Overview

TA Instruments are used in research around the world across diverse fields and applications. Our blogs share industry insights, expert ideas, and real-world discoveries made with our instrumentation. Check back frequently for new blogs with up-to-date information and inspiration.

Filter by Technique

Filter by Applications

06/02/2025

Coffee lovers know that the grind size and roast degree of coffee beans can significantly impact the flavor and texture of their favorite beverage. But did you know that these factors also affect the rheological properties of coffee powders?

05/30/2025

In the world of pharmaceutical formulation and development, the ability to precisely characterize the rheological behavior of drug delivery systems is critical to ensuring efficacy, stability, and processability.

05/21/2025

Whether it’s the viscosity of hydrogels (for wound care or tissue regeneration) or the yield stress of topicals (like acne or antifungal creams), pharmaceutical manufacturers rely on rheology to monitor and eradicate defects in every batch, ensuring that when the treatment reaches the patient, it remains safe and effective.

05/16/2025

Innovation in materials science is a continuous pursuit, driven by the demand for lighter, stronger, more durable, and more reliable components. This is especially critical in the aerospace and defense industries, where materials must perform reliably under extreme conditions—including intense mechanical stress, wide temperature fluctuations, and long-term environmental exposure.

04/24/2025

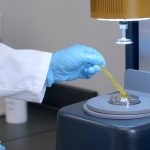

ITC is the most sensitive method for characterizing binding interactions, revealing critical attributes like drug efficacy and stability. But without proper mixing, ITC data is unreliable and unusable. Great ITC experiments start with correct mixing.

04/18/2025

Polymer rheology plays a critical role in understanding the flow behavior and viscoelastic properties of polymers across the supply chain. Whether in polymer manufacturing, compounding, conversion, or recycling, precise rheological measurements are essential for optimizing processing conditions, ensuring product quality, and preventing defects.

04/10/2025

Will your paint stick to the wall or drip off? Does your low-fat cream cheese have the same texture as a full-fat version? How will new ingredients affect your formulation’s texture and application, especially as environmental conditions change? Rheology offers invaluable insights that help researchers, developers, and engineers across numerous industries optimize their products for performance and customer satisfaction.

04/04/2025

The development of biopharmaceuticals demands precise thermal stability characterization to ensure efficacy, safety, and manufacturability. As the industry shifts toward high concentration biologic formulations and subcutaneous delivery methods, the need for innovative DSC solutions becomes increasingly critical.

03/31/2025

In battery development, precise rheological measurements are critical for optimizing material performance, ensuring uniform coatings, and enhancing conductivity. Whether working with cathode, anode, or electrolyte materials, selecting the right rheometer is essential. TA Instruments offers two industry-leading solutions: the Discovery Core Rheometer and the Discovery Hybrid Rheometer. This guide helps battery scientists determine which instrument best suits their needs.

03/11/2025

Pharmaceutical research and discovery rely on accurate characterization of molecular interactions to develop effective and safe drugs. Isothermal Titration Calorimetry (ITC) is a gold-standard technique that provides critical insights into binding affinity, thermodynamics, and stoichiometry—essential components in Structure-Activity Relationship (SAR) studies.