Keywords: Continuous Casting, Mold Powder, Slag, Steel Industry, Viscosity, Viscometry

TPP031

Abstract

Viscosity of mold powders is of critical importance for controlling lubrication, infiltration of the flux and preventing strand break-out during continuous casting. TA Instruments’ new high temperature rotational viscometer VIS 413 allows to easily, safely and economically measure this key parameter in a wide temperature range. The viscosity data are complementary to measurements of the melting and solidification behavior using heating microscopes like the HM 867.

Mold powders are a broad group of materials used to cover the liquid steel meniscus during continuous casting of steel.

Continuous casting transforms molten metal into solid on a continuous basis and includes a variety of important commercial processes. These processes are the most efficient way to solidify large volumes of metal into simple shapes for subsequent processing. Most basic metals are mass-produced in continuous casting processes, including over 500 million tons of steel, 20 million tons of aluminum, and 1 million tons of copper, nickel, and other metals each year.

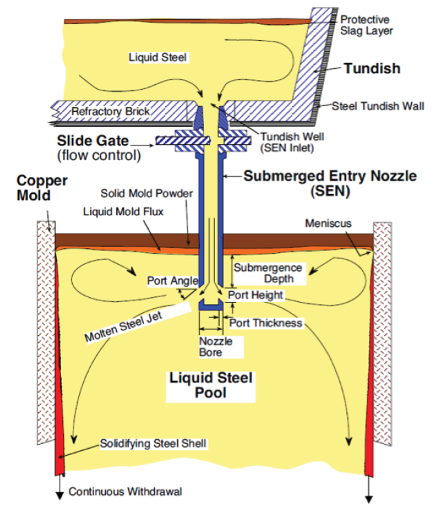

The continuous casting process for steel is shown in Fig.2. Molten steel flows from a ladle, through a tundish with attached nozzle into the mold. The liquid steel must be protected from exposure to air: if not, then oxygen will react to form detrimental oxide inclusions in the steel.

Once in the mold, the molten steel solidifies against the water-cooled walls of a bottomless copper mold to form a solid shell. Molten mold powder can infiltrate between the copper mold and steel shell and provides lubrication. The mold is oscillated vertically to prevent sticking of the steel shell to the mold walls. Driving rolls, below the copper mold continuously withdraw the shell from the mold at a rate or “casting speed” that matches the flow of incoming metal. So, the process ideally operates in continuous, steady state. The most critical part of the process is the initial solidification at the meniscus. This is found at the point where the top level of the liquid steel contacts the mold, and the shell formation starts. At this point the surface of the final product is created, and defects such as surface cracks can form.

Casting powders play an important role in the surface quality of the metal products and in the overall efficiency of the continuous casting process. These powders have a critical influence on the heat transfer from the metal to the mold, the solidification process, and the mold lubrication. The powder, which is continuously fed on the surface of liquid metal pool during casting, melts first and then flows into the gap between mold wall and solidified metal shell.

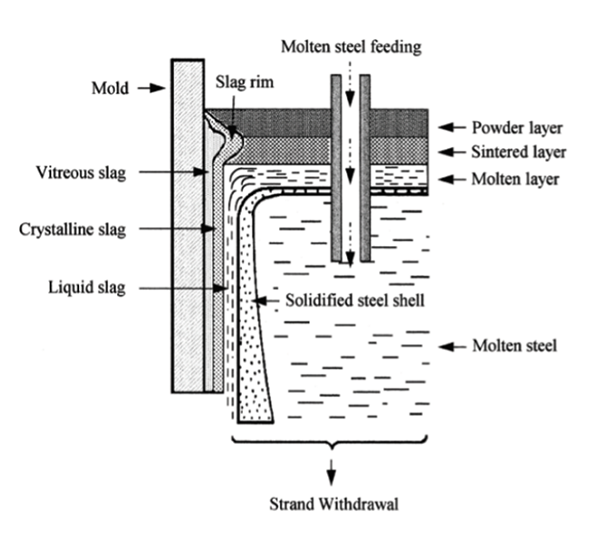

The powder on the meniscus generally consists of four layers (Figure 3): an un-reacted, un-melted powder layer on top; a sintered, semi-reacted intermediate layer; a zone in which the mold powder is melting and, finally, a molten layer directly on the molten steel. Lubrication is almost completely provided by this liquid molten powder and depends on many factors. Generally, mold powders with lower melt viscosity and/or melting temperature tend to provide lower friction, better lubrication properties, and thus prevent sticking. Insufficient lubrication – and heat removal from the steel – can result in break-out of the strand, i. e. rupturing of the cast steel shell and catastrophic loss of the inner molten metal contents.

