, tamping, and puck formation.

Whether you’re a coffee enthusiast or a science geek, this blog offers a fun and informative look at the intersection of coffee and rheology. Ready to brew some knowledge? Let’s get started!

Grind Games: Comparing Coarse and Fine Grounds of Medium Roast Coffee

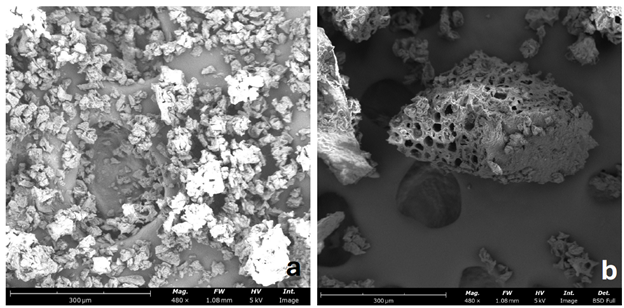

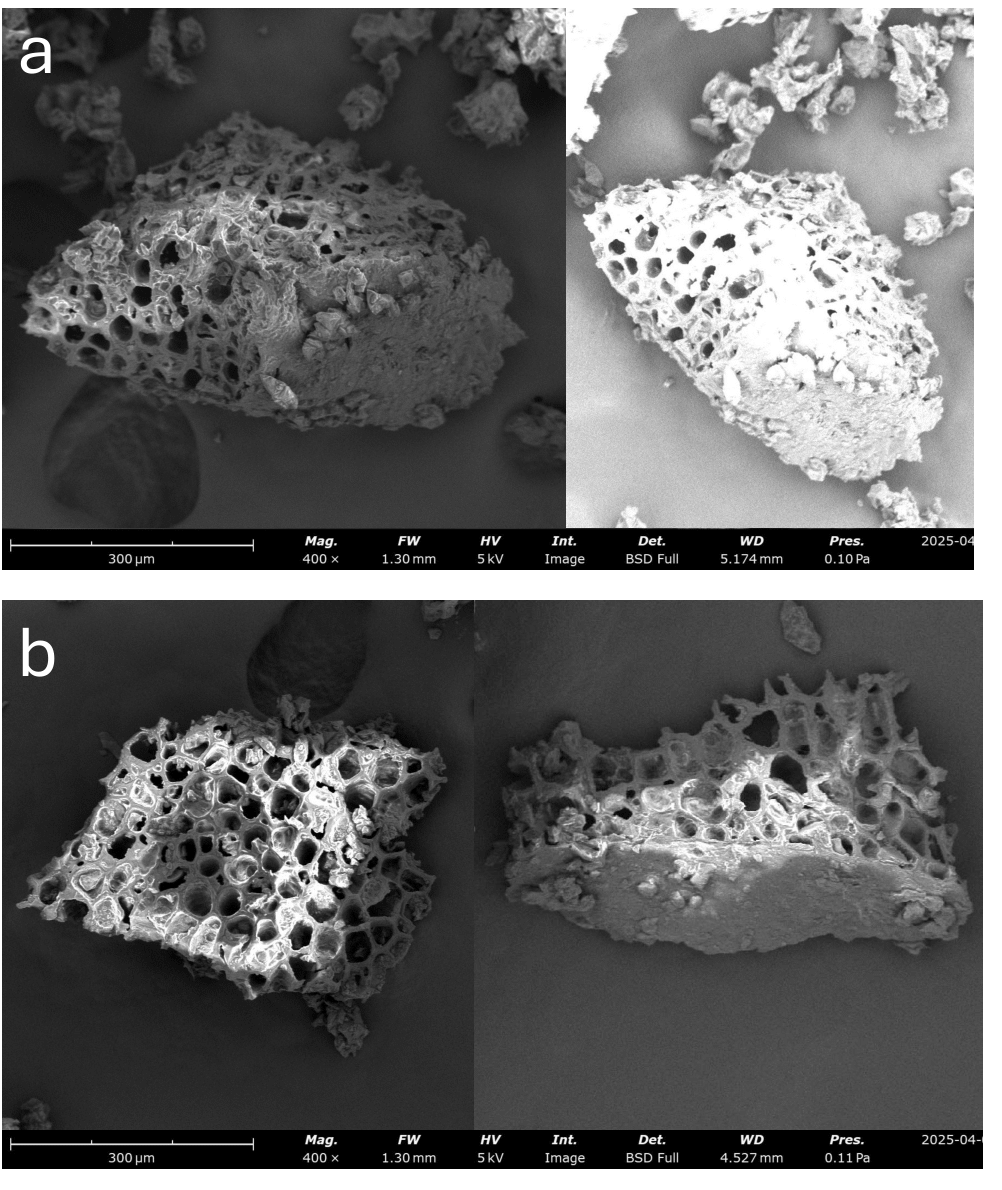

We examined fine and coarse ground medium roast coffee powder under a Scanning Electron Microscope (SEM). Fine grounds have smaller, more uniform particles with smoother surfaces and less visible porosity. Coarse grounds show rougher and more irregular surfaces, and more visible pores (See Figure 1).

