Keywords: TGA, Smart-Seal, pan, Discovery, TZero™

TB104

Abstract

Many advanced materials, for example battery and pharmaceutical, are highly reactive with atmospheric components, including oxygen and water vapor. Not only handling but testing of such materials must be done in an inert environment, such as a glovebox. Installing test instrumentation in gloveboxes, however, is counterproductive on many levels. Therefore, testing methods that do not require a glovebox have advantages over those that do. Thermogravimetric analysis (TGA) is an essential tool in the study of materials, providing information on stability, composition, and degradation characteristics. This application note introduces a new type of hermetic TGA sample pan: the TGA Smart-Seal Pan. This pan, using shape-memory technology, automatically opens inside the inert TGA furnace environment, thereby providing testing capabilities without the need of a glovebox.

Introduction

Performing experimental studies on highly atmospheric-sensitive samples usually requires the use of a glovebox. In many cases, not only is sample preparation performed in the glovebox, but the analytical instrument is located there as well. Installing an analytical instrument in a glovebox is counterproductive on several levels. It takes up valuable space that could be used for other purposes such as sample preparation. It is cumbersome and time consuming to perform tasks with the instrument that would otherwise be trivial if the instrument was in an ambient environment. This includes cleaning and taring pans and placing loaded pans on the autosampler. Finally, servicing of the instrument may require opening the glovebox, adding to the overall downtime because of the need to regenerate the inert atmosphere.

This application note introduces the TGA Smart-Seal Pan, which is a pan for use in all TA Instruments™ Discovery™ Series II TGAs. The pan offers a fully hermetic seal, which can be punctured once loaded into the inert environment of the TGA furnace, thereby eliminating the need to install the TGA in a glovebox. Data is presented demonstrating the quality of the seal.

With the TGA Smart-Seal Pans, samples are sealed in the pans in a glovebox or other inert enclosure as normal, and then transferred to the TGA autosampler, where they can sit for extended periods of time prior to experiment execution. Because the pan opens once it is in the TGA furnace and an inert environment has been established, exposing the sample to atmospheric levels of oxygen or water vapor can be avoided. This contrasts with pans that are punctured on the autosampler and then loaded into the furnace. Some materials are sensitive enough that even a brief exposure to atmospheric conditions will have an impact on sample integrity and data quality.

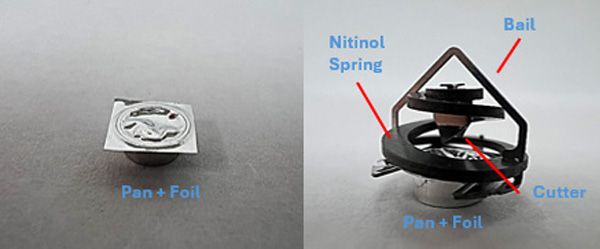

The TGA Smart-Seal Pan, shown in Figure 1, operates by a nitinol shape-memory spring. The sample is hermetically sealed in a TA Instruments TZero Aluminum Pan with an aluminum foil lid. The shape-memory spring has a cutter mounted to it. Once loaded into the TGA, the furnace is purged briefly to reestablish inert conditions. Upon heating, the shape-memory material will actuate at approximately 55 °C, driving the cutter into the aluminum foil lid and thereby opening the pan.

TGA Smart-Seal Pan Workflow

Today, workflow and improvements that can be leveraged to improve productivity are highly sought. With the TGA Smart-Seal Pans, a simple and convenient three-step workflow provides reliable atmospheric protection and accurate TGA analysis:

- After taring the empty pan, foil lid, and bail assemblies on the TGA, the pan and foil lid are transferred into a glovebox for sample loading. The filled pan is sealed with aluminum foil using the standard press for TA Instruments TZero Pans. After sealing, the sample is hermetically isolated inside the pan, which can now be transferred out of the glovebox.

- Sealed pans loaded with sample are inserted into the bail assemblies. The pan and bail assembly can then be placed in the autosampler tray of a Discovery Series II TGA equipped with EGA or IR furnace and the tray installed into the TGA. (Note: for TGAs without autosamplers, the complete pan and bail assembly can be placed directly onto the autoloader.)

- TGA tests on a single or a series of samples can now be performed in a standard Discovery Series II TGA. Autosampler sequencing can be used to automatically analyze up to 25 samples in this way.

Maintaining standard instrument operation leads to a vastly improved workflow, unlike the more complex glovebox configuration.

