Keywords: dynamic mechanical analysis, glass transition, modulus, molecular spectrum, thermoplastic polymers

TA307

Abstract

ASTM International D 648 is a standard method for evaluating the softening temperature of materials, commonly referred to as the Deflection Temperature Under Load (DTUL) or Heat Distortion Temperature (HDT). It is shown that Dynamic Mechanical Analysis (DMA) provides the traditional DTUL but also provides dynamic mechanical structure information unattainable by DTUL.

Introduction

Structural polymers and composites are often tested to find a softening temperature, above which, the material is unable to support a load (1). This temperature is known as the heat distortion temperature. The American Society for Testing and Materials International (ASTM) has a series of standards for evaluating this parameter, including D 648 (flexure), D 1043 and D 1053 (shear), and D 1525 (penetration) (2, 3, 4, 5).

In D 648, known as the Deflection Temperature Under Load (DTUL) test, a bar of rectangular cross-section is subjected to a constant flexural load (455 Pa or 1820 Pa) and heated at 2 °C/min (2). The temperature at which a certain modulus, measured by deflection (0.25 mm), is observed is taken as the DTUL. A TA Instruments dynamic mechanical analyzer (DMA) such as the DMA 850 may be used to perform this common test. Based on the dimensions of the ASTM sample, 0.25 mm is equivalent to a specific strain (0.121%). If the DMA is used in the 3-point bending mode and the force equivalent to 455 Pa is applied on a sample, then the temperature at which the DMA sample deflects by 0.121% strain is the DTUL.

The DTUL is a single-point measurement. The effect of certain molecular characteristics such as crystallinity and cross-linking affect the DTUL (1). DTUL is a bulk property of the material rather than one relating to its microscopic structure. For example, in immiscible polymer blends having two distinct glass transition temperatures, each is characteristic of one component in the blend. The DTUL test is unable to detect the two components. DTUL cannot provide information about secondary transitions due to small-scale relaxations.

The Dynamic mechanical analyzer (DMA) provides all the information that can be obtained from a DTUL standard test and much more. The DMA can discern the elastic and viscous components of deformation (6, 7). It gives a very sensitive profile of the viscoelastic properties, including storage modulus, loss modulus and tangent δ as they change with temperature. By measuring true thermoplastic material properties, the DMA is able to better assess the effects of crystallinity, cross-linking, fillers, additives, molecular weight, aging, etc. Thus, DMA provides the ability to differentiate between samples on a more fundamental basis.

Experimental

Two filled thermoplastic polymer samples, A and B, are tested in 3-point bending mode. For the DTUL, the force is held constant while the temperature is increased at 2 °C/min. The displacement indicating DTUL for each sample is monitored.

For the dynamic mechanical measurements, a frequency of 1 Hz, amplitude of 20 µm and Force Track of 130% are used. The temperature is increased at 3 °C/min from -50 to 220 °C. (There is no need to maintain the same ramp rate between the two types of experiments because the aim is to show the presence of additional information available from the DMA measurement.).