The Role of Wall Friction

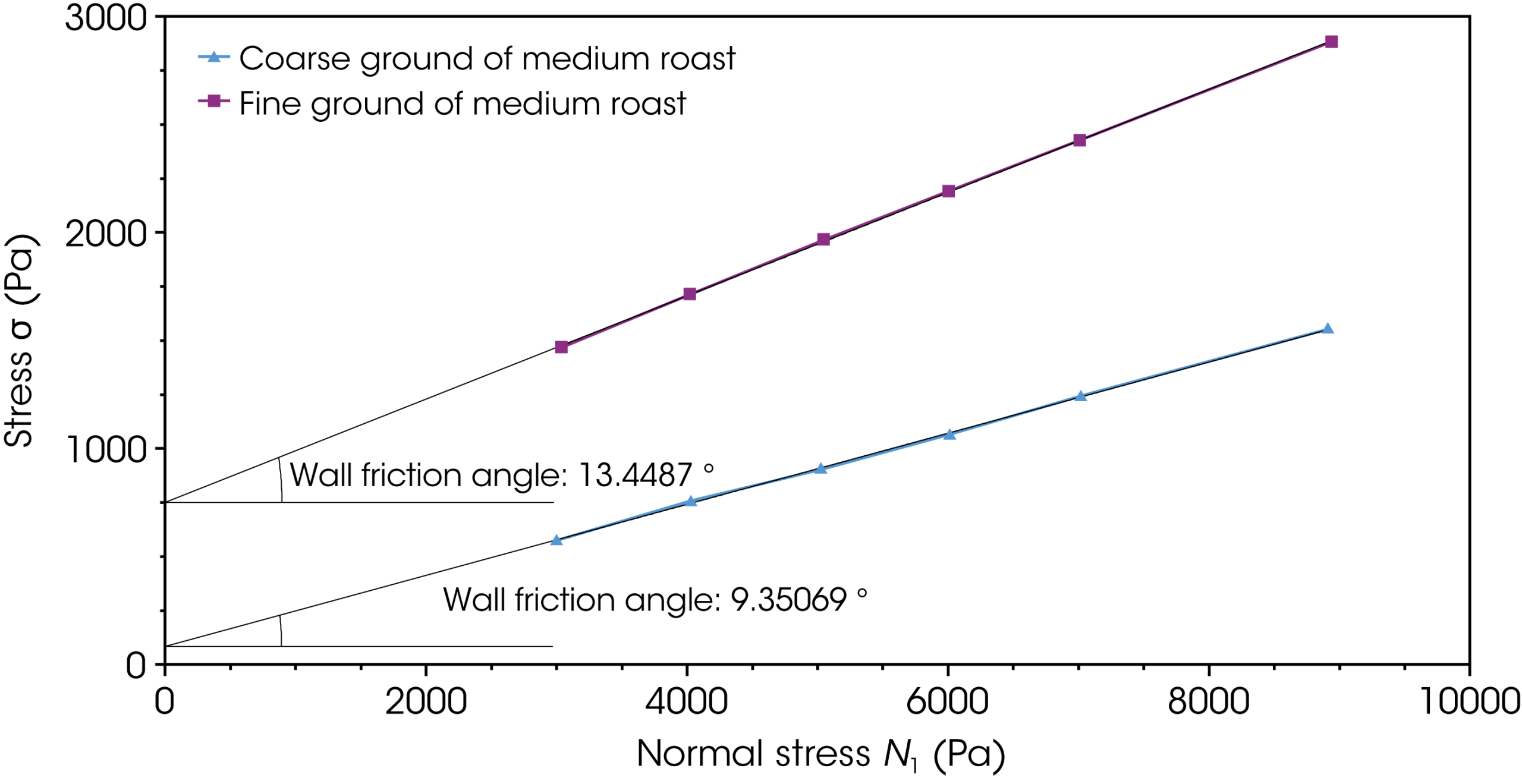

Wall friction measures the angle at which a powder will start to slide against a surface. Figure 2 shows that the angle of wall friction with stainless steel is higher for fine ground coffee compared to coarse ground coffee.

