Keywords: Discovery TMA 450EM, glass transition, coatings, penetration

TA450

Introduction

A thermomechanical analyzer (TMA) measures dimensional change of a sample as a function of time, temperature, and force. Heating or cooling experiments with a TMA are used to determine a sample’s coefficient of thermal expansion (CTE) and glass transition (Tg), both of which are crucial material properties.

The Discovery TMA 450

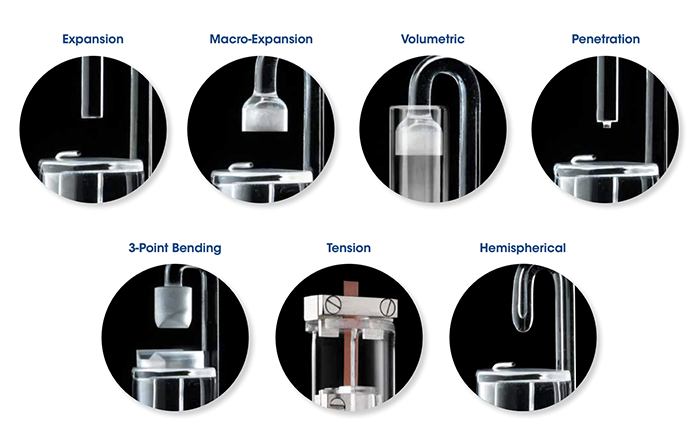

The Discovery TMA 450 is a high-performance TMA that is capable of high sensitivity and maximum versatility. This TMA can be equipped with multiple test fixtures for running many different samples and performing a variety of measurements, as shown in Figure 1 below.

This application note will describe determining the Tg of coatings on a metal panel by using the penetration probe.

Coated Panels

The degree of cure of the coating on two samples was investigated. Two panels were studied (pre-coated and pre-cured), each with a coating approximately 4 mils thick. It is known that the Tg of this coating, when fully cured, is 45 °C.

Experimental

The panel was cut into small squares that would fit on the stage of the TMA, approximately 5 mm square. The penetration probe was used for this testing, with a force of 0.1 N. The dimensional change of a coating in contact with a penetration probe will show a step change at a softening point during a thermal ramp. This is caused by added mobility of the polymer chains as they move through the glass transition. Knowing that a non-fully cured coating could have a Tg around room temperature or below, it is important to start the experiment without the probe touching the sample, so as not to prematurely penetrate the coating. The TMA 450 was equipped with an MCA 70, a mechanical cooler with a range of -70 °C to 400 °C. With the probe centered above the sample the furnace was lowered and the following method was run:

- Equilibrate -50 °C

- Set Force 0.10 N

- Measure (measures initial length)

- Ramp 5 °C/min to 150 °C

Results

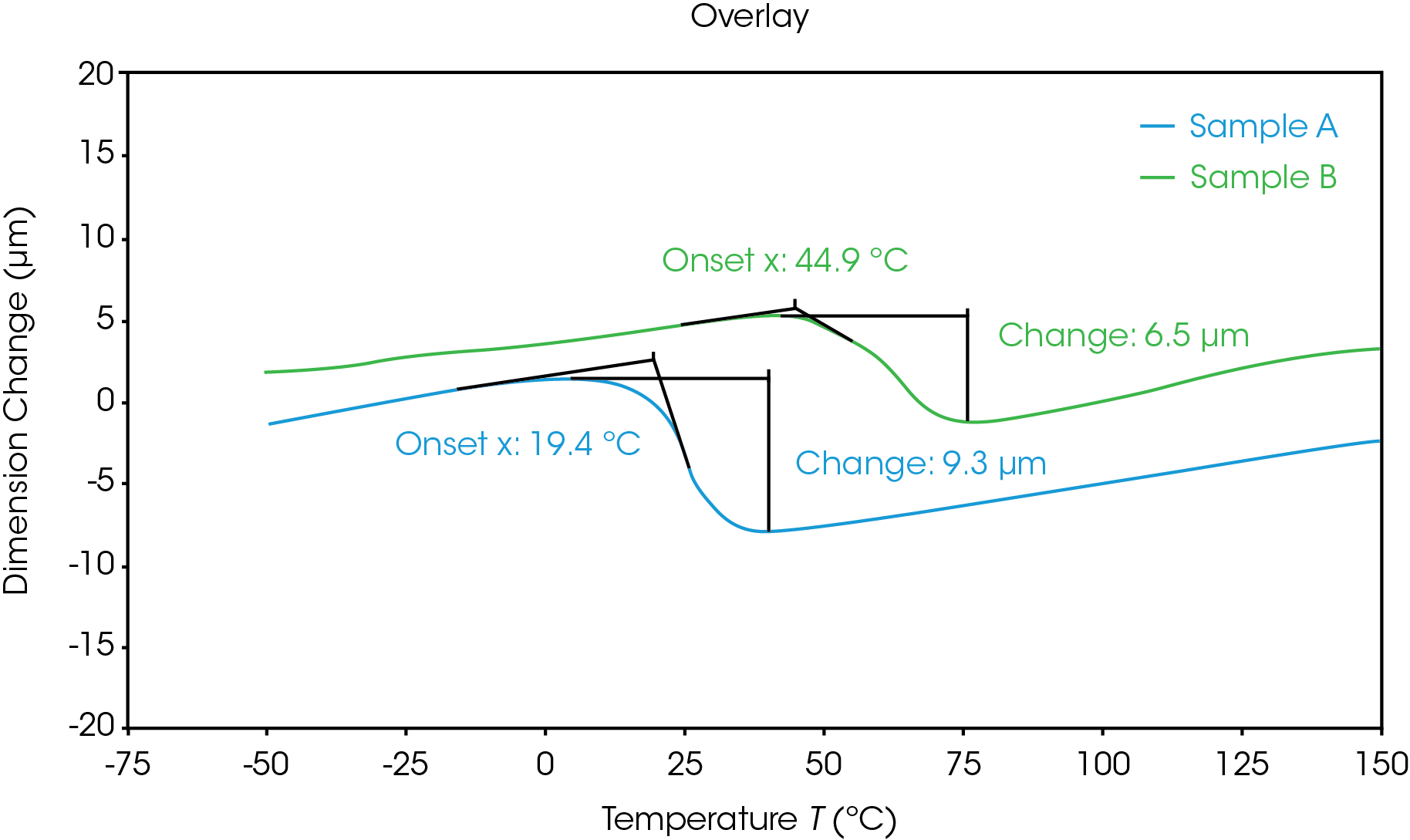

The data for both experiments are plotted in Figure 2 below. When using the penetration probe, the Tg is analyzed as the extrapolated onset of the change in dimension.

Sample A has a Tg of 19.4 °C and sample B has a Tg of 44.9 °C. Furthermore, sample A shows a dimensional change (penetration) of 9.3 µm, while sample B has a change of 6.5 µm. Based on the previous knowledge that a fully cured coating has a Tg around 45 °C, sample B appears to be fully cured, while sample A is under cured. This is also supported by the higher dimensional change at the Tg on sample A vs sample B.

Conclusions

The penetration probe of the Discovery TMA 450 allows for easy determination of the glass transition of a coating prepared on a panel. In addition to the glass transition temperature, the amount of penetration can be measured.

Acknowledgement

This paper was written by Louis Waguespack, Applications Laboratory Manager at TA Instruments.

Click here to download the printable version of this application note.