Keywords: Thermomechanical Analysis (TMA), Sample Size, Baseline Drift, Expansion, Contraction

TA418

Thermomechanical analysis (TMA) is a technique widely used to determine transition temperatures and expansion/contraction properties of materials, including the coefficient of thermal expansion (α). When determining α, however, there are three factors which need to be considered to obtain reproducible quantitative results. These are TMA sensitivity and baseline drift, sample thickness, and the magnitude of α.

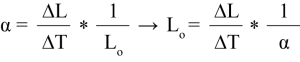

The TA Instruments TMA has a maximum sensitivity of 15 nm, a displacement resolution of 0.5 μm, and a baseline drift of 1 μm (typically, 0.5 μm between 0 to 500 °C). Therefore, the recommended measured sample dimensional change over this range for a determinations is >5 μm (roughly 10x the baseline drift). Knowing this, the minimum sample thickness required for testing can be determined from:

where:

∆L = measured dimension change

Lo = original sample thickness

∆T = temperature range of measurement

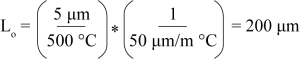

For example, a material with an expected α of 50 μm/m°C would yield a recommended minimum sample thickness for testing of:

This minimum sample thickness will obviously change with a and temperature range. Clearly, it is better to use samples much thicker than this minimum if possible, as this will further improve signal-to-noise ratio.

Acknowledgement

This applications note was submitted by Jon Foreman of the Applications Laboratory (US).

Click here to download the printable version of this application note.