Wall friction significantly impacts various stages of coffee processing in a coffee machine. Higher wall friction in fine grounds can lead to slower and less consistent flow from the hopper to the doser, potentially causing clogging and uneven dosing. During tamping, fine grounds resist movement more strongly against the portafilter walls, resulting in uneven pressure and inconsistent puck formation. Conversely, coarse grounds with lower wall friction form a less compact puck, which can cause channeling and uneven extraction. Understanding these properties allows for adjustments in grind size, tamping pressure, and compression techniques to optimize each stage of the coffee-making process, ensuring a consistent and high-quality brew.

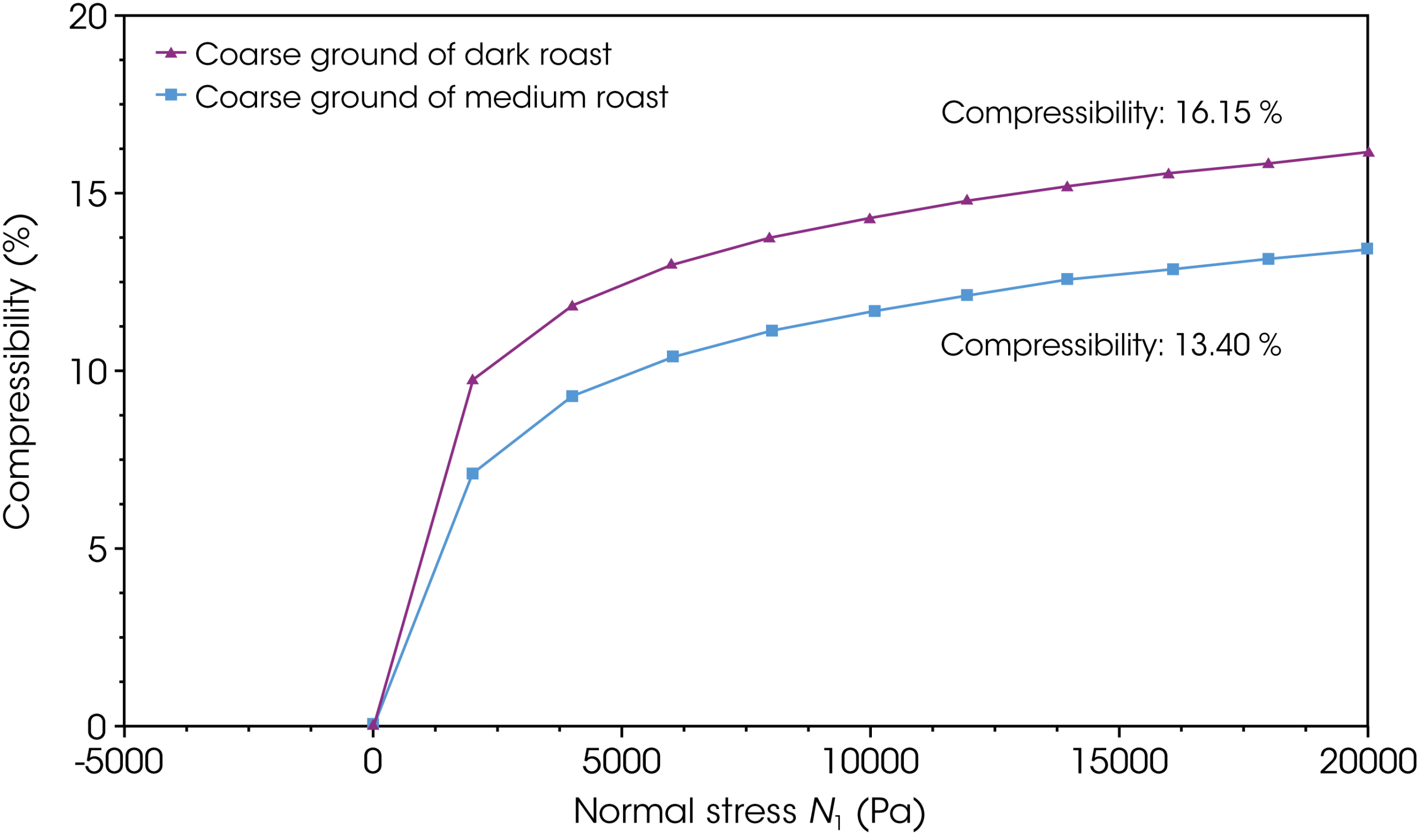

Compressibility and Dosing / Filling

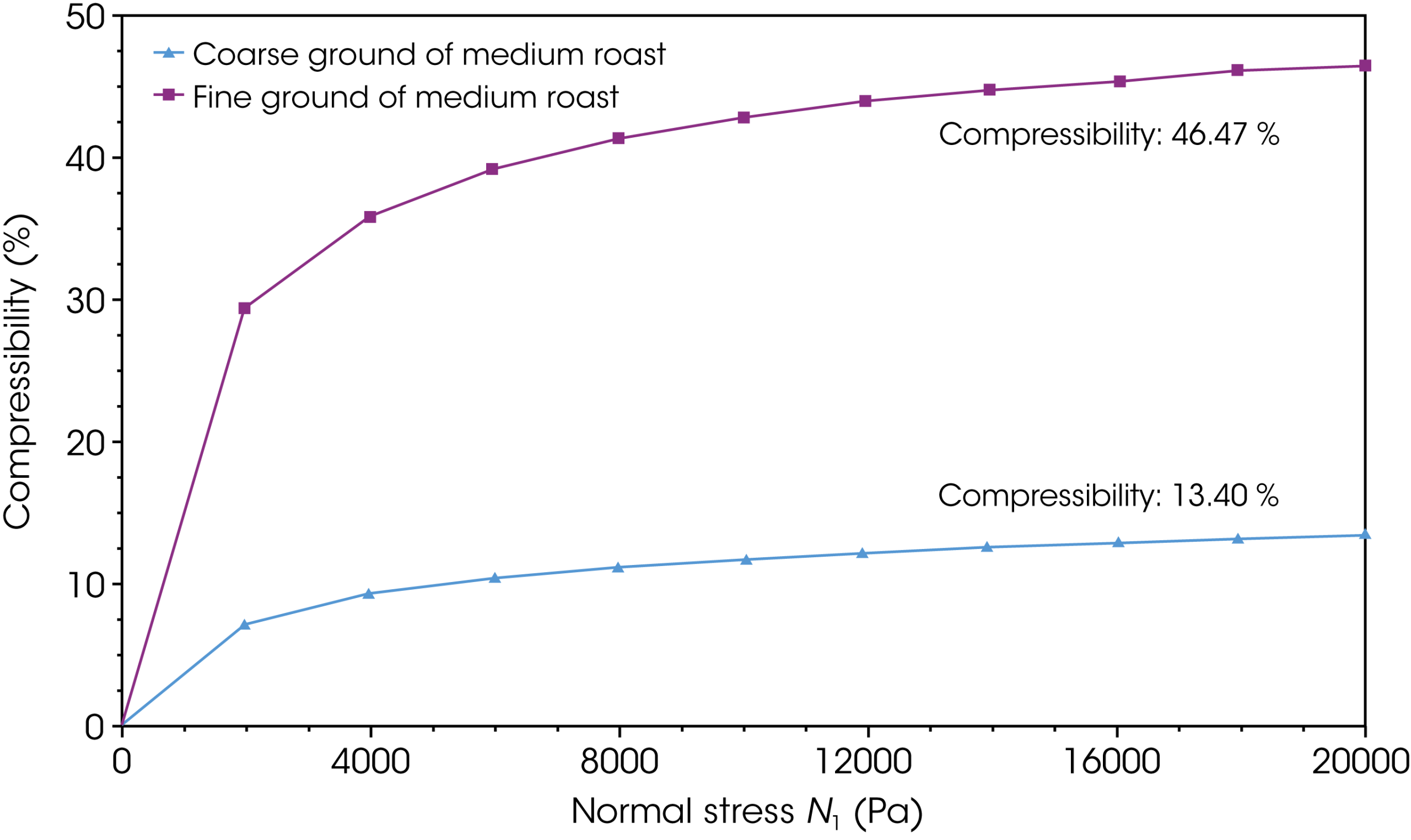

We observed that the compressibility of fine ground coffee is significantly higher compared to coarse ground coffee (See Figure 3). This increased compressibility impacts dosing and filling processes, as fine powders pack more densely and require precise control to ensure consistent dosing. The higher compressibility means fine grounds settle more easily, potentially leading to variations in the amount of coffee dispensed.

When the compressibility of fine ground coffee is significantly higher than that of coarse ground coffee, it affects both tamping and brewing processes. Fine grounds, being more compressible, pack tightly under pressure, creating a denser puck. Additionally, the higher compressibility of fine grounds can slow down water flow, increasing contact time and potentially leading to over-extraction, which can make the coffee taste bitter. Conversely, coarse grounds, with lower compressibility, allow for faster water flow and shorter contact time, often resulting in a lighter, more balanced brew.

