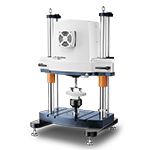

Planar Biaxial

The ElectroForce Planar Biaxial TestBench instrument offers superior control and unparalleled performance in material and soft tissue characterization. Using this instrument, you can assess mechanical anisotropy and stress-strain relationships in samples that range from engineered devices, including wearable sensors and wound repair meshes, to tissues such as skin, pericardium, and heart valve leaflets. This instrument can be configured with either two or four ElectroForce linear motors mounted on a horizontal baseplate and load cell options for each axis of loading