Keywords: Heat Deflection Temperature (HDT), Thermomechanical Analysis (TMA), Deflection Temperature Under Load (DTUL), ASTM E2092

TA421

Introduction

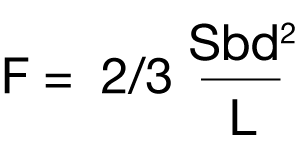

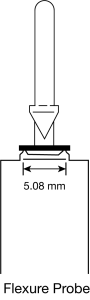

Heat Deflection Temperature (HDT) and Deflection Temperature Under Load (DTUL) are equivalent terms that reflect the temperature at which a material subjected to a three-point bending load deforms to a pre-determined position. The actual force applied to the sample and the amount of deflection required depend upon the sample geometry. ASTM E2092 and a related standard D648, defines a standard set of these parameters. The TMA flexure probe configuration (Figure 1) is utilized in this method.

ASTM E2092 defines DTUL as the temperature at which a precise strain (either 0.25 mm deflection or 0.20% strain as defined by sample dimensions in the procedure*) occurs under a specific stress (either 455 or 1820 kPa). With the TMA, the load (force) needed to achieve these stresses can be determined using equation (1).

where:

F = TMA Force (N)

S = Stress (MPa)

= 0.455 MPa (66 psi) or 1.82 MPa (264 psi)

b = Sample width (mm)

d = Sample thickness (mm)

L = Sample length = 5.08 mm (as defined by the flexure probe geometry, see Figure 1)

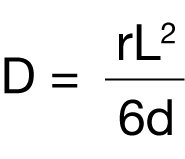

The TMA deflection equivalent to the ASTM specified % strain can be determined using the relationship shown in equation (2).

where:

D = TMA dimension change at center span (mm)

r = Sample strain = 0.0020 or 0.20%*

*[Sample strain computed based on sample dimensions and deflection change defined by ASTM E2092.

TMA Experimental Guidelines

- Thin samples (1 mm thick or less) are cut to appropriate dimensions (10 mm long x 3 mm wide).

- Samples are placed on the bending fixture and the knife-edged probe is lowered onto the sample with the predetermined force (F).

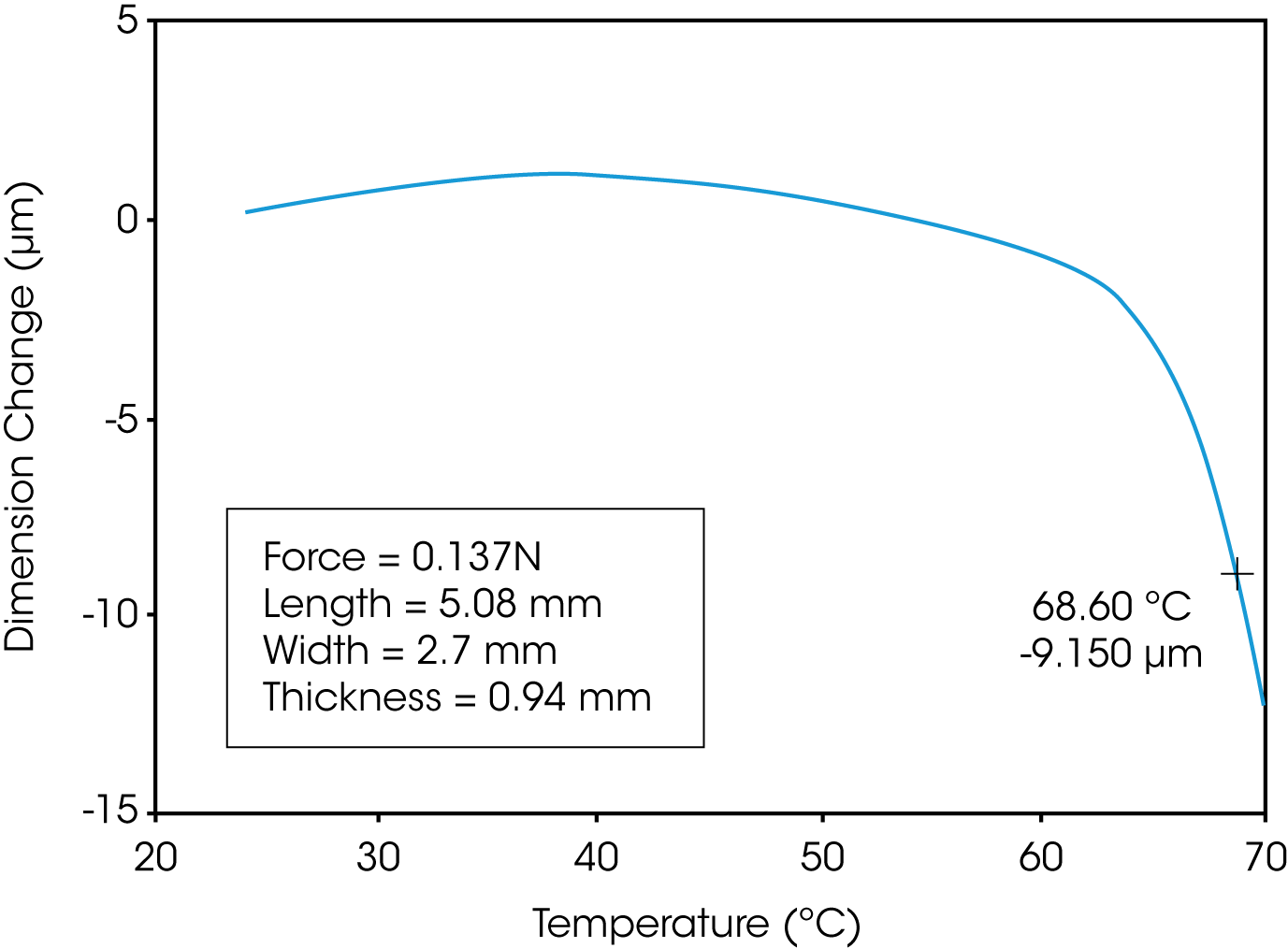

- The sample is heated at 2 ºC/minute until the required deformation is achieved as defined by equation (2).

- The temperature at the required deformation is recorded as the DTUL for the corresponding stress.

- An example of a DTUL experiment is shown in Figure 2 for Polyvinyl Chloride.

References

- ASTM Standard Test Method E2092 & D648.

Acknowledgement

TA Instruments | Waters Corporation

Click here to download the printable version of this application note.