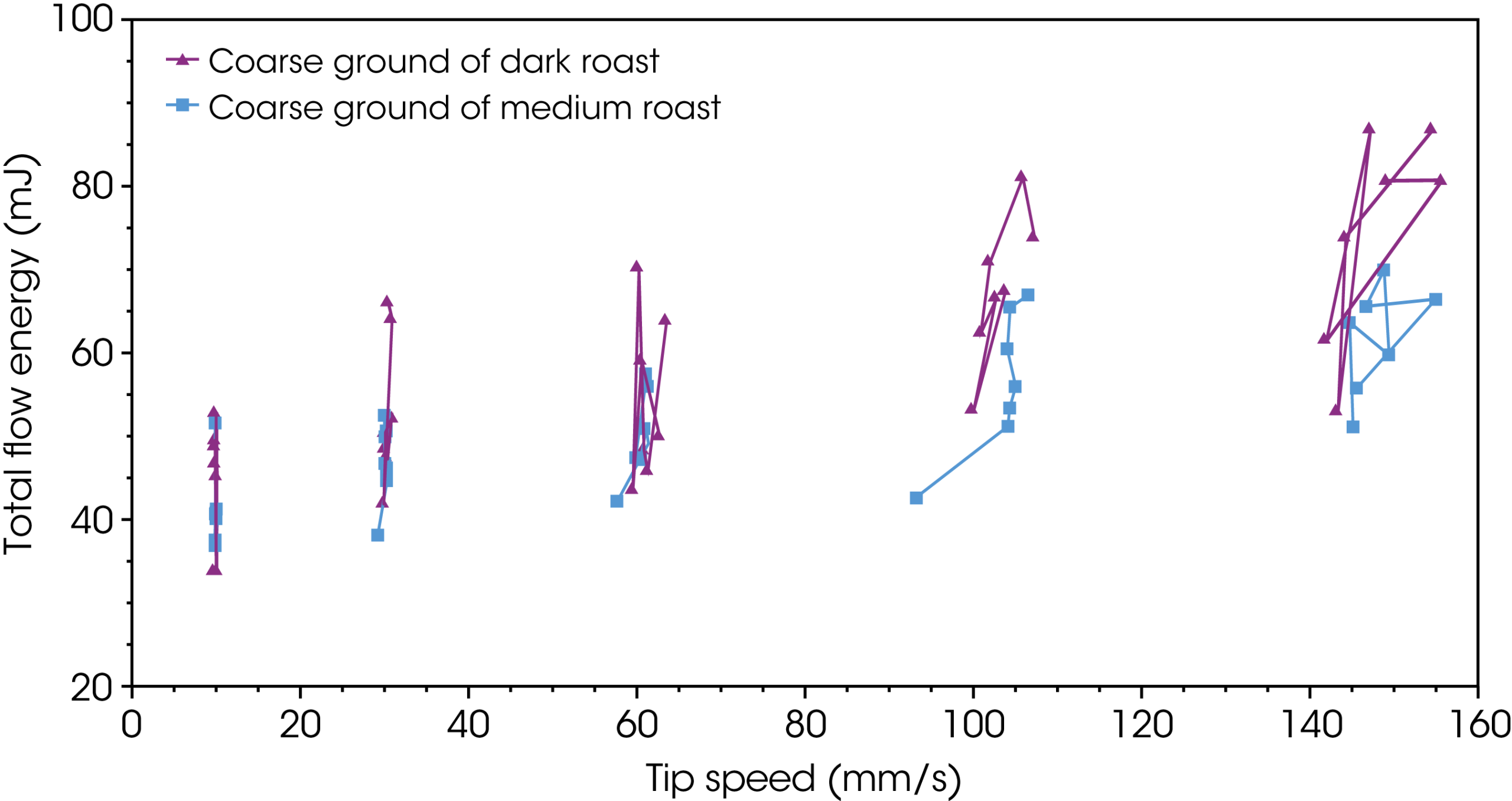

Tamping: Confined Flow Energy and Compression

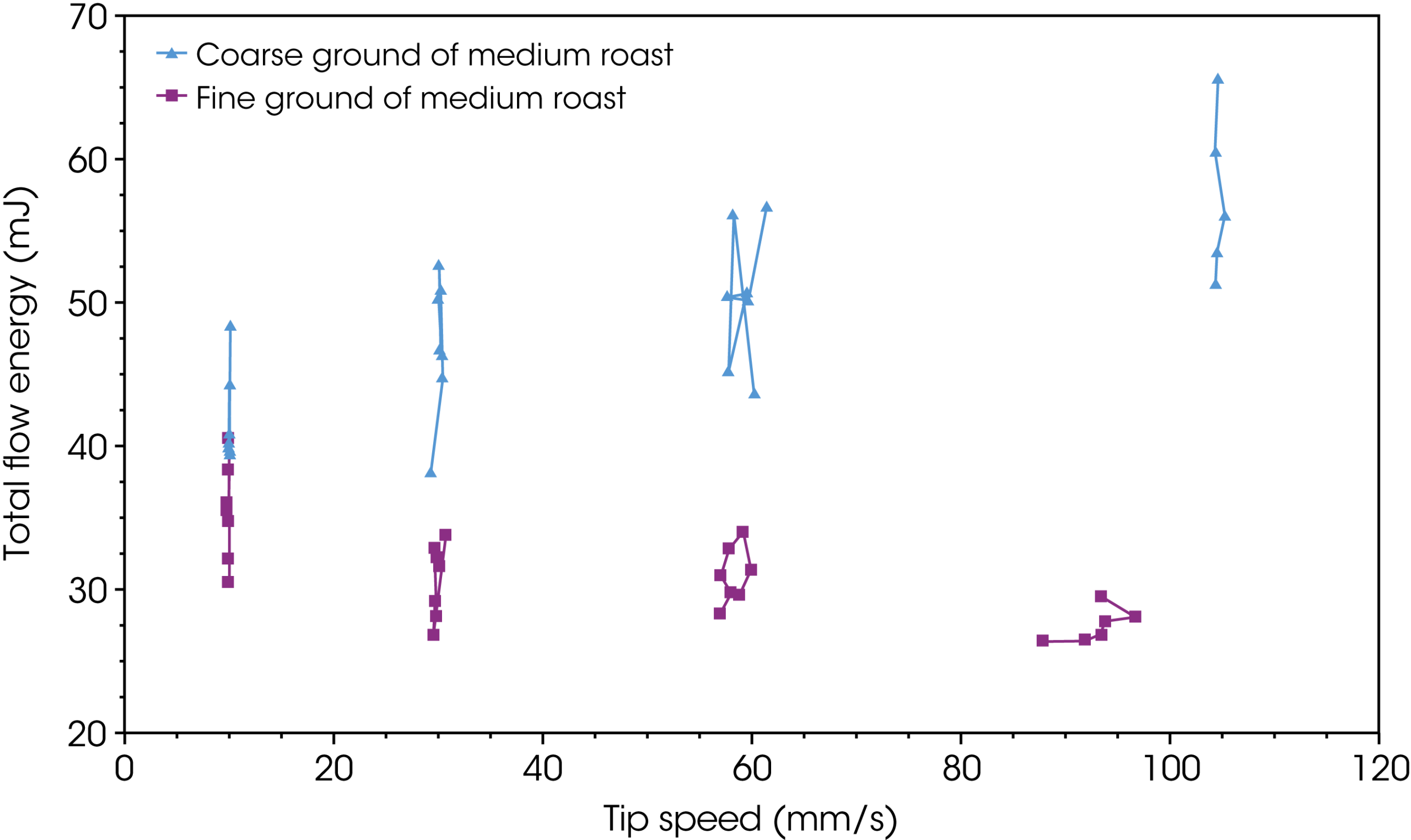

Powder movement during tamping or puck forming is influenced by confined flow energy. The confined flow energy results revealed an intriguing pattern: for coarse ground coffee, the confined flow energy increases with tip speed of the rotor, while for fine ground coffee, it decreases with tip speed (See Figure 4).

This behavior can be attributed to the influence of cohesion in fine ground coffee. Higher tip speeds help break down the cohesive forces between particles, leading to improved flowability and reduced resistance to flow. For coarse ground coffee, as the tip speed increases, the energy needed to overcome inertia and move the particles also increases. The rise in confined flow energy at higher tip speeds indicates that coarse grounds require more force to be tamped effectively, similar to powder pressed in a portafilter.

