動的機械分析とは

Andy Simon

July 09, 2024

はじめに

動的機械分析 (DMA) は、周期的応力を受けて変形する材料の機械的特性を測定するために使用される 熱分析技術です。 DMA は一般的に、ポリマー、複合材料、その他材料の粘弾性挙動を特定するために使用されます。

動的機械分析 (DMA) の仕組み

DMA は、サンプルに振動力を加えその応答を測定することで、材料の機械的特性を測定します。この技術により、材料の剛性と減衰特性を判定することができ、これはそれぞれ、貯蔵弾性率 (弾性応答) および損失弾性率 (粘性応答) として表されます。DMA はまた、材料の tan delta (損失弾性率と貯蔵弾性率の比率) を測定し、材料の減衰特性についての洞察を得るために使用することもできます。

動的機械分析が重要な理由

動的機械分析は、材料の機械的特性に関する必須の情報を提供してくれるため重要です。この情報は、様々な条件下で材料の性能と動作を把握するために不可欠です。この情報は幅広い用途で使用されるポリマー、複合材料、その他の材料の開発と品質管理において特に重視されています。

動的機械分析(DMA)の応用

DMA は次のような様々な産業やアプリケーションで使用されています:

- ポリマーおよびプラスチック:DMA は、ガラス転移温度、粘弾性挙動、ポリマーおよびプラスチックの機械的性能の研究に使用されています。この情報は、これらの材料の処理や性能特性を把握するために必須です。

- 複合材:DMA は、異なるコンポーネント間の界面接着や全体的な機械的性能など、複合材の機械的特性を評価するために使用されます。この情報は、高性能複合材料の設計と開発に重要です。

- 医薬品:DMA は、賦形剤や医薬品の活性成分の粘弾性挙動など、医薬品製剤の機械的特性の研究に使用されます。この情報は、医薬品の処理と性能特性を把握する上で重要です。

- 食品試験:DMA は、様々な配合の食感や安定性など、食品の粘弾性挙動の研究に使用されます。この情報は、食品の加工および性能特性を理解する上で必須です。

- 接着剤とコーティング:DMA は、粘弾性挙動や機械的性能など、接着剤やコーティングの機械的特性評価に使用されます。この情報は高性能の接着剤やコーティングの開発と品質管理に重要です。

動的機械分析 (DMA) 機器

DMA 機器は通常、次のコンポーネントで構成されています:

- サンプルホルダー:サンプルホルダーは、試験材料を固定します。サンプルホルダーは、引張、圧縮、屈曲、せん断など、さまざまな変形モードに合わせて構成できます。

- 振動試験装置:これは任意に設定した強制振動を発生させてサンプルを変形させる装置です。

- 変位センサー:変位センサーは、加えられた力に対する材料の反応を測定して、貯蔵弾性率、損失弾性率、tan delta などの機械的特性の算出を可能にします。

- 温度制御システム:温度制御システムは、サンプルの温度を正確に制御し、広範な温度範囲の材料特性研究を可能にします。

- データ収集および分析ソフトウェア:このソフトウェアは、DMA 機器からデータを収集・分析し、材料の機械的特性と動作について詳細な情報を提供します。

Discovery DMA 850

Discovery DMA 850 は、高度な材料特性評価のために設計された高性能 DMA 機器です。特徴:

- -150°C~600°C の広範な温度範囲。

- 張力、圧縮、屈曲、せん断など複数の変形モード。

- 粘弾性特性を正確に測定する高感度・高分解能。

- 包括的材料評価のための、高度なデータ収集および分析ソフトウェア。

RSA-G2 固体分析装置

RSA-G2 固体分析装置は、固体材料のレオロジー特性を測定するための最先端の機器です。特徴:

- 高度なモーターとトランスデューサー技術による精密な制御と測定。

- 平行プレート、コーンとプレート、ねじりなど、幅広いテスト形状に対応。

- 高温対応のため様々な熱条件下での材料研究が可能。

- 包括的なソフトウェアで詳細なレオロジー分析を実現。

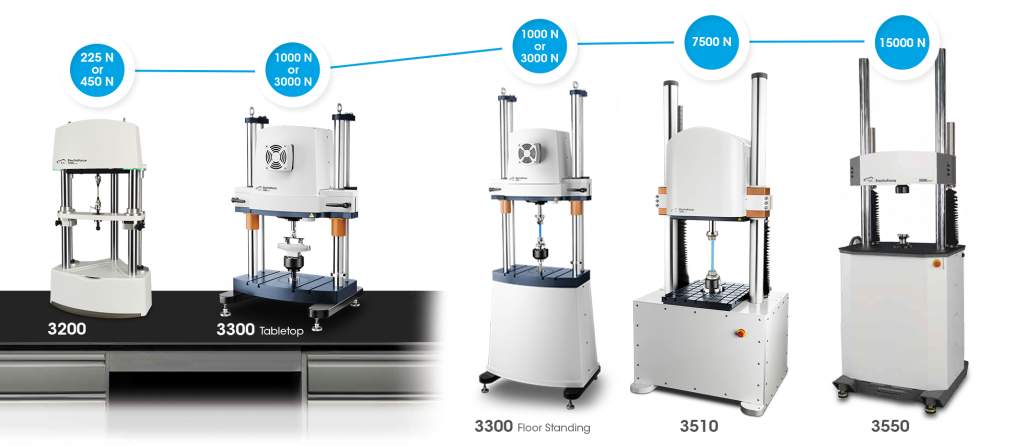

ElectroForce DMA 3200

ElectroForce DMA 3200 は、多目的に使える動的機械分析機器で、次のものを提供します:

- 正確な力と変位を制御する電磁アクチュエータ。

- 様々な動的条件下での材料研究に対応した幅広い周波数帯域。

- 引張、圧縮、屈曲など、様々な変形モードで試験が可能。

- 高度なソフトウェアによるデータの取得と分析。

ElectroForce 3550

ElectroForce 3550 は、幅広い用途に適した堅固な多目的機械試験機器です。特徴:

- 大型または硬いサンプルの試験に対応した高荷重機能。

- 正確で再現性の高い試験を可能にする電磁駆動。

- 疲労、耐久性、動的機械分析を含む多様な試験モード。

- 包括的なソフトウェアによるデータ収集と分析。

動的機械分析ソフトウェア

TRIOSソフトウェア

TRIOS ソフトウェアは DMA 機器専用に設計されており、ユーザフレンドリーなインターフェイスを使ったデータの取得、分析、レポート作成が可能です。主な特徴:

- リアルタイムのデータの視覚化と分析。

- 高度なデータフィッティングとモデリング機能。

- 詳細な分析レポートを生成するための包括的なレポートツール。

- 他の TA Instruments ハードウェアと統合することでワークフローの合理化が可能。

WinTest ソフトウェア

WinTest ソフトウェアは ElectroForce システムで使用するもので、堅牢な制御・分析機能を提供します。主な特徴:

- 試験パラメータを精密に制御して、正確で再現性のある結果を提供。

- 機械的特性の包括的評価を可能にする高度なデータ分析ツール。

- 幅広いアプリケーションに対応したカスタマイズ可能な試験プロトコル。

- ユーザーフレンドリーなインターフェイスで効率的に試験をセットアップおよび実行。

おわりに

参考文献:

- Groenewoud, W. M. (Ed.). (2001). Characterisation of Polymers by Thermal Analysis. Elsevier Science B.V. https://doi.org/10.1016/B978-044450604-7/50005-4