As shown in Figure 3 the mold powder forms according to its state of aggregation and physical state three different layers between the steel shell and the copper mold. The properties of the slag layers determine the main functions of strand lubrication and heat transfer to the mold.

Mold powders that are directly exposed to molten steel will experience instantaneous heating very far from equilibrium conditions. Powders usually have a glassy behavior in this case. As the molten flux cools down and partially recrystallizes, phase separation may occur. Chemical composition and physical properties of the mold powder determine to which extend crystallization or vitrification occur in the layers. Crystals are favorable and wanted for a homogeneous and controlled heat transfer to the mold. The remaining molten phase with changed composition has a different viscosity than the entire mixture. That changes the lubrication and infiltration properties of the flux.

Experimental

With TA Instruments high-temperature rotational viscometer VIS 413, the viscosity of molten mold powders can be determined accurately as function of temperature and atmosphere. It provides a precise method to quantify and compare the lubricating properties of the mold powder and data to optimize its composition and dosing for a production process. The solidification point or range of the mold powder is also readily apparent from the measurement, which provides information about the behavior close to real-life conditions. Additionally. viscosity measurements with used mold powders can be performed providing valuable insights about the influence of impurities on the flow and crystallization behavior.

For the below shown viscosity measurement of mold powder disposable ceramic crucibles and rotors were used in the VIS 413. Compared to the same parts made of platinum alloys this avoids the time-consuming cleaning after an experiment. Additionally, the inert ceramic rotor and crucible allow measuring viscosity of used mold powders with metallic constituents which would potentially alloy with metallic instrument parts.

Complete atmosphere control is also provided in the VIS 413. It can be used to simulate oxygen free and reducing conditions in addition to regular measurements in air. The vacuum and gas tight design of the VIS 413 also protects users from gases that are released upon heating by the sample. Some types of mold powders release fluorine compounds and other potentially hazardous components. Even such materials can be safely analyzed in the VIS 413.