Experimental

To demonstrate the seal quality of the TGA Smart-Seal Pans, desiccant granules (W. A. Hammond Drierite Company, Ltd.) were dried in a TGA installed in a glovebox at 150 °C for two hours and then placed in the TZero Aluminum Pans and sealed with the aluminum foil seals. Desiccant materials naturally absorb water vapor and change color from blue to pink in the process. These sealed samples were then loaded into a Discovery SA unit, installed under normal laboratory conditions outside the glovebox, and exposed to various levels of humidity for four hours at 25 °C.

The Discovery SA is a thermogravimetric-style instrument designed to monitor sample weight while exposing it to controlled levels of temperature and humidity. Thus, absorption of water vapor will be detected as a weight change and an indication of a compromised seal.

The samples were then left on the autosampler and re-checked two weeks later to determine if any moisture had entered in the intervening time while the samples were sitting on the autosampler at ambient conditions.

Results and Discussion

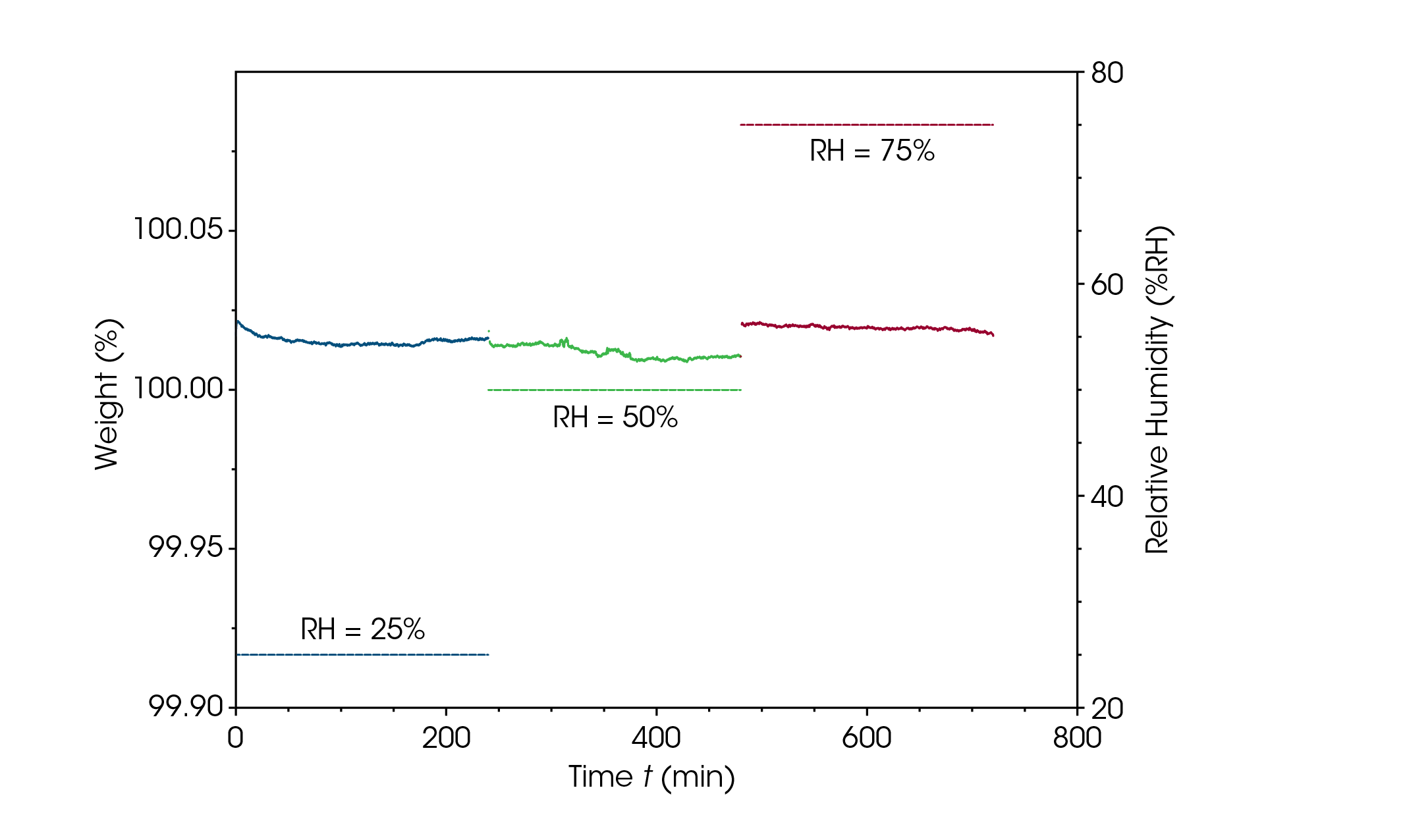

Figure 2 shows a typical test on a desiccant granule at 25 °C and relative humidity levels of 25 (blue), 50 (green), and 75% (red). The data is plotted as Weight % versus Time. At each RH level, the data shows no indication of any leakage – the weight is stable to within the drift of the instrument, indicating that the seal is of high quality.