Results and Discussion

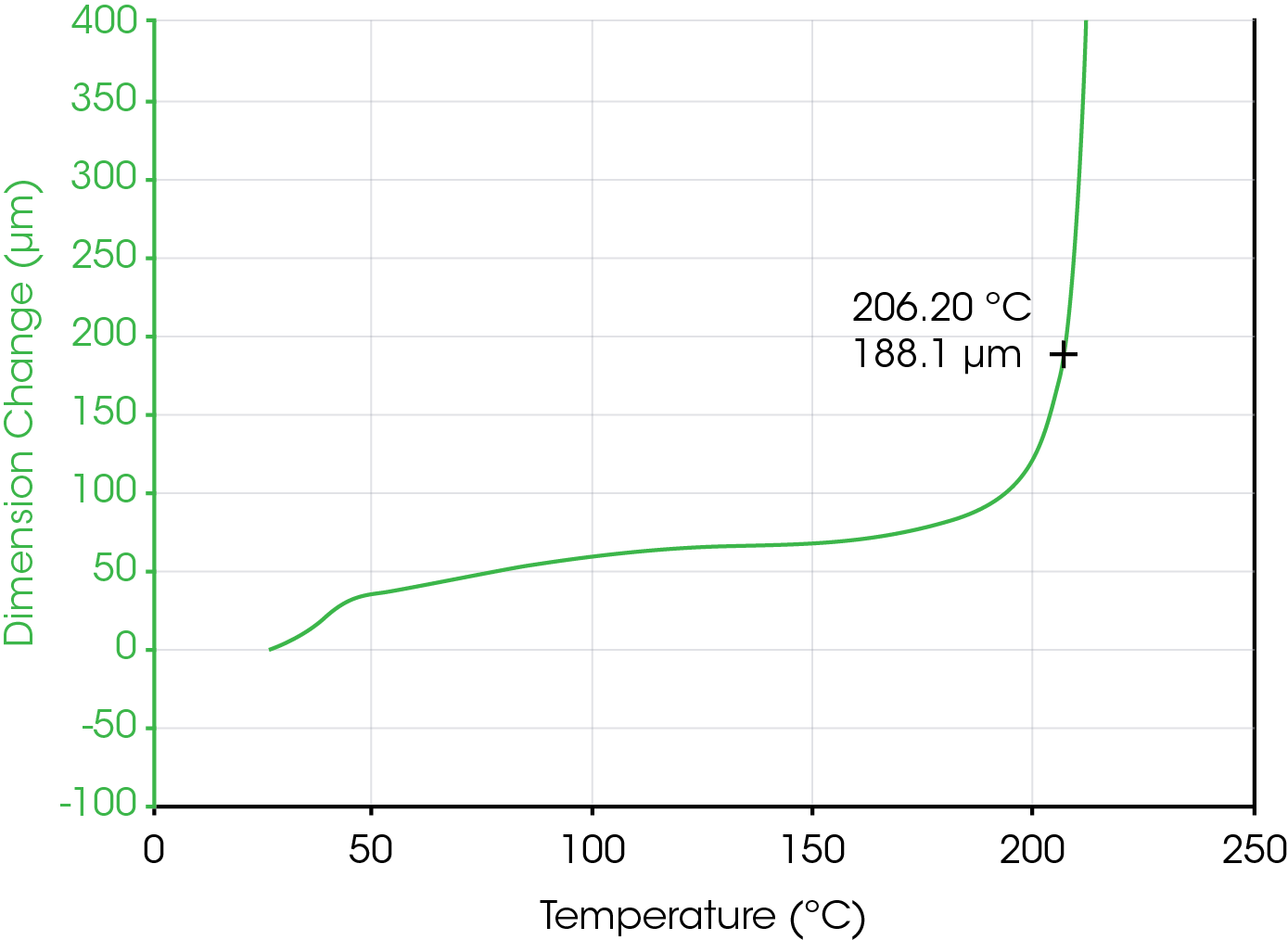

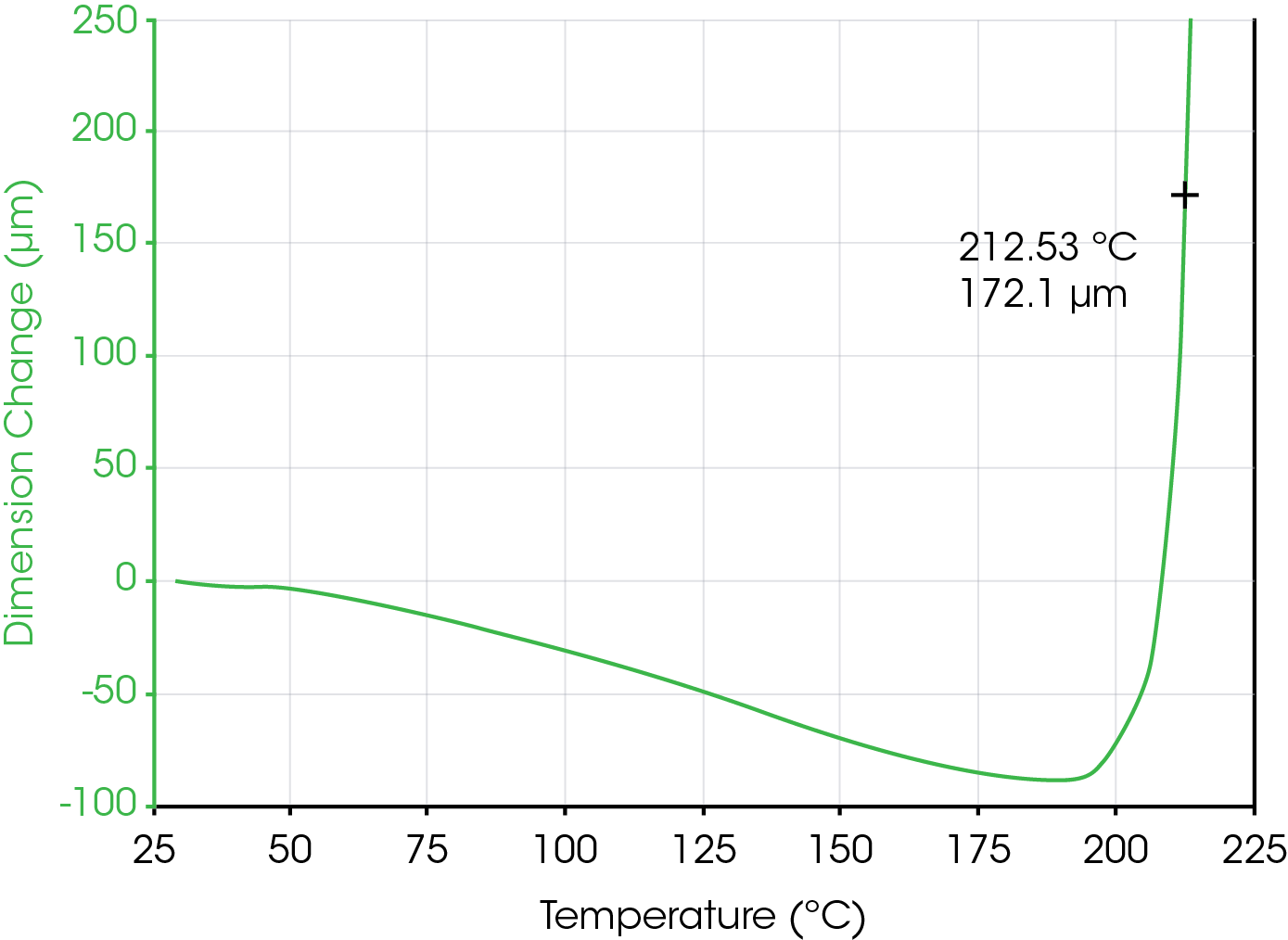

Shown in Figures 1 and 2 are the displacement profiles occurring in the samples as a function of the changing temperature in the DTUL test. The displacement at which the required strain for DTUL is achieved is different from one sample to another, based on the differences in the dimensions of those samples. But the DTUL for samples A and B are 208.2 and 212.5 °C, respectively. The precision of a DTUL measurement is typically ± 2 °C. While additional studies would have to be performed to ascertained if the difference in the DTULs of the two samples is statistically significant, given the nature of the DTUL test, it can be difficult to delineate sensitive, critical differences between two materials.