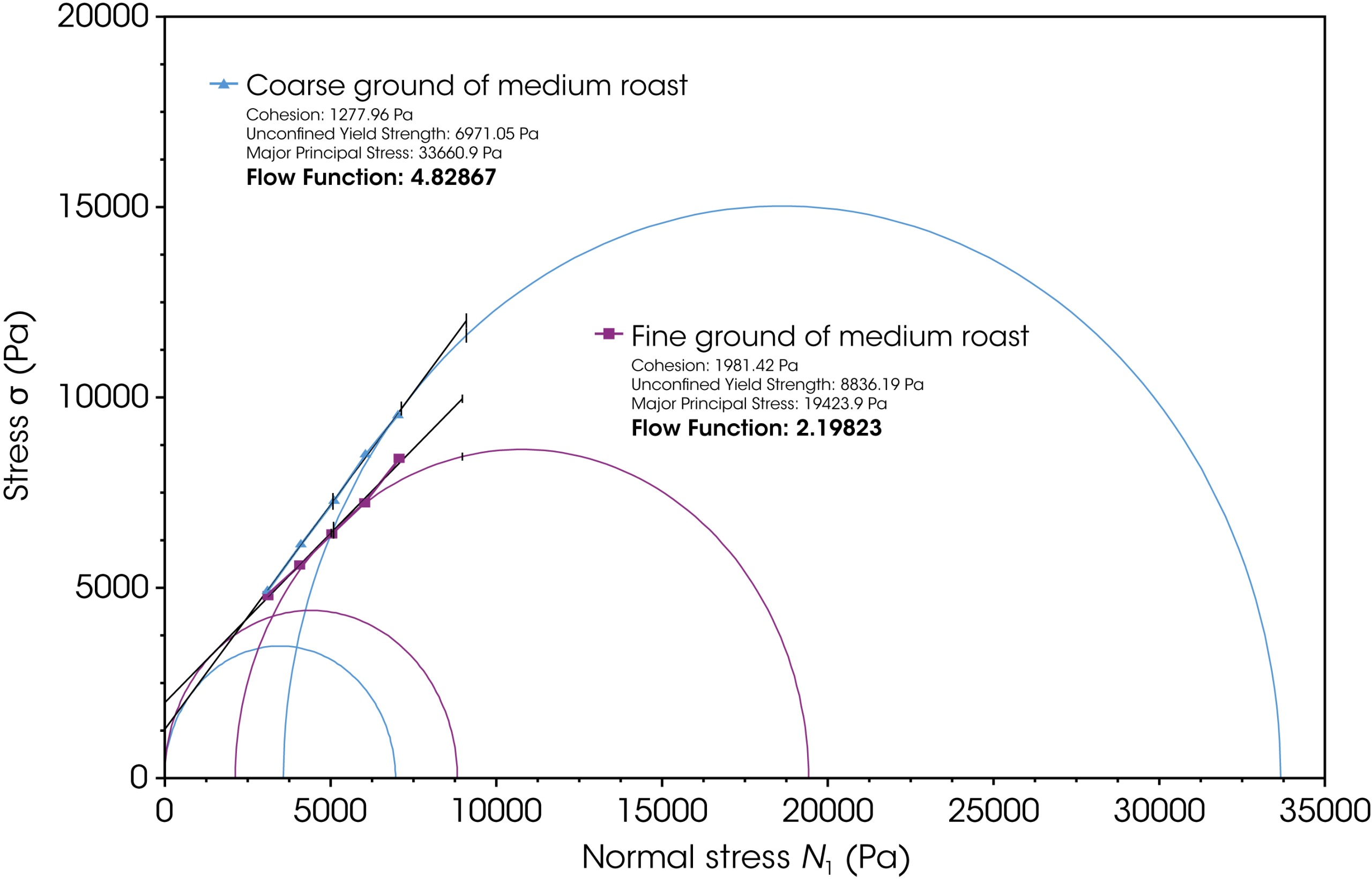

Brewing: Flow Function and Cohesion

Then, we compared the flow function and cohesion of fine and coarse ground coffee (see figure 5). As expected, fine ground coffee showed lower flow function and higher cohesion. For fine ground coffee powders, the flow function falls within the cohesive region (flow function values between 0 and 4), while for coarse ground coffee powders, it is in the easy flowing region (flow function values between 4 and 10). The lower flow function indicates that fine powders are more resistant to flow, while higher cohesion means that the particles stick together more strongly. These properties can affect the brewing process, leading to differences in extraction efficiency and flavor profile.