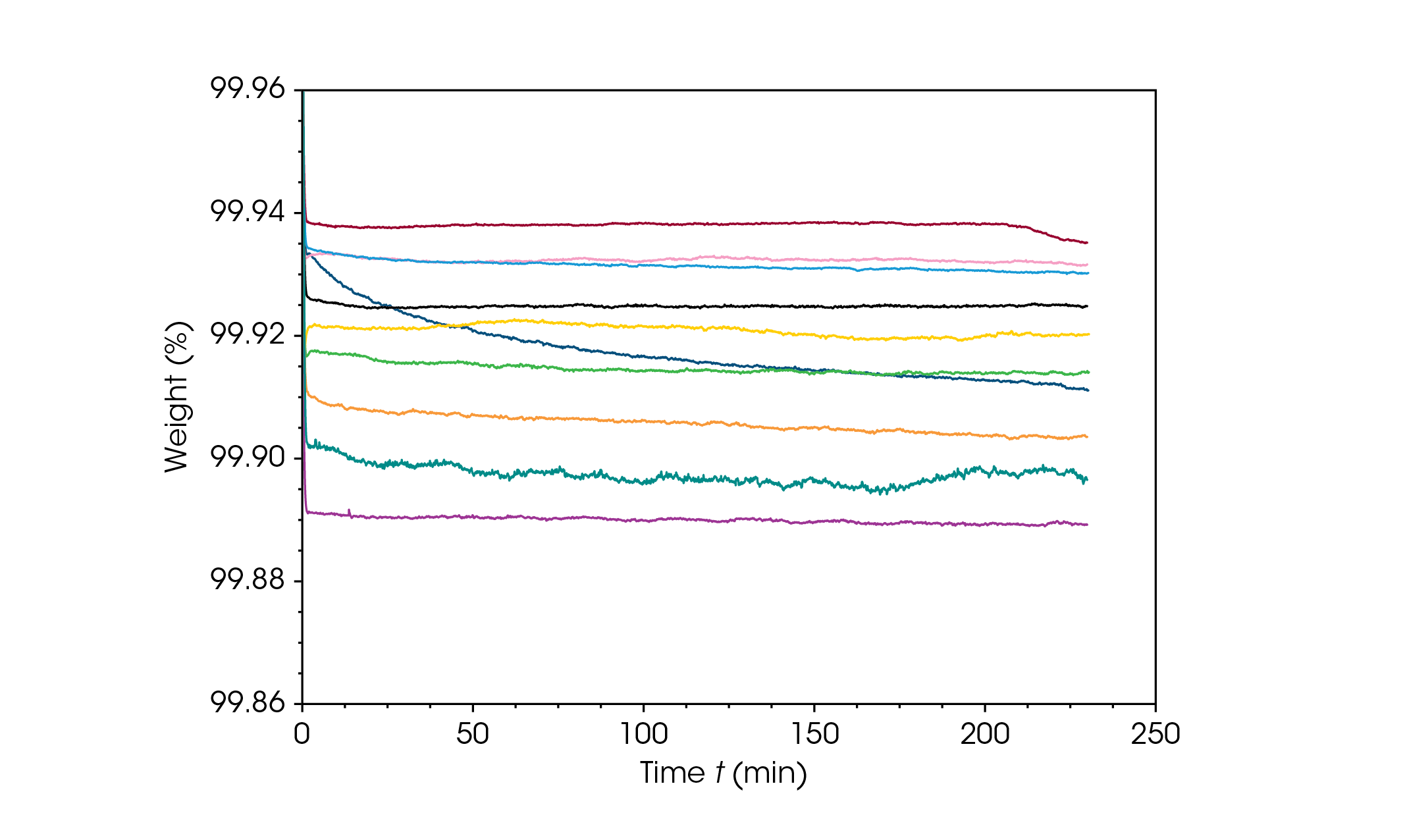

Figure 3 shows an overlay graph of ten samples tested at 50% relative humidity for approximately four hours. Again, no indication of leakage is apparent for any sample. One sample shows a small drift downward of about 0.02%, likely due to stabilization at the test conditions. Table 1 is a comparison of the preweigh measured weight and the weight at the time of the experiment. Preweigh is a function available in TRIOS™ Software that allows for sample masses to be weighed once they are placed on the autosampler. Then, when the sample is loaded later for analysis, the weight recorded at the beginning of the experiment can be compared to the pre-weight value to see if any changes have occurred to the sample while sitting on the autosampler. The tare repeatability of the Discovery SA is ±5 μg, meaning that multiple loading/unloading of pans will show similar weights, on average, to within ±5 μg. Except for sample #2, all weights are within the tare repeatability of the unit.

For the testing shown in Table 1, samples were on the autosampler for varying amounts of time, up to 48 hours. Table 2 shows a reexamination of the weights of these samples two weeks after initial testing. The data indicate that, again, to within the tare repeatability error, no water vapor has entered into the pans. Thus, the quality of the TGA Smart-Seal Pan is of very high quality.

As a final check, the aluminum foil lid for sample #1 was pierced and the sample left to sit on the autosampler for 16 hours. The sample mass had increased by 732 μg to 11.297 mg, which is an approximate 7% increase. The rate of water uptake here is 0.44 μg/min.

Table 1. Comparison of pre-weight and start of test weight values for the ten sample runs shown in Figure 3

| Run # | Pre-Weigh Wgt (mg) |

Start of Test Wgt (mg) |

% Diff | μg Diff |

|---|---|---|---|---|

| 1 | 10.565 | 10.564 | 0.009 | 1 |

| 2 | 8.299 | 8.293 | 0.072 | 6 |