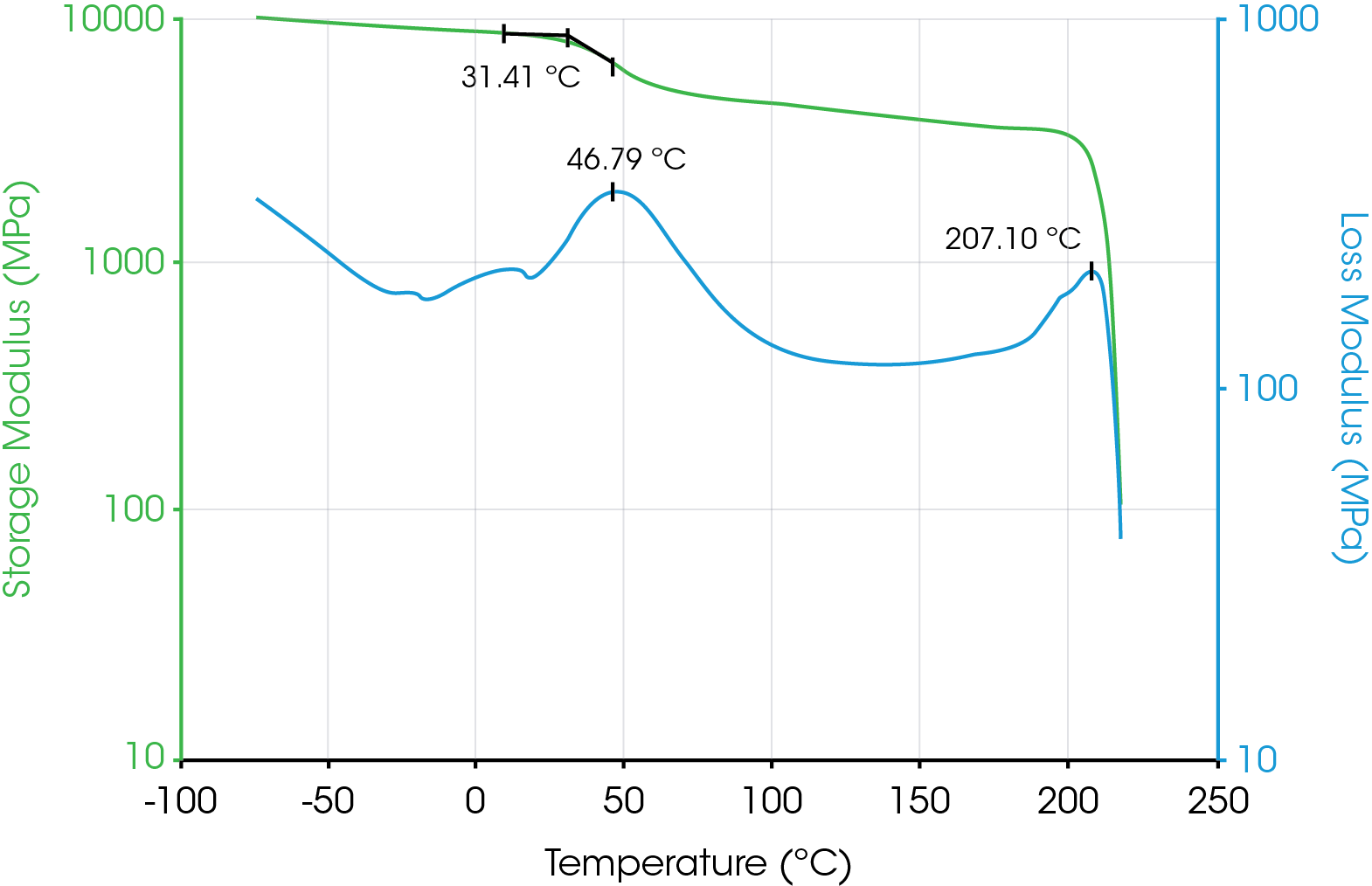

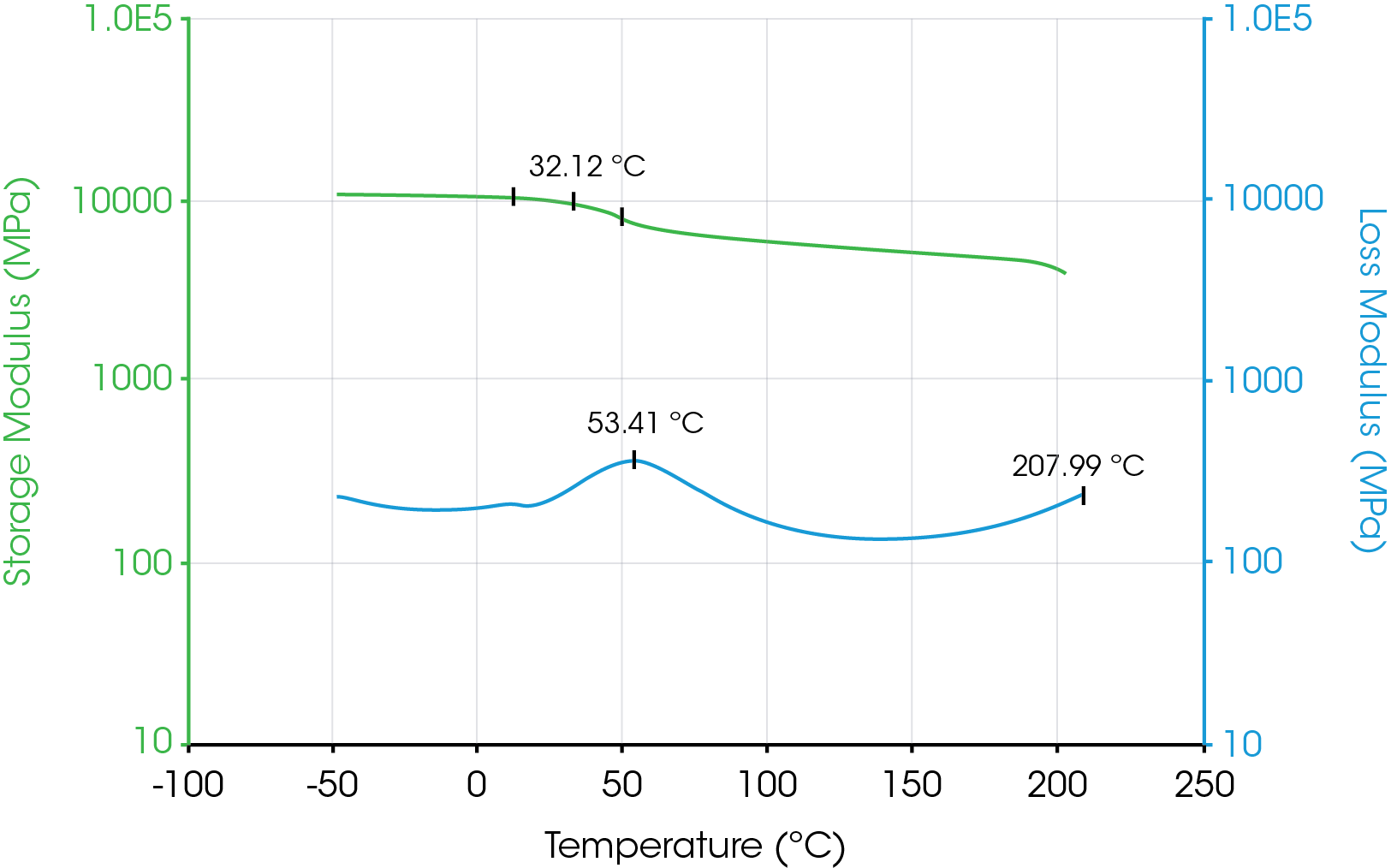

In Figure 3 and 4, the storage and loss moduli of samples A and B are shown changing as a function of temperature. In each of these figures, a glass transition temperature is noted near 50 °C by the drop in storage modulus (E’) and a peak in the loss modulus (E”). Taking the peak in loss modulus as the indicator, there seems to be a difference in the glass transition temperatures (Tg) of the two materials (47 °C for A and 53 °C for B). Furthermore, there are some additional E” relaxation peaks in A near 0 °C that are not present in B. These may be due to low molecular weight additives in B or other short-chain motions in the constituents (6).

At higher temperatures, there is a precipitous drop in storage modulus, indicating melting of the matrix material. The melting points, according to the loss modulus peak, for A and B are 207 and 208 °C, respectively. These values are very close to the DTULs of the two samples and would indicate that DTUL is only an indicator of the softening of the bulk material.

As can be observed from figure 3 and 4, sample B exhibits a higher modulus than A. This shows that apart from DTUL measurements, DMA allows users to directly compare intrinsic, viscoelastic mechanical properties of materials such as storage and loss modulus as a function of temperature, further adding value to the technique and its application.

Summary