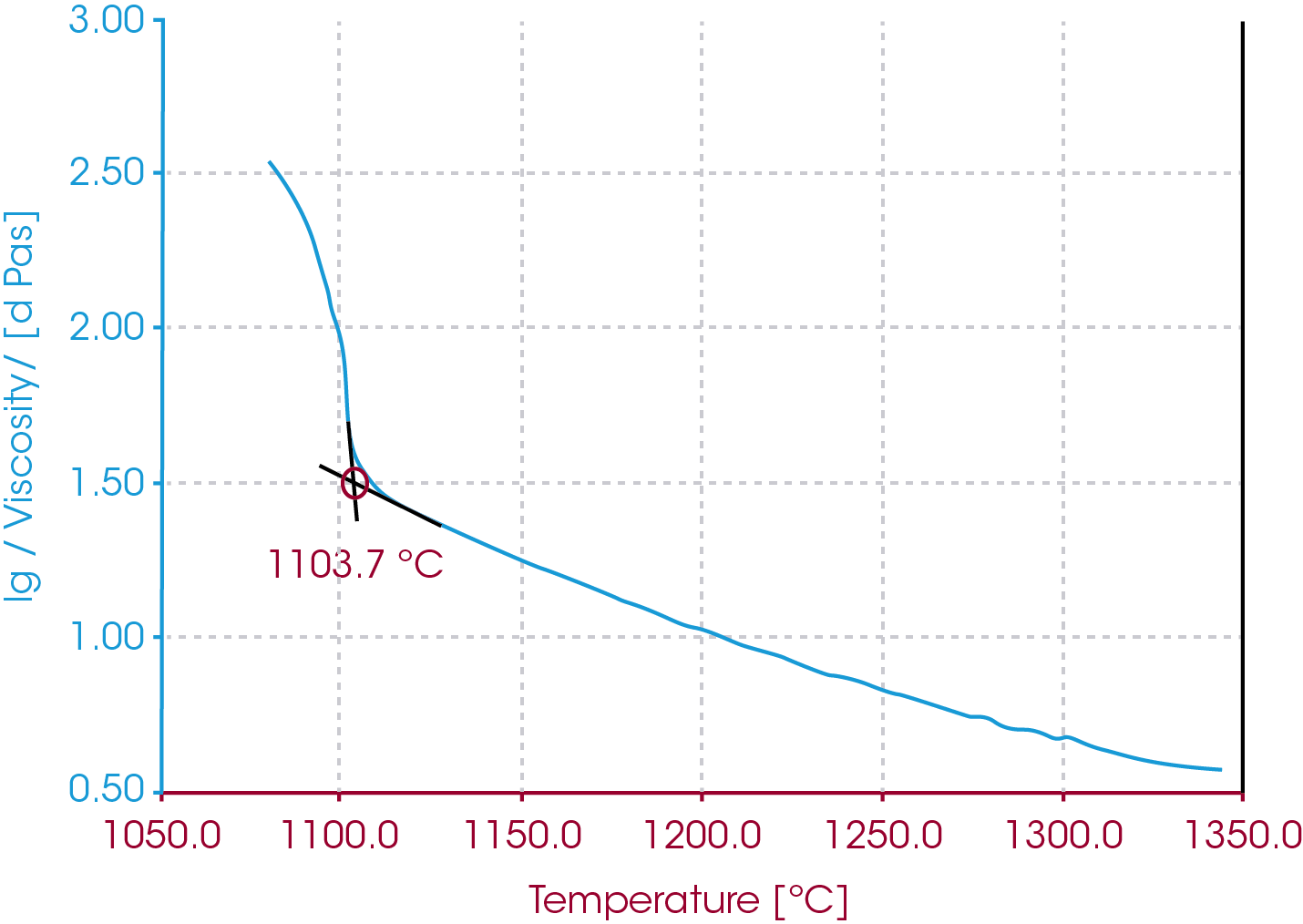

The graph in Figure 4 shows a viscosity measurement of a mold powder sample. The sample was heated to 1350 °C and then measured during controlled cooling with a cooling rate of -5 °C per minute. The onset of solidification is apparent in the sudden increase of viscosity at 1103.7 °C. The viscosity could be accurately determined in the entire temperature range and is displayed in dPa·s on a logarithmic scale, ranging from 3.72 dPa·s to 31.99 dPa·s at the onset of solidification.

Conclusion

Mold powders can have many components and a complex composition: Within the operational window of the casting process, a simplification of the chemical composition and raw material choice is desired. Depending on the process parameters such as casting speed, size, material and desired chemical processes, different types and components of mold powders can be chosen.

In addition, the constituents and properties of mold powder are sometimes not fully known. Hence, it is important to be able to quantify key properties such as viscosity experimentally. This knowledge allows for optimization of the production process beyond trial and error and the behavior of mold powder batches can be predicted from experimental data.

The casting process itself is complex and depends on a multitude of variables: processes in the mold are not fully understood and essential material properties of the solidifying steel are mostly unknown. It is difficult and sometimes nearly impossible to measure the process conditions in the mold and to characterize the various material properties at casting temperatures. Therefore, essential data on the casting process and the material properties, especially at high temperatures, are needed to evaluate the process and to develop more reliable models.

Experimental work is crucial for a further understanding of powders and process: successful casting is a consequence of the choice of optimum casting conditions and mold powder properties. For all these reasons, fundamental research on mold powders and the casting process is essential to increase knowledge, to improve the casting process and to be able to cast novel steel grades. With extensive knowledge about material properties of mold powders, the production process is easier to design, control and optimize.

Acknowledgement

This application note was written by Christian Skawianczyk at TA Instruments.

Click here to download the printable version of this application note.