| 3 | 8.095 | 8.09 | 0.062 | 5 |

| 4 | 9.303 | 9.301 | 0.021 | 2 |

| 5 | 8.535 | 8.534 | 0.012 | 1 |

| 6 | 12.578 | 12.579 | -0.008 | -1 |

| 7 | 9.031 | 9.03 | 0.011 | 1 |

| 8 | 16.299 | 16.304 | -0.031 | -5 |

| 9 | 14.975 | 14.976 | -0.007 | -1 |

| 10 | 3.915 | 3.915 | 0.000 | 0 |

Table 2. Comparison of pre-weight values and weight values at two weeks for the ten samples shown in Figure 3

| Run # | Pre-Weigh Wgt (mg) |

2 Week Check (mg) |

% Diff | μg Diff |

|---|---|---|---|---|

| 1 | 10.565 | 10.562 | 0.028 | 3 |

| 2 | 8.299 | 8.298 | 0.012 | 1 |

| 3 | 8.095 | 8.094 | 0.012 | 1 |

| 4 | 9.303 | 9.304 | -0.011 | -1 |

| 5 | 8.535 | 8.54 | -0.059 | -5 |

| 6 | 12.578 | 12.579 | -0.008 | -1 |

| 7 | 9.031 | 9.034 | -0.033 | -3 |

| 8 | 16.299 | 16.305 | -0.037 | -6 |

| 9 | 14.975 | 14.98 | -0.033 | -5 |

| 10 | 3.915 | 3.918 | -0.077 | -3 |

Conclusions

This application note introduced the TGA Smart-Seal Pan and the improved workflow it offers to those researchers studying highly atmospheric sensitive materials. The experiments detailed in this note were designed to test the seal quality of the TGA Smart-Seal Pan. The tests involved the seal quality against water vapor tested with a desiccant sample. The seal quality was shown to be very high. Water vapor molecules have a dimension of about 0.275 nm.1 Other atmospheric components such as nitrogen or oxygen molecules are larger at 0.305 nm and 0.299 nm, respectively.2 Thus, the expectation is that the seal will also perform well at preventing these components from entering the pan.

Acknowledgement

This note was written by Gray Slough, Ph.D.

For more information or to request a product quote, please visit www.tainstruments.com to locate your local sales office information.

TGA Smart-Seal, TA Instruments, Discovery, TZero, and TRIOS are trademarks of Waters Technologies Corporation.

Click here to download the printable version of this application note.