Dynamic mechanical testing as a function of temperature is a more versatile technique in evaluating mechanical properties of materials. In the same amount of time that it takes to run a DTUL experiment, the storage and loss moduli at a variety of temperatures can be measured. As a result, properties such as Tg, secondary transitions, and melting temperature are obtained. The viscoelastic parameters are better suited for linking mechanical properties to structural and/or morphological characteristics of materials.

References

- Lawrence E. Nielsen and Robert F. Landel, Mechanical Properties of Polymers and Composites, Marcel Dekker, 2nd Ed., 1994.

- D 648, “Deflection of Plastics Under Flexural Load”, American Society for Testing and Materials, West Conshohocken, PA.

- D 1043, “Stiffness Properties of Plastics as a Function of Temperature by Means of a Torsion Test”, American Society for Testing and Materials, West Conshohocken, PA.

- D 1053, “Stiffness at Low Temperatures: Flexible Polymers and Coated Fabrics”, American Society for Testing and Materials, West Conshohocken, PA.

- D 1525, “VICAT Softening Temperature of Plastics”, American Society for Testing and Materials, West Conshohocken, PA.

- John D. Ferry, Viscoelastic Properties of Polymers, 3rd Ed., John Wiley & Sons, 1980.

- I. M. Ward and D. W. Hadley, An Introduction to the Mechanical Properties of Solid Polymers, John Wiley & Sons, 1993.

Acknowledgement

Click here to download the printable version of this application note.