Insights to Improve Cosmetic Formulation, Processing, and Quality Control

TA Instruments | Waters have put together a lab package designed specifically for your cosmetics and personal care lab. Combining these instruments allows your lab to expedite candidate selection, streamline product development and deliver insight into the viscoelastic properties of your materials.

Streamline product development from candidate selection to measuring sensory perception

Save time and money by expediting candidate selection

Define the relationship between formulation changes and their effect on product stability, sensory perception, and customer acceptance criteria with conclusive rheology and DSC measurements. Quantifying these properties allows you to build internal metrics, identify key performance criteria for successful products, and filter undesirable products early in the formulation stage before moving to expensive sensory panels.

Measuring the viscosity and viscoelastic properties of your materials will help deliver insight to answer questions such as:

- Is there enough elasticity so that the product does not separate, and the active ingredients remain suspended?

- Is my active ingredient sufficiently and uniformly distributed throughout my product?

- What is the best container or dispensing mechanism for my product?

Predict consumer perception and product behavior in relevant environments

Our wide range of environmental systems and accessories allows you to characterize solution stability and material behavior with simultaneous visual techniques (i.e. microscopy, Rheo-Raman, and SALS) or under extreme conditions, such as humidity and pressure environments.

Cosmetic labs frequently use the HR tribology accessory to measure the coefficient of friction, which correlates with tactile and sensory perception. The powder accessory is uniquely able to measure powder flowability and shear properties all in one accessory, providing a complete picture of powder behavior.

Food scientists frequently use the following rheometer accessories in their labs:

Application Examples

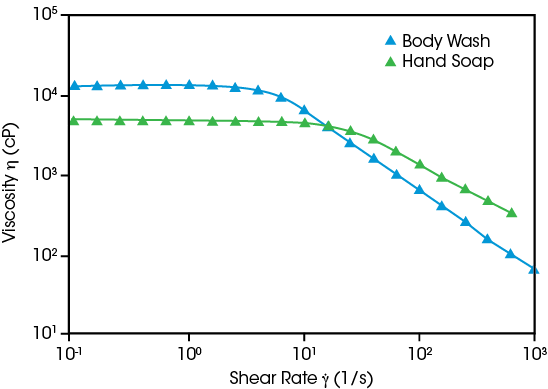

Optimized Flow Behavior

The liquid soaps above show similar viscosities at a medium shear rate but expanding the measurement range shows key differences. Compared to hand soap, body wash shows higher zero-shear viscosity, flowing more slowly at rest. At high rates, body wash is less viscous, more easily spread. Basic viscometers may not detect these differences, but consumers are highly attuned to flow behavior and instinctively reject a body wash that drips off the washcloth or a hand soap that doesn’t coat properly.

Discovery Core Rheometer Benefits:

- Measure real-world flow behavior impacting application, dispensing and stability

- Streamline routine testing with simplified, guided operation

- Accurately measure creams, gels and soft solids with textured plates preventing slip error

- Characterize a wide range of materials, from low-viscosity serums to soft-solid lipsticks

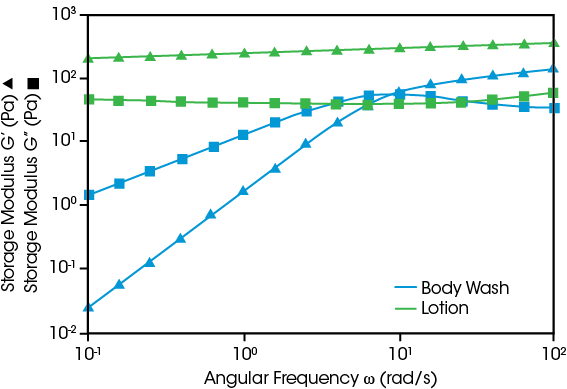

Viscoelasticity and Emulsion Structure

While viscosity measurements describe flow behavior, oscillatory measurements dive deeper into the underlying microstructure. Frequency Sweep measurements show body wash to be a viscoelastic liquid which flows after a short time as indicated by the frequency of the crossover of Storage Modulus G’ and Loss Modulus G”. Lotion shows Storage Modulus dominating across frequency, indicating an elastic structure that maintains emulsion stability over time.

Discovery Core Rheometer Benefits:

- Measure real-world flow behavior impacting application, dispensing and stability

- Streamline routine testing with simplified, guided operation

- Accurately measure creams, gels and soft solids with textured plates preventing slip error

- Characterize a wide range of materials, from low-viscosity serums to soft-solid lipsticks

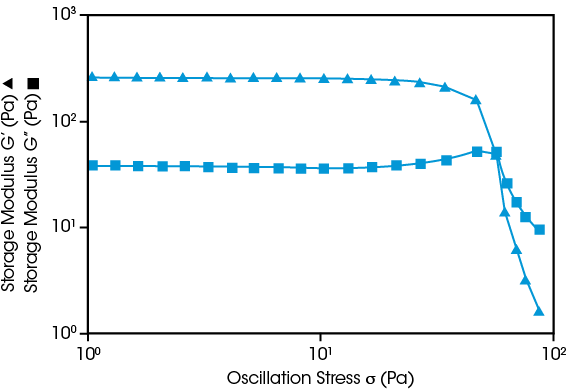

Yield Stress and Dispensing

Oscillatory measurements of lotion in the linear viscoelastic region show elastic behavior reflecting the emulsion stability, but this structure must be readily deformed in order to dispense and apply to the skin. Increasing the applied oscillatory stress shows the Storage Modulus break down and drop below Loss Modulus, transitioning for solid-like to liquid like behavior. The stress required for this change represents a yield stress, which should be optimized to ensure successful dispensing from packaging.

Discovery Core Rheometer Benefits:

- Measure real-world flow behavior impacting application, dispensing and stability

- Streamline routine testing with simplified, guided operation

- Accurately measure creams, gels and soft solids with textured plates preventing slip error

- Characterize a wide range of materials, from low-viscosity serums to soft-solid lipsticks