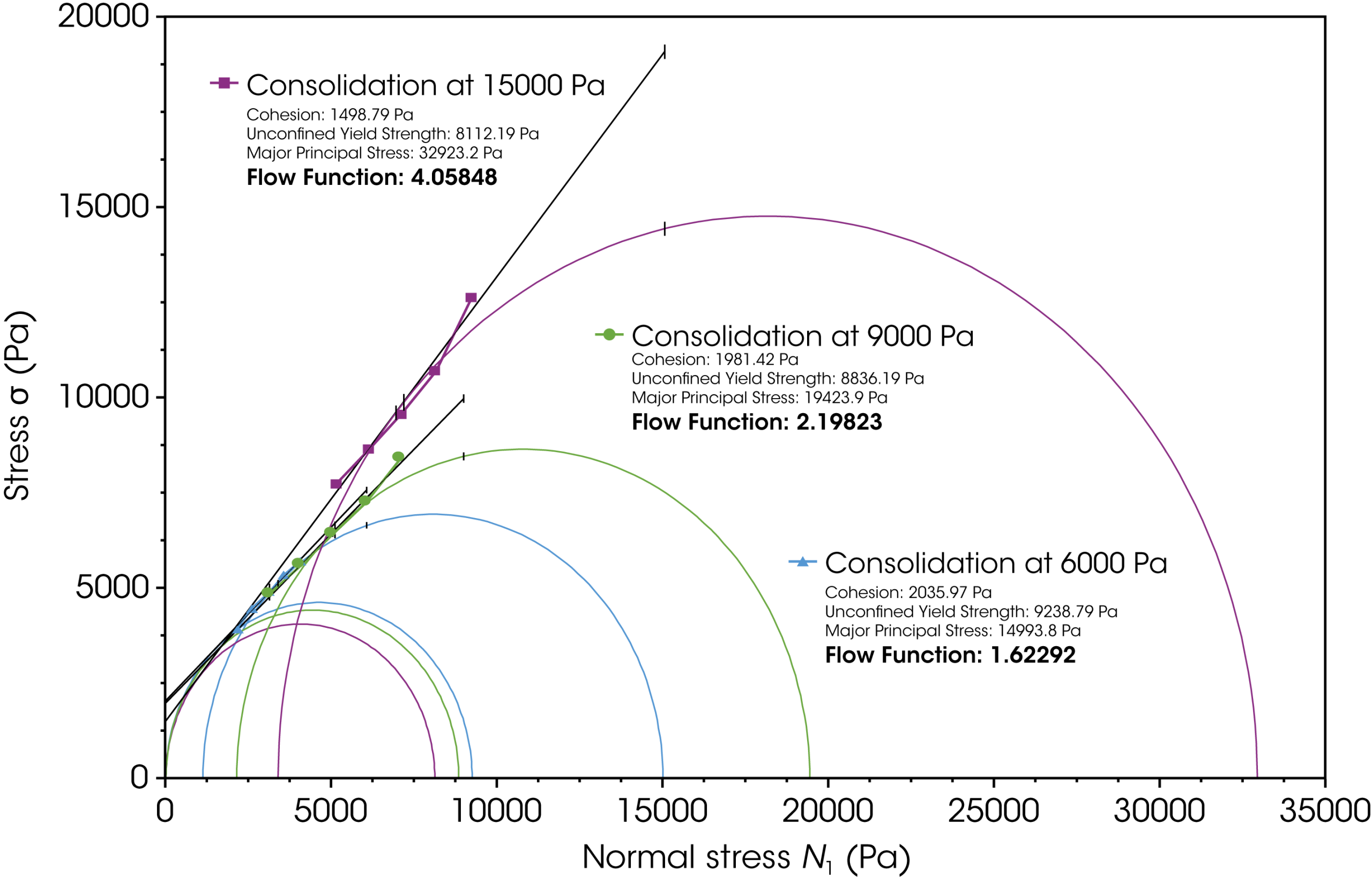

Shear flow testing measures cohesion and flow function by applying a range of consolidating stresses to a powder bed and measuring the shear stress at the point of incipient flow. Cohesion reflects the internal strength of the powder and flow function describes the relationship between consolidation stress and cohesive strength. Figure 6 illustrates that increasing consolidation stress leads to a rise in the flow function for fine powders. This increase is likely due to enhanced particle interactions and densification, causing a transition from cohesive flow to easy-flowing behavior.

This principle can be connected to coffee tamping and brewing: tamping increases the consolidation stress on coffee grounds, improving their flow function and ensuring even water distribution during brewing, which results in a better extraction and a more consistent cup of coffee.

Roast Trials: Exploring Coarse Grounds of Medium and Dark Roast Coffee

SEM images in Figure 7 show that dark roast grounds are generally more porous due to the expansion of the beans during roasting. This increased porosity is visible as larger and more numerous pores in the SEM images (Figure 7b). In contrast, medium roast grounds have fewer and smaller pores (Figure 7a).

When comparing the compressibility of medium and dark roast coffee, dark roast coffee beans, being more porous and more brittle due to longer roasting, exhibit higher compressibility, making the powder easier to compact. Medium roast coffee beans, retaining more structure and moisture, are less brittle and compressible (see Figure 8).

In Figure 9, we observe that the confined flow energy of dark roast coffee is slightly higher, possibly due to its more irregular shape, as seen in SEM images, and increased surface oil content.

In conclusion, the journey from bean to brew is a fascinating exploration of coffee powder rheology. Whether you’re grinding fine or coarse, medium or dark roast, each variation brings unique properties that influence the flavor and texture of your coffee. From the smooth surfaces of fine grounds to the porous nature of dark roast, every detail matters. So next time you sip your coffee, remember the science behind the perfect brew. Happy brewing!

Other Resources

- Blog – Advance Formulation Performance with Rheology Studies

- Blog – Rheology Theory and Applications

- Blog – Viscometer vs Rheometer: Discover Why a Rheometer Offers More Than Just Viscosity Measurement

- Application Note – Predicting Performance of Pharmaceutical Lotions Through Rheological Characterization

- Product – Discovery Core Rheometer